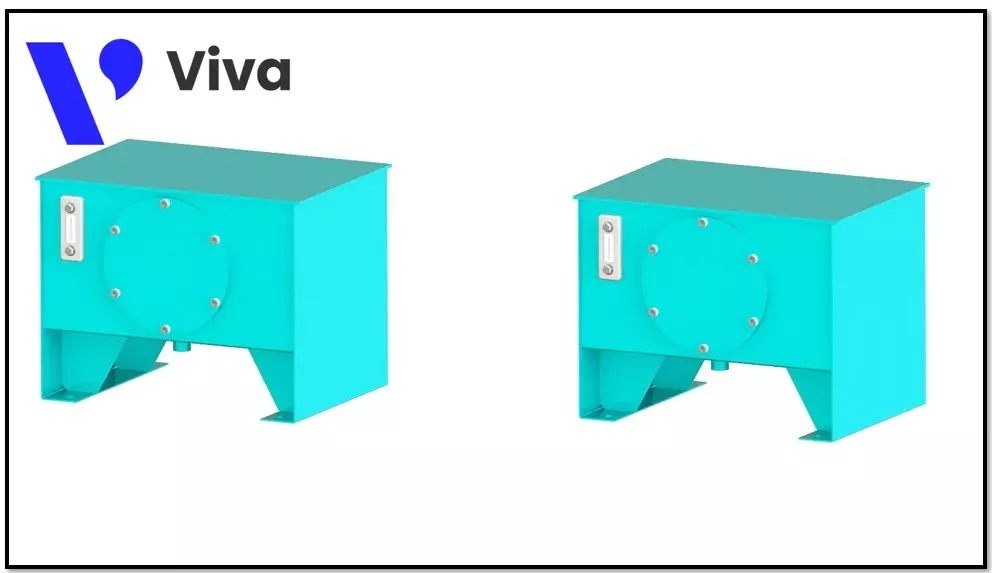

Hydraulic oil tank

Giá gốc là: 2.000.000 ₫.1.500.000 ₫Giá hiện tại là: 1.500.000 ₫.

Cập nhật lần cuối ngày 15/08/2025 lúc 04:59 chiều

Function of Hydraulic Oil Tank

As you may know, for a complete working system, one essential component is the fuel, which is similar to the blood flowing in our bodies. To supply an adequate amount of oil for the system to operate for a certain period, an indispensable device is the oil tank.

The function of the hydraulic oil tank is to store the oil used to operate the system. In addition to the important functions mentioned above, there are a few additional functions:

- Participate in the task of reducing the temperature of the oil by pumping the cooled oil back to the tank for further processes.

- The hydraulic oil tank is responsible for removing all the air present in the oil, ensuring that the oil always maintains the best quality.

- It also serves as a settling place for sediments contained in the oil, allowing them to settle at the bottom of the tank.

See more Hydraulic Hand Pump

Types of Oil Tanks Available Today

To serve different purposes, our company currently provides two types of oil tanks.

Stainless Steel Oil Tank

The stainless steel hydraulic oil tank is a product made entirely from stainless steel material, which offers numerous advantages. The greatest advantage of stainless steel material is its corrosion resistance and the bright appearance it provides to products made from it.

It allows users to place and use the product in various working conditions.

Currently, our company supplies stainless steel oil tanks in various sizes, ranging from 40 liters to 200 liters.

Steel Oil Tank

The steel oil tank is the second product, compared to the one made from stainless steel. The steel tank has slightly lower quality, which is why manufacturers need to apply an anti-rust paint layer to the tank’s surface. Especially when using a steel oil tank, you must ensure that the working environment is non-corrosive.

Construction of the Oil Tank

To create a complete product, many different components are required, and the same goes for the hydraulic oil tank. The following are the components used in constructing the oil tank.

Title: Footer: is a component used to separate the body part from the ground below, avoiding surface corrosion over time.

Dipstick: This is an extremely important device, through which users can determine the condition of the oil inside the tank.

Oil filter cap: Usually, the cap is designed to have the ability to filter oil continuously during the oil pouring process into the container. This device is made from stainless steel material to provide high durability.

Formula for calculating the volume of an oil tank

For devices used to store or contain liquids, volume is an extremely important parameter. It allows users to determine the appropriate product selection for practical use.

To accurately and quickly determine the storage volume of a product, there is no other way but to rely on the volume calculation formula.

V = (3-5) x Q x 110%

V is the storage volume of the hydraulic oil tank, which must be three to five times the pump flow rate per minute, plus 10% of the volume for air expansion.

From the formula above, we can see that to calculate the volume, we need to determine several relevant parameters clearly.

For example, the minimum oil level in the tank, which you may not know that every system requires a minimum oil level. This is to ensure that the oil pipelines are not mixed with air.

Real space: is the space used to install the tank, from which we can determine the correct pump installation method.

Continue reading hydraulic electric pump

ĐÁNH GIÁ SẢN PHẨM

Đánh giá

Chưa có đánh giá nào.