CF8 stainless steel

CF8 Stainless steel is a type of material widely used in many fields, particularly in the fabrication of industrial valves, components, and machine parts.

If you frequently work with pipeline systems, offshore and coastal construction systems, you have probably come across the material symbol “CF8” in many related technical documents or marked on various equipment. And if you are wondering what the “CF8” symbol represents, this article will provide you with a satisfactory answer and useful information.

What is CF8 material?

CF8 material is a type of austenitic stainless steel, primarily composed of iron (Fe), chromium (Cr), and nickel (Ni), with a few other elements in small quantities within the material.

In English, it is referred to as “Cast Stainless Steel CF8,” and in Vietnam, it is commonly known by names such as:

- CF8

- Thép CF8

- Thép không gỉ CF8.

CF8 stainless steel has many properties similar to stainless steel 304, and in practice, these two materials are often used interchangeably. However, it should be noted that they are two different types of materials.

Chemical Composition

CF8 stainless steel is composed of various metallic and non-metallic elements. The specific composition and content of the constituents in this type of material may vary slightly depending on the manufacturing unit. However, the most common chemical composition formula of CF8 stainless steel is as follows:

- Carbon content: C ≤ 0.08%

- Chromium content: Cr from 18 to 21%

- Iron content: Fe from 63.8 to 74%

- Manganese content: Mn ≤ 1.5%

- Molybdenum content: Mo ≤ 0.5%

- Nickel content: Ni from 8 to 11%

- Silicon content: Si ≤ 2%

- Sulfur content: S ≤ 0.04%

Characteristics

Like any other type of material, the characteristics of a material are important information used for:

- Evaluating its compatibility with fluids and the surrounding working environment based on its chemical properties.

- Calculating and designing products based on mechanical properties.

- Designing overall systems based on physical properties.

- CF8 stainless steel possesses the following characteristics:

- Tensile strength: 485 MPa

- Elongation at break: approximately 35%

- Hardness: 134 to 196 HB

- Weldability: Good (post-weld heat treatment is required to ensure the strength of the weld joint)

- Castability: Good

- Machinability: Good

- Corrosion resistance: Resistant to corrosion by certain chemicals, weak acids, or low-concentration acids.

- Oxidation resistance: The material does not oxidize under normal working conditions.

The Difference between CF8 Steel and Stainless Steel 304

In various equipment applications or material selection for fabrication, you are often advised on stainless steel 304 and CF8 stainless steel, which are said to have similar properties. In many cases, it is even claimed that they are the same type of material. Let’s find out if this is true.

Based on the information I have researched from the website matweb.com and publicly available data from several stainless steel manufacturers worldwide:

The composition of CF8 stainless steel and stainless steel 304 has many similarities. They are both composed of elements such as Fe, C, Cr, Mn, Si, S, P, and Ni, and the content of these elements is relatively equal.

However, there is a slight difference here. CF8 stainless steel, manufactured according to standards including UNS J92600 and ASTM A351, usually contains a small amount of molybdenum (Mo), with a content of less than or equal to 0.5%.

In terms of mechanical properties, stainless steel 304 has a tensile strength of about 505 MPa, while CF8 stainless steel has a tensile strength of 485 MPa. The elongation at break of stainless steel 304 is approximately 70%, while CF8 has an elongation of about 30% to 35%.

Considering these differences, we can conclude that CF8 stainless steel and stainless steel 304 (inox 304) are different types of materials. However, they have similar properties in many aspects, and the interchangeability between these two materials is possible with careful calculation and selection by experts.

Advantages of CF8 Stainless Steel

CF8 stainless steel has notable advantages, including:

- Corrosion resistance: It has excellent corrosion resistance in various environments, including surface corrosion, chemical corrosion, and electrochemical interaction corrosion. This makes it suitable for applications in industries such as chemical, petroleum, water treatment, and other corrosion-related environments.

- High strength: CF8 steel has high strength, especially in high-pressure and high-temperature environments. It has good load-bearing capacity, allowing it to operate stably in harsh conditions.

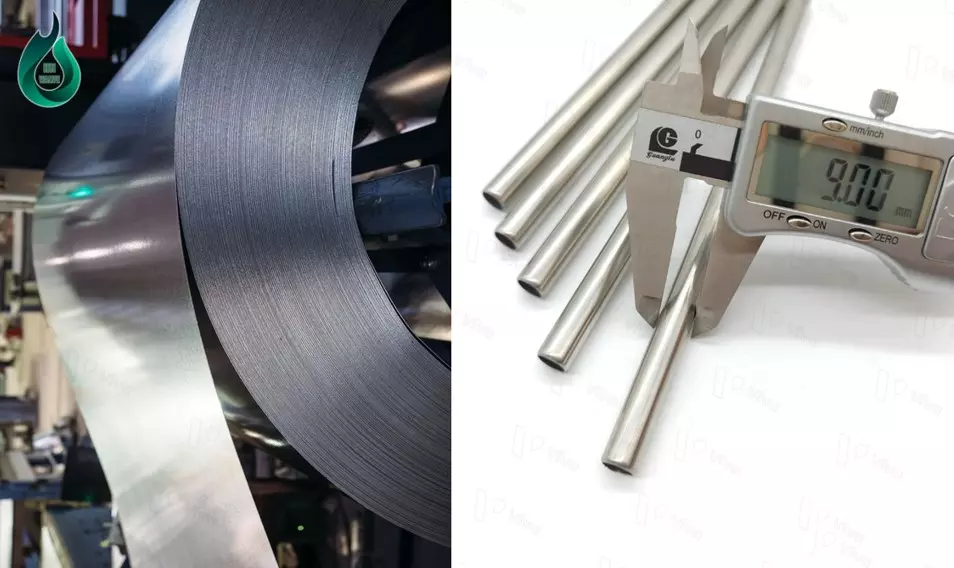

- Processing flexibility: CF8 stainless steel has good processing capabilities, allowing it to be cast and machined into various shapes and sizes. It can be welded, turned, milled, ground, and processed using cutting machines to create complex, high-precision components.

Limitations of CF8 Stainless Steel

- Although CF8 stainless steel has many advantages, it also has some limitations to consider:

- Limitations in highly corrosive environments: While it has good corrosion resistance, it is not suitable for highly corrosive environments such as high-concentration hydrochloric acid, high-concentration sulfuric acid, or environments containing chlorine.

- Limitation in hardness: CF8 steel has limited hardness compared to some other stainless steels.

- Cost: Compared to some other materials, CF8 stainless steel may have a higher cost. This can affect material choices in cost-sensitive applications.

Applications of CF8 Stainless Steel

Based on the advantages and limitations of CF8 stainless steel, it is particularly suitable for manufacturing various types of machinery and equipment used in pipeline construction, saltwater contact applications, and direct chemical contact applications.

Some practical examples of the application of CF8 stainless steel include:

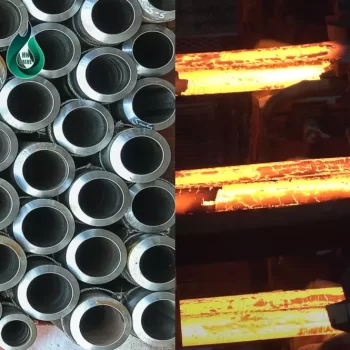

- Machine fabrication: With its excellent casting ability, CF8 stainless steel is used to manufacture structural components of machines, such as machine covers, shaft components, gears, and various other detailed parts. It is preferred for parts that need to work in corrosive conditions.

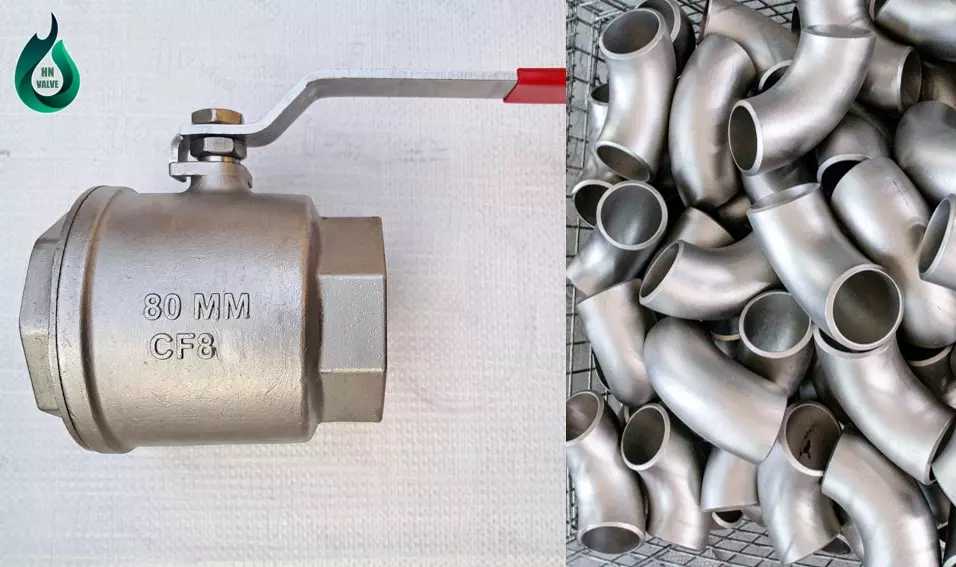

- Valve manufacturing: CF8 stainless steel is commonly used to manufacture different types of valves, including ball valves, butterfly valves, gate valves, and check valves. It is particularly suitable for fabricating parts that directly interact with the flowing medium, including valve bodies, valve discs, and stems.

- Pipeline and pipe fittings: With its corrosion resistance and high-pressure and high-temperature capabilities, CF8 stainless steel is suitable for use in fluid, gas, and steam conveying pipeline systems. It is used to manufacture pipes with diameters ranging from DN8 to DN500 and beyond. It is also used for fabricating various types of pipe fittings such as flanges, couplings, tees, and elbows.

- Oil and gas industry: CF8 steel is commonly used in oil and gas applications, including pipe systems, valves, plates, pressure-bearing components, and equipment involved in the exploration, production, and transportation of oil and gas. Its corrosion resistance and heat resistance enable it to perform well in the harsh environments of the oil and gas industry.

- Food industry: CF8 stainless steel is chosen as a fabrication material for various equipment in contact with liquids during food processing and production. Its corrosion resistance and oxidation resistance make it suitable for manufacturing tanks, pipes, and various types of valves used in the food industry.