Stainless steel 316

Learn about stainless steel 316

Stainless steel 316 is a type of stainless steel that contains a high amount of chromium, nickel, and molybdenum. This type of material is highly regarded for its corrosion resistance (better than stainless steel 304), strength, heat resistance, safety, and ability to resist oxidation in various working conditions.

With its outstanding advantages, it is applied in the fabrication of various equipment and tools, related to fields including household appliances, machinery parts and components, medical devices, various valves and pipes used in saltwater environments, etc.

The characteristics of stainless steel 316 vary based on the content of its components and the steelmaking process. Manufacturers can add or reduce the content of basic elements or incorporate other metal components to enhance certain features such as strength, heat resistance, chemical resistance, etc., to suit specific purposes.

Chemical composition of stainless steel 316

For standard stainless steel 316, the composition of its constituents and the content measured by weight are as follows:

- C: Carbon content C ≤ 0.05%

- Si: Silicon content Si ≤ 0.75%

- Mn: Manganese content Mn ≤ 2%

- P: Phosphorus content P ≤ 0.04%

- Cr: Chromium content Cr from 16.5% to 18%

- Ni: Nickel content Ni from 10.5% to 12%

- Mo: Molybdenum content from 2% to 2.5%

- Fe: Iron content Fe from 61.8% to 72%.

| C | Si | Mn | P | Cr | Ni | Mo | Fe |

| C ≤ 0.05% | 0.75% | Mn ≤ 2% | P ≤ 0.04% | 16.5% to 18% | 10.5% to 12% | 2% to 2.5% | 61.8% to 72% |

Properties of stainless steel 316

As mentioned above, the properties of stainless steel 316 vary to some extent depending on the variation in the chemical composition as well as the steelmaking technology. However, these differences are within permissible limits.

The basic properties of stainless steel 316 are as follows:

- Tensile strength: 550 MPa

- Elastic modulus: 193 GPa

- Hardness: 217 HB

- Elongation at break: 60%

- Electrical resistivity: approximately 0.000075 (Ω.cm) at 20℃ (note that as the temperature increases, the electrical resistivity also increases).

- Corrosion resistance: against gasoline, oil, 20% phosphoric acid at boiling temperature, 20% sulfuric acid at room temperature, etc.

- Maximum working temperature: Up to 870℃.

Classification of stainless steel 316

Stainless steel 316 is a type of material used in various fields due to its outstanding advantages. In order to meet the demands for different purposes, Stainless steel 316 is supplied in various variants, or we can call them different types.

The classification of stainless steel 316 is based on several aspects, and in this article, we will discuss two popular classification types.

Classification based on Carbon content

Carbon is an element always present in the composition of various steels, including stainless steel. Its role is to increase hardness and strength when combined with iron. However, with a high content, it makes the material more brittle.

For stainless steels, a high carbon content promotes the formation of chromium carbides, making the stainless steel more susceptible to corrosion. However, this only occurs under sufficiently high temperatures (such as during the welding process or under certain special conditions). Therefore, the classification of stainless steel 316 based on carbon content is quite common.

Stainless Steel 316L

Stainless Steel 316L is understood as low carbon stainless steel (L – Low), with the carbon content in the material typically limited to 0.03% (calculated on the overall weight of the material). Stainless Steel 316L has lower mechanical properties compared to Stainless Steel 316H (lower tensile strength and lower load-bearing capacity), but the differences are not significant.

Due to its low carbon content, there is a common misconception that Stainless Steel 316L has better corrosion resistance. However, in reality, this is not true. The corrosion resistance of Stainless Steel 316L and Stainless Steel 316 is essentially the same. However, Stainless Steel 316L is highly regarded in terms of welding technology, as the weld joint of 316L is less prone to corrosion (corrosion from within the weld joint) compared to Stainless Steel 316.

Stainless Steel 316H

Stainless Steel 316H is a high carbon stainless steel (H – High), with the carbon content in the material ranging from 0.04% to 0.1%. The addition of carbon helps increase the tensile strength limit of the material and improves stability at high temperatures.

The limitation of this type of stainless steel is that the weld joints of the material often have low strength. To overcome this issue, the weld joints of Stainless Steel 316 and Stainless Steel 316H usually undergo an annealing process.

Classification based on chemical composition

In addition to the standard elements that make up this type of material, Stainless Steel 316 also incorporates other elements to improve certain aspects of its performance, making it suitable for specific application requirements.

Stainless Steel 316Ti

Stainless Steel 316Ti is supplemented with titanium to improve the mechanical properties of the material. Additionally, the titanium content in the material acts as a barrier to the formation of chromium carbides, thereby enhancing the weldability of the material.

Stainless Steel 316N

Stainless Steel 316N is supplemented with nitrogen (N). Nitrogen is added to enhance the crystalline structure of the material, improving its mechanical properties and stress resistance, particularly in high-pressure environments.

Stainless Steel 316N has similar corrosion resistance to Stainless Steel 316 but with better stress resistance, especially in environments containing chlorine and high-pressure conditions. It is suitable for applications requiring flexibility and good stress resistance under harsh conditions.

Stainless Steel 316LN

Stainless Steel 316LN is a low-carbon version that is also supplemented with nitrogen, improving the mechanical properties of the material. This ensures that the weld joint of Stainless Steel 316LN has high strength while maintaining good mechanical properties.

Strengths and Limitations of Stainless Steel 316

Strengths of Stainless Steel 316:

- Corrosion resistance: It has good corrosion resistance and can be directly used with certain types of acids at specific concentrations and other corrosive substances.

- Good mechanical properties: It has high tensile strength and relatively good hardness, with material elasticity and flexibility that allow for stretching.

- Temperature resistance: It can withstand temperatures up to 800℃.

- Technological properties: Stainless Steel 316 is considered to have good technological properties and can be processed using various cutting methods (turning, milling, drilling, etc.). The material has good weldability (with attention to versions with high carbon content, requiring post-weld annealing to ensure weld strength). Additionally, there are many other machining and surface protection technologies that can be applied to Stainless Steel 316.

- Diverse types: It is available in various variants with different carbon content ratios, additional alloying elements, and a wide range of shapes and forms on the market, including sheets, solid bars, and tubes.

Limitations of Stainless Steel 316:

- Cost: Stainless Steel 316 has a higher cost compared to some other types of stainless steel, especially when compared to Stainless Steel 304.

- Weldability: While it can be welded, versions with high carbon content may result in weld joints that do not guarantee the desired strength if not properly handled using appropriate techniques.

Applications of Stainless Steel 316

Stainless Steel 316 has numerous applications in various industries, thanks to its corrosion resistance, good stress resistance, and good technological properties.

Here are some common applications of Stainless Steel 316:

- Oil and gas industry: Used in equipment within the oil and gas system, such as pipelines, storage tanks, valves, and connecting components. For offshore drilling rigs, Stainless Steel 316 is used to fabricate parts and structures in contact with seawater due to its excellent corrosion resistance.

- Medical field: Stainless Steel 316 is considered a safe material for human health and is used in the manufacturing of medical devices such as surgical blades, scissors, and parts of endoscopic instruments.

- Food industry: In the food industry, Stainless Steel 316L is widely used, with many accessories and equipment used in sanitary systems fabricated from this material. This includes sanitary butterfly valves, sanitary clamps, and sanitary fittings.

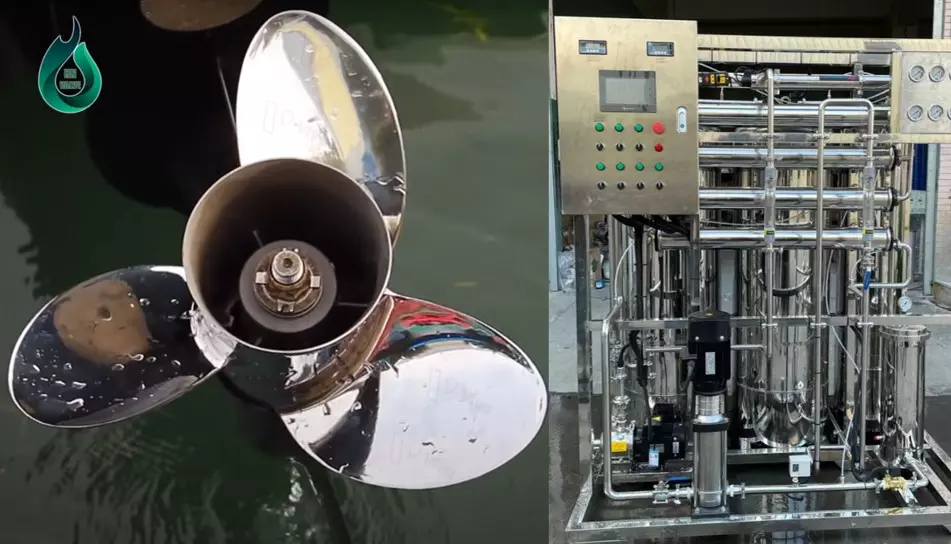

- Machine fabrication: Stainless Steel 316 is used to fabricate various parts and components related to different types of machinery, including bolts, propeller shafts for boats, and machine shafts.

- Construction and architecture: It is used in architectural and construction applications such as railings, doors and windows, exterior cladding, and decoration. It provides aesthetic appeal and high durability, especially in outdoor environments, due to its corrosion resistance in harsh weather conditions.

In addition, Stainless Steel 316 is also used in many other industries, including electronics, renewable energy, mining, water treatment, and more.

Conclusion

Stainless Steel 316, a type of stainless steel, is an important material with high applicability.

With many advantages such as chemical resistance, corrosion resistance, resistance to oxidation under normal conditions, heat resistance, stress resistance, and high technological properties…

This makes it suitable for various applications in industries such as oil and gas, chemicals, medical, food and food processing, construction, and maritime.

However, Stainless Steel 316 also has some limitations, including a higher cost compared to some other types of stainless steel, susceptibility to corrosion when in contact with strong acids at high concentrations, and increased corrosion at elevated temperatures.

Therefore, the selection and use of Stainless Steel 316 should be carefully considered based on the specific requirements of each application and working conditions.

The information shared in this article is compiled by the author from various sources: acerinox.com, atlassteels.com.au, stainless-steel-world.net, combined with the author’s personal experience.

If you have any questions regarding the article, please leave your inquiries in the comments section. We warmly welcome any contributions and feedback on this article. Thank you for taking the time to read!