PP plastic

Nhựa pp is a material used in many applications, among which the most commonly encountered is the production of various types of food containers.

This is easily recognizable because on food containers, it is marked with the symbol of number 5 inside a triangular symbol with a recycling arrow (meaning that this material is recyclable).

So what is PP plastic? Is this material safe? Its applications in daily life? and other related information, let’s find out more right away.

What is PP plastic?

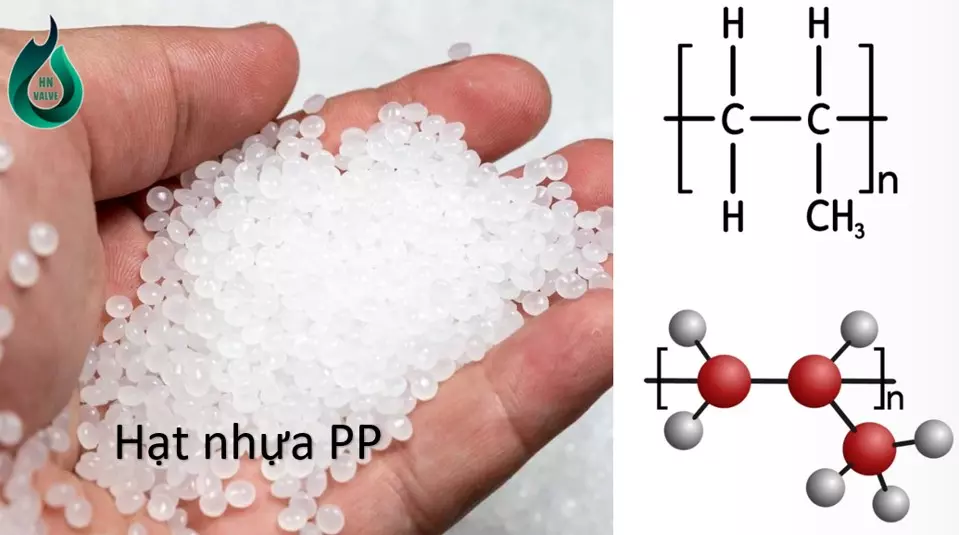

PP plastic (Polypropylene) is a type of synthetic plastic with the chemical formula (C3H6)n. In its natural state (without adding colorants), this material is translucent or opaque white, and its flexibility depends on the production process. In many cases, PP plastic is also referred to as plastic number 5, as it is the identification number for PP plastic in the classification of seven common types of plastics.

Polypropylene is used as a manufacturing material in various fields due to its outstanding characteristics:

- It has excellent corrosion resistance, chemical resistance, and resistance to oxidation.

- It is water-resistant and does not absorb water.

- It has good heat resistance.

- It has suitable mechanical strength and hardness, making it applicable in various industrial and daily life uses.

- It is easily recyclable and environmentally friendly.

Is PP Plastic Safe?

When using and handling products made from plastic, especially those used to directly contact with food, we often ask questions like: What type of plastic is this? Is it safe?

And if you didn’t know, PP plastic is commonly used to manufacture food containers, medicine boxes, yogurt cups, various types of packaging, and more. You can rest assured because PP plastic is considered safe. This material is non-toxic when in contact with food under normal conditions and even when exposed to temperatures up to 100°C.

So, if you are using food containers made from PP plastic (marked with the number 5 inside the recycling triangle symbol), you can confidently store hot food, take them on the go, or use them for similar applications, as it is not harmful.

Properties of PP Plastic

In essence, PP plastic is considered a durable and flexible material. Under normal conditions and when naturally produced, this type of material exhibits the following characteristics:

- Density: 0.905 g/cm³

- Maximum continuous use temperature: 80℃

- Chemical resistance to: Dilute acid, dilute alkali, alcohol

- Melting temperature: From 135 to 165℃

- Tensile strength: 0.95 to 1.3 N/mm²

- Elongation at break: 150 to 300%

- Electrical insulation: Yes

- Flame resistance: No (PP plastic is highly flammable)

How to Identify PP Plastic

During usage and trading, it’s important to distinguish between different types of plastics. Depending on specific requirements, we can use one or combine multiple methods to identify PP plastic.

Observe the Symbol

Typically, products made from plastic, which are recyclable, are marked with numbers ranging from 1 to 7. PP plastic is identified by the number 5.

Floatation Method

The floatation method for material classification is quite simple and easy to perform, but it does not yield high efficiency. The principle of this method relies on the difference in density among different types of plastics.

With PP plastic, when it is placed in water, it will float because its density is around 0.905 g/cm³, compared to the density of water which is 1 g/cm³. On the other hand, PET plastic, with a density of approximately 1.38 g/cm³, will sink in water.

The same principle applies to other types of plastics. However, this method is not highly effective and can only be used to distinguish between plastics with densities greater than and less than that of water.

Burning Method

To easily and effectively differentiate PP plastic, the simplest method is through burning. Due to the different compositions of various plastics, different reactions occur during combustion, leading to observable differences.

- PVC (Polyvinyl Chloride) plastic: It is very difficult to ignite and does not sustain combustion. If it burns for a sufficient time, a smell of chlorine will be detected.

- PET (Polyethylene Terephthalate) plastic: It ignites easily and can self-sustain combustion. The flame burns with a yellowish color and produces many bubbles. It emits a distinct odor similar to burnt sugar.

- PP plastic: It burns easily and produces dripping molten plastic. It has a smell resembling that of waste oil.

Differentiating PP plastic based on the burning method is relatively effective. However, this procedure requires appropriate sample preparation, as applying it directly to the product may cause damage. Furthermore, when performing this method, safety rules must be strictly followed to avoid fire hazards and burns to the person carrying it out.

Applications of PP Plastic

You may already know that PP plastic is one of the seven commonly used types of plastics nowadays, as it possesses various advantages, such as safety, impact resistance, heat resistance, and low cost. These reasons contribute to its widespread use.

Some examples of Polypropylene applications include:

- Household items: One of the most easily recognizable applications is in food containers, various bottles, and some household tools.

- Packaging: Serving similar purposes as food containers, packaging materials are also often made from PP plastic.

- Textiles and apparel: PP plastic is processed into small fibers used for weaving fabrics. PP fabric is used in making furniture, certain car parts, etc.

- Roofing and insulation panels: PP’s water resistance and ability to withstand harsh environmental conditions make it suitable for producing roofing sheets, insulation panels, and waterproofing materials.

- Medical packaging: PP’s chemical resistance and antimicrobial properties make it suitable for producing medical packaging materials.

- Machinery equipment: This material is used to manufacture various parts and components of different machines. Especially for parts that require electrical insulation, heat resistance, or act as buffers between different parts and components.

Conclusion

In this article, we have explored various information related to PP plastic, such as its safety, the markings on PP plastic products, properties, and applications.

I hope that the information provided in this article has been helpful to you in some way.

As always, I warmly welcome feedback from readers regarding this article, and any related questions will be addressed by the author as soon as possible in the comment section.

Thank you!