Compressed air pressure regulating

Giá gốc là: 150.000 ₫.130.000 ₫Giá hiện tại là: 130.000 ₫.

Cập nhật lần cuối ngày 15/08/2025 lúc 04:38 chiều

Pneumatic regulator valve, an important device used in most small and large compressed air systems. In this article, we will explore the related information about this type of valve and why it is used so much.

Introduction to Compressed Air Pressure Regulating Valve

Compressed air pressure regulating valves are used in compressed air systems to regulate the pressure of compressed air after passing through the valve. The pressure of the compressed air can be adjusted to its maximum level based on the input pressure, and the minimum pressure is 0 (completely blocking the passage of air). Pressure adjustment is carried out through the pressure adjustment knob located on top of the valve body.

The valve body is made of durable solid aluminum alloy, capable of withstanding high pressure and resisting oxidation. The pressure gauge installed on the valve body indicates the compressed air pressure, making it easier for users to adjust the pressure level as needed.

Compressed air pressure regulating valves are typically installed individually on the compressed air pipeline (providing the function of adjusting the output pressure of the compressed air) or integrated with compressed air filter products (providing the function of filtering clean compressed air and regulating the pressure of compressed air after passing through the valve).

Why is it necessary to use compressed air pressure regulating valves?

A compressed air system is composed of multiple components and devices, each of which has its own specific functions and tasks. Therefore, the compressed air used for these components will have different pressure requirements. Additionally, for various types of pneumatic devices, the magnitude of the operating compressed air pressure directly affects the device’s operation mode.

To control the operation of pneumatic devices within the system and ensure that each component receives a suitable airflow with the proper pressure, compressed air pressure regulating valves have been designed and manufactured. These devices have the ability to easily adjust the pressure, with simple adjustment operations and easy and quick installation and removal from the air pipelines. They are suitable for all types of systems.

Basic Specifications of Compressed Air Pressure Regulating Valve

A compressed air pressure regulating valve is a device used in engineering systems to ensure efficient and safe operation of various equipment. To achieve this, careful attention needs to be given to the design specifications of the product. Since this is a diverse product range, we have compiled the specifications of commonly used devices as follows:

- Product: Compressed Air Pressure Regulating Valve

- Valve body material: Brass, stainless steel, or aluminum alloy

- Working pressure range: 10 bar, 16 bar, 20 bar, etc.

- Permissible working temperature range: From -20℃ to 70℃

- Connection type: NPT thread, PT thread

- Thread diameter: 1/8″, 1/4″, 1/2″, etc.

- Working medium: Compressed air

- Brands: Airtac – Taiwan, STNC – China, Festo – Germany, etc.

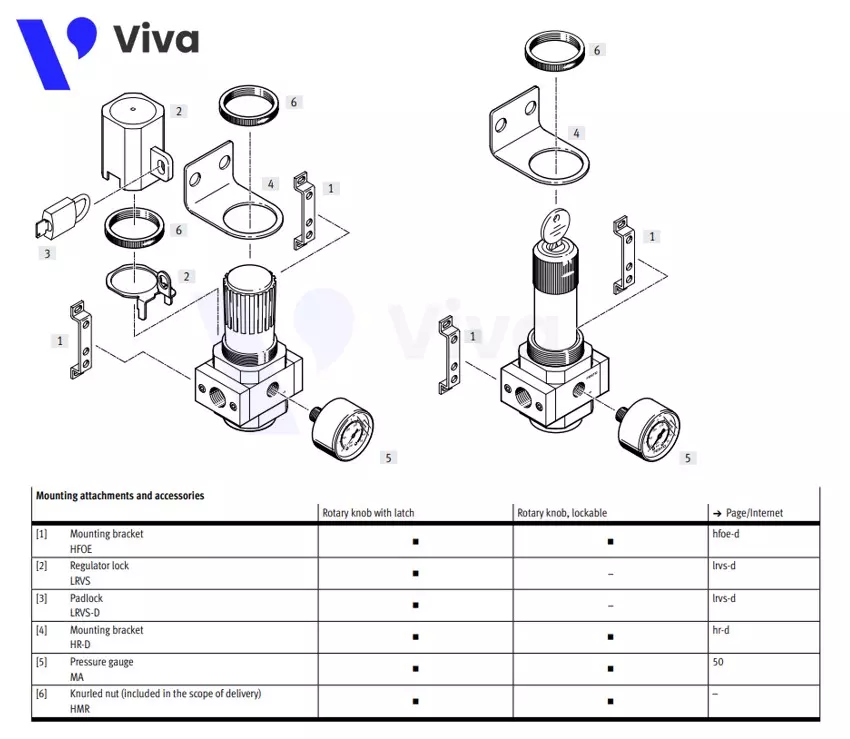

Structure of Compressed Air Pressure Regulating Valve

The structure of a compressed air pressure regulating valve depends on the specific product type, as they are manufactured by various brands, each offering different models to optimize the device’s performance in practical applications.

In essence, a compressed air pressure regulating valve consists of the following main components:

- Valve body: The valve body is typically made of aluminum alloy. Inside the valve body, there are two chambers separated by a valve disc. The valve body is designed with ports connected to the compressed air pipelines, and it serves to link all the components together into a complete entity.

- Pressure adjustment knob: The pressure adjustment knob is designed on the valve body to adjust the pressure of the compressed air after passing through the valve. Rotating the adjustment knob will affect and change the force exerted on the valve diaphragm by the spring.

- Pressure gauge: The pressure gauge is installed on the valve body to measure the output pressure of the compressed air. Users can adjust the compressed air pressure easily and accurately based on the readings from the pressure gauge.

- Spring: This component applies force to the valve stem and acts as the opening force of the valve. It opposes the force generated by the compressed air pressure acting on the valve diaphragm.

- Diaphragm: The diaphragm, a resilient component, separates the two chambers of the pressure regulating valve. The valve diaphragm directly contacts the compressed air on the outlet side, and the pressure of the compressed air creates a force that counteracts the spring force.

- Valve stem: The valve stem is connected to the valve disc, and one end is connected to the diaphragm.

- Valve disc: The valve disc is the component directly responsible for opening and closing the flow of compressed air.

- Associated mounting accessories: Mounting accessories include various small components that are used to secure the pressure regulating valve in a specific position.

Types of Compressed Air Pressure Regulating Valves

Integrated Filter Regulating Valve

Compressed air pressure regulating valves with integrated filters combine two functions in one device: the ability to adjust the working pressure of the compressed air and the ability to filter out impurities present in the compressed air.

The integration of these two functions helps save on manufacturing materials, installation space, and reduces the number of devices used in a system. This is particularly beneficial for complex systems.

Basic Pressure Regulating Valve

Basic compressed air pressure regulating valves, also known as pressure reducing valves, are designed with a single function: to adjust the pressure of the compressed air as it passes through the valve. Due to their fewer functions, these devices have a simpler structure.

Some Brands of Compressed Air Pressure Regulating Valves on the Market

Airtac Compressed Air Pressure Regulating Valve

Airtac is a well-known brand among Vietnamese users when it comes to compressed air devices. This brand from Taiwan has been engaged in the manufacturing and fabrication of various compressed air devices for over 30 years. Their products have been present in many countries and regions, including the demanding European market.

Airtac’s compressed air pressure regulating valve products come in various models, capable of meeting diverse working conditions. Additionally, their products are competitively priced compared to many other brands, making them highly regarded in the affordable price segment.

SMC Compressed Air Pressure Regulating Valve

SMC compressed air pressure regulating valves are products supplied by the manufacturer SMC from Japan.

The company was established on April 27, 1959, with its headquarters located in Tokyo and multiple production plants situated in around 30 different countries. The company operates in the manufacturing of various types of automatic control equipment, pneumatic devices, and power transmission equipment.

SMC’s compressed air pressure regulating valve products have been used for many years in industrial compressed air systems in Vietnam. They are highly regarded for their quality, although the price of the products is relatively high.

Festo Compressed Air Pressure Regulating Valve

Festo compressed air pressure regulating valve is a product line originating from Germany. Festo is a large brand with a product market that is globally recognized. Since its establishment in 1925, Festo has built a product distribution system in 176 countries.

Festo compressed air pressure regulating valve is a high-end product line used in modern systems that require high precision and stability. These products exhibit high levels of refinement.

In the Vietnamese market, Festo compressed air pressure regulating valves are classified as premium products, which is why they often come with a high price tag compared to the general market.

See more products compressed air filters.

ĐÁNH GIÁ SẢN PHẨM

Đánh giá

Chưa có đánh giá nào.