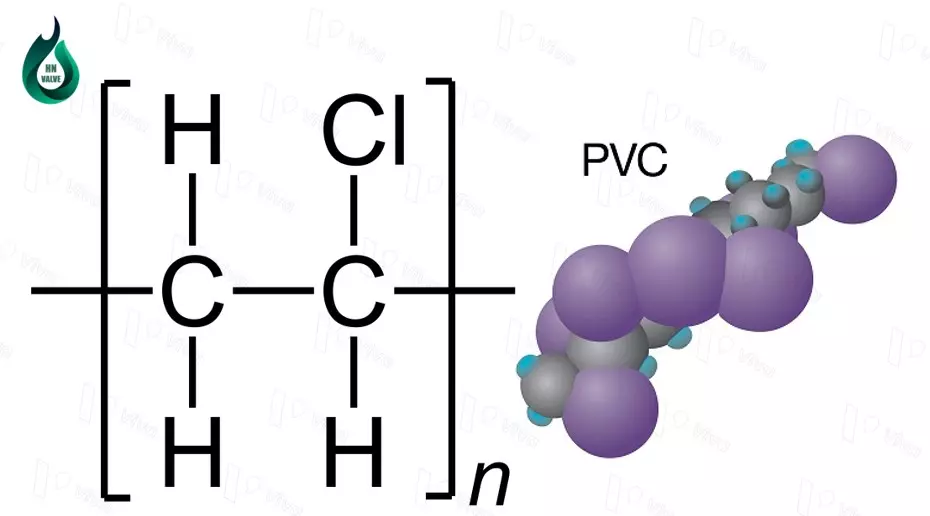

PVC

What is PVC?

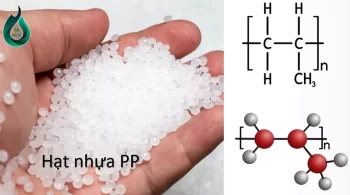

PVC (Polyvinyl chloride) is a synthetic plastic composed of vinyl chloride (C2H3Cl) units. It is one of the most commonly used plastics and finds widespread applications in various fields.

PVC has notable characteristics including hardness, durability, fire resistance, chemical resistance, and a certain degree of elasticity.

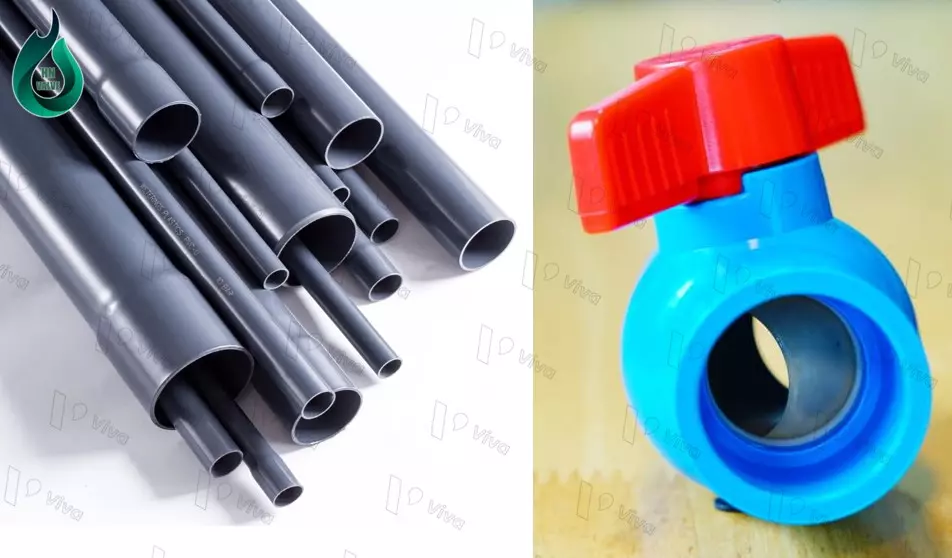

With these special properties, PVC is used in numerous applications, including water pipes, oil conduits, insulation components, steam hoses, thermal and acoustic insulation materials, construction materials such as wall panels, doors, flooring, interior and furniture materials, and many other applications.

However, it is important to note that the production and use of PVC can also pose environmental and public health concerns, and the use and handling of PVC should be done carefully to minimize negative impacts on the environment and human health.

Typically, products made from PVC can be seen in various colors, although its natural color is often white or transparent. The color variation in PVC products is achieved by blending different additives.

History of PVC

PVC plastic is widely used today, and if you observe your surroundings, you can see many objects made of PVC. So, have you ever wondered: When was PVC discovered? Who discovered it?

To answer these questions, I have found that the development of PVC can be traced through the following stages:

- 1872: Eugen Baumann, a German chemist, first created PVC by chlorinating vinyl chloride. However, this discovery was not commercially developed at that time.

- 1912: Professor Friedrich Klatte, another German chemist, developed a PVC production process for various applications, including water pipes and other products.

- 1920s: Companies such as Bayer and Borden continued researching and developing PVC production methods. The technology for producing PVC improved, and the cost of production significantly decreased.

- 1950: The rapid growth of the industry created a high demand for PVC. PVC production technology was further improved and widely applied in industries such as manufacturing, construction, household goods, and toys.

Until now, PVC remains one of the most common types of plastics worldwide. The production technology has been developed and improved, resulting in PVC with diverse characteristics and applications, ranging from water and electrical pipes to thermal insulation coatings, packaging, flooring, gas conduits, and many other applications.

Properties of PVC

Physical Properties

The physical properties of PVC depend on the composition and percentage of the materials used to manufacture that type of plastic. When there are slight changes in the ingredient composition, PVC will exhibit changes in its properties. However, it still possesses the following characteristic properties:

- Hardness: The hardness of PVC is measured using the Shore hardness or Rockwell hardness scale. The hardness varies depending on the specific material to suit different working conditions. The hardness of PVC is generally lower than that of many alloys, including brass, aluminum alloys, and steel.

- Flexibility: The flexibility of the material is achieved by adding certain additives to the composition. The flexibility of PVC makes it more pliable in specific working conditions.

- Density: The density of PVC typically ranges from 1.3 g/cm3 to 1.45 g/cm3, depending on the formulation of raw materials and the production process.

- Melting Point: The melting point of PVC typically ranges from 100°C to 200°C, depending on the composition and purity of the plastic.

- UV Resistance: PVC has the ability to resist the impact of ultraviolet (UV) rays. However, UV stabilizers may be used to enhance the UV resistance of the plastic.

- Dimensional Stability: PVC exhibits relatively good dimensional stability, meaning the overall size of the product will not undergo significant changes within a certain temperature range.

- Electrical and Thermal Conductivity: PVC is non-conductive and has good thermal insulation properties, making it suitable for insulation and thermal applications.

Chemical Properties

Similar to physical properties, the chemical properties of PVC also vary based on the composition and blending ratios of the raw materials.

- Chemical Resistance: PVC has the ability to resist corrosion and withstand various chemicals. It exhibits high resistance when in contact with acids, alkalis, oils, fats, and common solvents.

- Oxidation Resistance: PVC has good oxidation resistance, preventing the oxidation process from occurring, thereby prolonging the service life of products made from this material.

- Solubility: PVC is insoluble in water, giving it waterproof characteristics. However, it can be dissolved in certain organic solvents such as acetone, cyclohexane, toluene, and other organic substances. Therefore, caution should be exercised to prevent contact with such fluids during use.

Advantages and Disadvantages of PVC

Advantages

Durability: PVC has excellent impact resistance and strength, making products durable and reliable.

Versatile Applications: PVC has a wide range of applications in various industries, including construction, automotive, medical, toys, and many others.

Waterproof Properties: PVC is water-resistant and has good waterproof capabilities, making it an ideal material for applications involving liquids.

Easy Processing: PVC is easily processed and can be cut, welded, molded, extruded, and flexibly bent, allowing for the production of diverse shapes and sizes of products.

Chemical Resistance: PVC has good chemical resistance, especially in acid and alkali environments.

Disadvantages

- Environmental Impact: The production, use, and disposal of PVC can have negative environmental impacts, including the release of toxic substances and difficulties in degradation.

- Additives: PVC production often involves the use of additives such as phthalates and flame retardants, which may raise safety concerns and have health implications.

- Hardness: PVC naturally has a relatively high hardness, which can be a limitation in applications that require high elasticity or softness.

- Flexibility: PVC has moderate flexibility, but it requires the use of plasticizers to soften and enhance elasticity. Excessive use of plasticizers can lead to changes in the properties and flexibility of PVC.

- Flammability: PVC is not inherently flame-resistant and has the potential to ignite. This requires the use of flame retardants or appropriate fire protection measures to ensure safety.

Applications of PVC

PVC plastic is used in various systems and specific working conditions. Since its discovery, it has been widely applied in numerous different fields and plays an irreplaceable role in many specific tasks.

Some applications of PVC include:

- Pipes and tubing systems: PVC is extensively used in the production of water pipes, drainage pipes, gas conduits, PVC butterfly valves, various types of connecting accessories, etc. The durability, flexibility, and corrosion resistance of PVC make it an ideal material for these applications.

- Building materials: PVC is used in the construction industry for manufacturing furniture, partition panels, ceiling coverings, decorative items, etc. These applications are made possible by the material’s flexibility, durability, and ease of processing.

- Automotive industry: PVC is utilized in the automotive industry to produce components such as fuel conduits, lamp housings, soundproofing and insulation parts, bearings, and other components. PVC can withstand harsh conditions and can be processed into various shapes.

The examples mentioned above are just a few instances of PVC plastic applications. In reality, PVC is used diversely and finds its presence in numerous other industries.

For more information on stainless steel materials, please visit stainless steel.