Stainless steel

Stainless steel, also known as inox, is the term used to refer to a type of material that is widely used in both industrial and everyday life due to its outstanding properties:

- Chemical corrosion resistance

- Good strength and temperature resistance

- High durability,…

If you want to learn more about stainless steel, this article can provide you with useful information.

What is stainless steel?

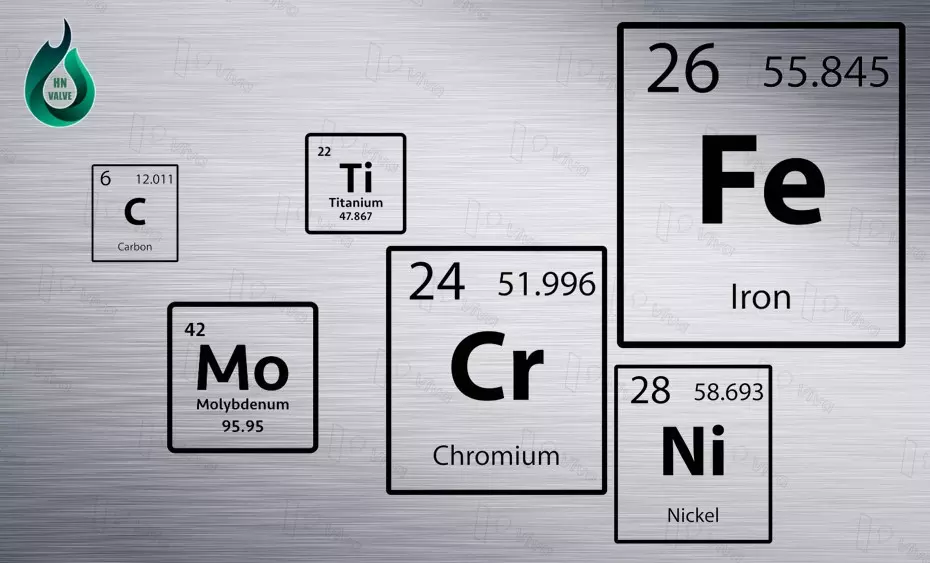

Stainless steel is an iron-chromium alloy with chromium content usually above 10.5%. It can also include other elements such as nickel, molybdenum, titanium, and different components depending on specific applications.

The variation in the metal composition as well as the percentage of each component will create different types of stainless steel, and naturally, their properties will also differ.

The term “stainless” originates from the corrosion resistance and oxidation resistance of this material (in Vietnam, the phenomenon of metal oxidation under normal conditions is referred to as “rust”). The English term for stainless steel is “stainless steel.”

Therefore, based on the characteristics of this material, it is commonly referred to as stainless steel, both to distinguish it from ordinary steel (carbon steel) and to highlight its durability against certain chemicals and metal oxidation.

Stainless steel has the ability to resist corrosion and oxidation, preventing damage from humid environments or chemicals. This makes it an ideal material for various applications, including the production of consumer and industrial products, medical equipment, and many other applications.

Stainless steel has elasticity and can withstand high temperatures, making it suitable for various working conditions.

However, it is more expensive than conventional steel types, and the machining and welding processes can be more challenging. This leads to higher costs for products made from stainless steel compared to the majority of products made from ordinary carbon steel.

Main Components of Stainless Steel

The composition of stainless steel can vary depending on the specific type. For many grades of stainless steel, the basic components typically include the following elements:

- Chromium (Cr): It is the main component of stainless steel, second only to iron in terms of proportion. Chromium plays a crucial role in providing corrosion resistance. The chromium content is usually above 10.5%.

- Nickel (Ni): It is added to enhance corrosion resistance and increase durability. The nickel content can range from approximately 8% to 25%.

- Carbon (C): The carbon content in stainless steel is usually very low, typically below 0.08%. The presence of carbon helps enhance the hardness and strength of the steel.

- Molybdenum (Mo): This component is often added to stainless steel to improve corrosion resistance in more corrosive environments and increase durability.

- Titanium (Ti): Some types of stainless steel contain titanium to enhance corrosion resistance and improve load-bearing capacity.

- Iron (Fe): It is the main component of steel in general and provides overall hardness and durability to the material.

Other elements such as copper (Cu), silicon (Si), manganese (Mn), and various other elements can also be found in stainless steel alloys, depending on specific applications. The main components of stainless steel are adjusted to create specific properties such as corrosion resistance, weldability, hardness, and durability.

How is Stainless Steel Classified?

Stainless steel is classified based on its crystal structure, chemical composition, and physical properties. There are three main types of stainless steel: Austenitic, Ferritic, and Martensitic.

Austenitic

Austenitic stainless steel is the most common and widely used type. It contains 16-26% chromium and 6-22% nickel, along with small amounts of other elements such as manganese, silicon, and copper. Austenitic stainless steel has an austenite crystal structure, which gives it ductility, easy formability, and good weldability. This type of stainless steel is commonly used in the food industry, medical field, construction, and household applications.

Ferritic

Ferritic stainless steel contains 10-30% chromium and usually does not contain or only contains a very small amount of nickel. It has a ferrite crystal structure and exhibits properties ranging from ductile to harder than Austenitic steel. Ferritic stainless steel has good corrosion resistance, making it commonly used in industries such as chemical, petroleum, and automotive.

Martensitic

Martensitic stainless steel contains 11-18% chromium and has a high carbon content. It has a martensite crystal structure, which provides hardness and ease of machining. Martensitic stainless steel is often used in applications requiring high hardness, such as knives, cutting blades, and machine components.

Commonly Used Grades of Stainless Steel

Above, we discussed the main types of stainless steel, and within each main type, they are further classified into smaller material grades. Now, let’s explore the popular metal grades currently in use:

Inox 304 (Stainless Steel 304)

Stainless Steel 304, also known as Inox 304, contains approximately 18% chromium and 8% nickel. It is the most common and widely used stainless steel grade in many industries. Apart from being used to manufacture machine parts, Stainless Steel 304 is also used in the production of everyday items such as spoons, forks, and pots.

Inox 316 (Stainless Steel 316)

Inox 316 has the same chemical composition as Stainless Steel 304 but with an additional 2-3% molybdenum. This provides better corrosion resistance in acidic and salty environments. Stainless Steel 316 is commonly used in applications that require high corrosion resistance, such as the chemical and pharmaceutical industries.

Inox 316L (Stainless Steel 316L)

Stainless Steel 316L is a type of stainless steel in the Austenitic family. The 316L steel grade has a chemical composition similar to Inox 316 but with lower carbon (C) content. The “L” in 316L stands for “Low Carbon.”

Stainless Steel 316L mainly consists of approximately 16-18% chromium (Cr), 10-14% nickel (Ni), 2-3% molybdenum (Mo), and trace amounts of other elements such as silicon (Si), manganese (Mn), phosphorus (P), sulfur (S), etc. The low carbon content in 316L steel helps reduce the formation of carbon compounds (carbides) during processing and welding, improving the corrosion resistance and weldability of the steel.

This material is widely used in industries such as chemicals, pharmaceuticals, food and beverages, medical, construction, household, and many other fields. It is known for its good corrosion resistance, resistance to acids and alkalis, mechanical strength, and oxidation resistance.

Inox 410 (Stainless Steel 410)

Inox 410 contains approximately 11-13% chromium and has a high carbon content. It has hardness and can withstand high temperatures. Stainless Steel 410 is commonly used in the production of knives, bearings, and other machine parts.

Inox 2205 (Stainless Steel 2205)

AISI 2205 is a type of duplex stainless steel that combines Austenitic and Ferritic structures. It contains approximately 22% chromium and 5% nickel, along with small amounts of elements such as molybdenum and copper. Stainless Steel 2205 exhibits excellent corrosion resistance and mechanical strength, making it commonly used in high-pressure industrial applications, such as the oil and gas industry.

Applications of Stainless Steel

Derived from the material’s properties such as high strength, chemical corrosion resistance, pressure and high-temperature resistance, stainless steel has been applied in various fields since it was discovered by an English engineer named Harry Brearley in 1913.

Since then, it has been used in many different areas, and over time, researchers have developed new types of stainless steel with specific properties suitable for various working conditions.

Some examples of the application capabilities of stainless steel include:

- Piping equipment: Stainless steel is commonly used to manufacture various types of equipment and accessories related to piping. Its ability to resist oxidation while continuously being exposed to various flowing substances, along with its strength and heat resistance, makes it the perfect choice for producing devices such as valves, pipes, and connecting fittings. Some types of valves made from stainless steel include ball valves, butterfly valves, and check valves.

- Medical and pharmaceutical industries: Stainless steel is highly valued for its safety, as it does not generate chemical reactions with many types of fluids. It is used in the production of food, pharmaceuticals, and various chemicals. Stainless Steel 316L is commonly used as a material for manufacturing equipment in the microbiological system.

- Household appliance manufacturing: Stainless steel is used to manufacture various household items, including kitchen utensils such as pots, knives, and spoons. With its durability and oxidation resistance, stainless steel is used as a material for manufacturing bathroom equipment, including bathtubs, showers, faucets, and various frame structures. Additionally, many other household products and decorations are made from stainless steel.

- Aerospace and maritime industries: Stainless steel is used in the aerospace and maritime sectors to produce aircraft components, ships, storage tanks, pipelines, valves, nozzles, and other devices. It has corrosion resistance in marine environments and high-temperature environments.

In addition, stainless steel has many applications in the automotive industry, electronics industry, renewable energy industry, water industry, and more.

Conclusion

In this article, we have learned about stainless steel, its important properties, different types, application capabilities, and various related aspects of stainless steel materials.

I hope that this article has provided you with an overview of stainless steel and answered your questions. As always, I am available to answer any questions and welcome feedback from readers to provide more accurate and useful information in the future. Thank you for reading the article!