Teflon (PTFE)

Teflon is a familiar term for those working in the fields of mechanical engineering, machinery, and materials. So, what is Teflon? What are its properties? And what is it used for? Let’s explore these questions in today’s article.

What is Teflon?

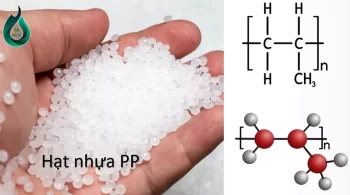

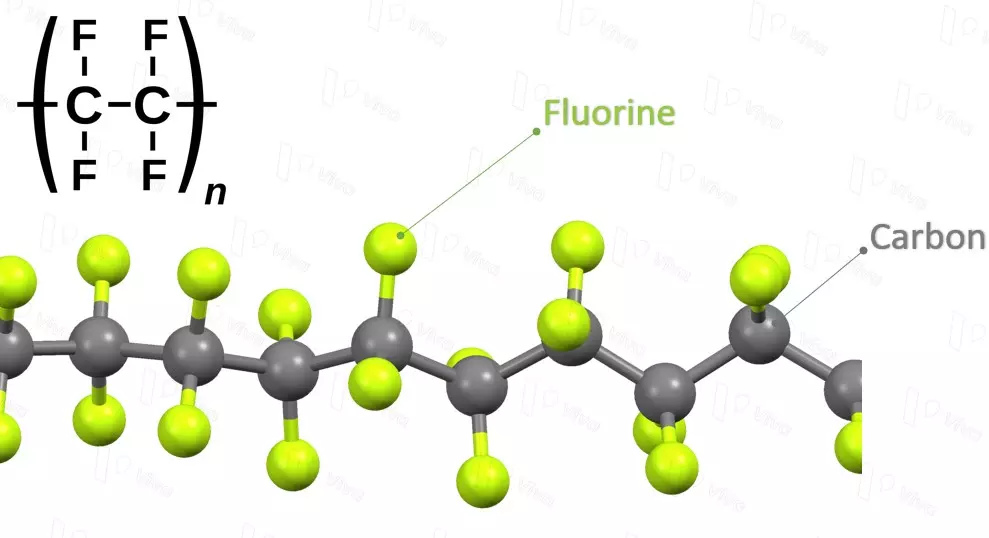

Teflon is a commonly used term in Vietnam and some other countries to refer to PTFE (Polytetrafluoroethylene), a type of fluoropolymer polymer with a structure formed by a chain of fluorene molecules linked to carbon and fluorine atoms.

Some notable properties of PTFE material include:

- Chemical inertness: This allows it to be used in various devices that handle chemicals and applications related to non-stick coatings.

- Flexibility: PTFE is quite flexible and has elasticity, making it suitable for manufacturing gaskets and seals.

- High-temperature resistance: Compared to many other materials, Teflon can withstand relatively high temperatures, with a working temperature limit of around 250°C.

In Vietnam, this type of material is referred to by various names, such as:

-

- Teflon resin

- PTFE resin

- Teflon or PTFE.

In reality, Teflon is a well-known brand of non-stick coatings used in numerous industrial and household applications. Teflon is also commonly known as polytetrafluoroethylene (PTFE), an inorganic fluoropolymer polymer.

Chemical Formula of PTFE

The chemical formula of PTFE is (C2F4)n, where “n” represents the number of repeating units in the PTFE molecule. PTFE stands for PolyTetraFluoroEthylene, a non-branched polymer formed by the combination of ethylene units (C2H4) entirely substituted with fluorine atoms (F).

The detailed formula of a single PTFE unit is represented as follows: (C2F4).

When multiple PTFE units are linked together through C-C bonds, we have the general formula of PTFE: (C2F4)n.

Development History of PTFE Material

Polytetrafluoroethylene (PTFE) is a type of material with very special properties, applied in various fields. Below is a summary of the development history of PTFE:

- 1938: PTFE was accidentally discovered by Roy Plunkett, a chemist at DuPont, a chemical company. He discovered this material while experimenting with fluorocarbon gas compounds. A small amount of tetrafluoroethylene gas spontaneously polymerized inside a metal tube at high temperatures, creating a thin film of this non-stick material. DuPont then named this newly discovered material “Teflon.”

- 1940: DuPont began researching and developing applications for Teflon, but industrial production of PTFE encountered many difficulties. In 1945, DuPont started commercial production of PTFE under the brand name Teflon.

- 1950: The first commercial applications of PTFE began to appear, including its use in the chemical, mechanical, and medical industries. PTFE was favored for its heat resistance, non-stick properties, chemical resistance, and electrical insulation.

- 1960: The application of PTFE expanded to consumer products, being used for familiar materials in daily life, such as non-stick coatings for pans, electrical insulation and insulation for some household appliances, and many parts and components of automobiles.

- 1990: New developments in PTFE processing technology made the production and use of this material more efficient and diverse. New applications of PTFE emerged in electronics, medical, aerospace, and the petroleum industry.

- Present: PTFE continues to be widely used and is one of the most influential polymers in history. It is applied in various fields such as industry, medicine, household products, automotive, aerospace, electronics, and many other technical applications. Many different companies have developed variations of PTFE to meet the diverse needs of various industries.

Characteristics of Teflon

After a long period of application and development, PTFE (Teflon) is now available in many variations, but the basic characteristics are typically limited to the following ranges:

- Melting temperature: 317 ~ 337°C

- Operating temperature: 260°C

- Elongation at break: 300~500%

- Density: 2.1 ~ 2.3 g/cm³

- Electrical conductivity: Good insulator

- Non-stick property: Excellent

- Chemical resistance: Capable of resisting various chemicals (almost all common chemicals).

- Surface friction: Very low due to its non-stick properties

Current Teflon Plastic Products on the Market

Teflon is a type of material used to manufacture parts and components of machinery and equipment, used in construction, or applied as coatings on surfaces of some tools, etc.

In addition to finished products, there are components made from Teflon or products entirely made from Teflon available on the market. These materials come in various shapes and sizes to facilitate production processes.

Teflon Sheets

Regarding Teflon in sheet form, the product is available in various sizes. Often, pre-cut square sheets with edges measuring 1 meter are commonly seen. Their thickness can also vary, ranging from 1mm to several centimeters or even thicker.

Thin Teflon sheets are usually rolled up to save space, while thicker ones are kept flat.

Teflon sheets are commonly used for shielding purposes, some construction applications, or they can be processed and cut to create special shapes to serve various purposes.

Teflon Film

Teflon film is essentially Teflon in sheet form but much thinner, hence it is also called a film. These products are commonly available in the market with thickness ranging from 0.01mm to 1mm, provided in rolls of various sizes.

They are often used for shielding purposes in manufacturing, used as partition curtains between areas, utilized to manufacture adhesive tapes, used as wrapping films, and employed in construction applications.

Teflon Rod

Teflon rods are commonly found in mechanical processing factories, where they are placed into lathes to create components used in machinery.

Teflon rods are supplied in round or square shapes, with various sizes:

- Round Teflon rods: Diameter 8, diameter 10, diameter 15, diameter 20, etc.

- Square Teflon rods: Products with square cross-sections, with edges measuring 2cm, 3cm, 4cm, 5cm, etc.

The length of each rod ranges from 3 to 6 meters or longer, depending on the supplying unit.

Teflon Tubing

Like other plastic Teflon products, Teflon tubing is also available in various size options. Teflon tubing has a cross-sectional shape resembling a cloth ring.

The dimensions of Teflon tubing, including length, diameter, and wall thickness, can vary greatly.

Depending on the size of the Teflon tubing, it can be used as conduits for various fluids (both liquid and gas), and can be machined into special shapes to create gaskets and seals, among other applications.

Practical Applications of Teflon

PTFE plastic, also known by its trade name Teflon, has wide-ranging practical applications thanks to its unique mechanical and chemical properties. Below are some real-world applications of this type of material:

- Liquid Conduits: Due to its excellent chemical resistance, Teflon is used in manufacturing chemical liquid conduits, oil pipelines, water pipes, etc. It helps to avoid the impact of chemicals, ensuring safety when transporting various types of liquids.

- Industrial Valves: With characteristics such as elasticity, heat resistance, and low friction, this material is used to create gaskets for various industrial valves, including ball valves, butterfly valves, globe valves, etc.

- Medical Applications: Teflon is used in medical applications such as non-stick medical parts and instruments, and non-stick surfaces in medical devices.

- Food Industry Applications: It is used to create non-stick surfaces for pots, pans, ovens, and other cooking appliances. This helps to reduce the use of oils and fats and makes cleaning easier.

- High-Temperature Resistant Parts: Due to its ability to withstand high temperatures up to 260°C, it is used to make parts in high-temperature applications such as fuel lines, bearing protection rings, etc.

These applications are just some examples of how Teflon is used in everyday life and in various industries. Its diverse properties have made it an important material in many fields.