What is an electromagnetic water flow meter

What is an electromagnetic water flow meter?

An electromagnetic water flow meter, in practice, is a type of electromagnetic flow meter. This type of flow meter is not only used to measure regular water flow but also to measure the flow of various other fluids, including water, wastewater, chemicals, etc. The condition for using this flow meter is that the fluid being measured must be conductive. Therefore, an electromagnetic flow meter cannot be used to measure the flow of distilled water, gases, and insulating oils.

The device operates based on the phenomenon of electromagnetic induction. It uses a pair of electromagnets to generate a magnetic field inside the pipe. When the conductive fluid flows through this pipe, it acts as a moving conductor, and an electric current is induced within the fluid due to the magnetic field created by the electromagnets.

By measuring the voltage of this electric current, one can determine the velocity of the fluid flow inside the pipe.

With this measurement method, the device does not cause disturbance to the flow nor significant pressure loss during the measurement process.

Except for distilled water, an electromagnetic water flow meter provides an optimal solution for measuring the flow rate of various liquid substances, including water, clean water, and chemicals.

History of the Formation of Electromagnetic Water Flow Meters

The premise for the emergence of electromagnetic water flow meters is Faraday’s law, which can be understood as follows:

- When a moving electric conductor is placed perpendicular to the varying magnetic field lines inside a magnetic field, an electromotive force will be induced within the conductor. This electromotive force is directly proportional to the velocity of the conductor’s movement. Michael Faraday discovered this law in 1831.

- Around the 1950s, the first electromagnetic water flow meter was developed. However, this device was not widely used until the 1970s when flow meters started to be commonly used in water supply and wastewater treatment systems.

- Over the years, these devices have been continuously improved, incorporating advances in materials and processing speed of microchips. This has helped enhance accuracy and improve their applicability, especially for corrosive fluids.

Currently, electromagnetic water flow meters are manufactured and extensively used worldwide in industrial applications, water supply systems, and wastewater treatment. They are among the most efficient and reliable liquid flow measuring devices available on the market.

Structure and Operating Principle of Electromagnetic Water Flow Meters

Structure of Electromagnetic Water Flow Meters

The water flow meter with electricity measurement is a combination of multiple components and details, including electronic components and mechanical parts. Basically, the device can be considered as being composed of four main parts, including:

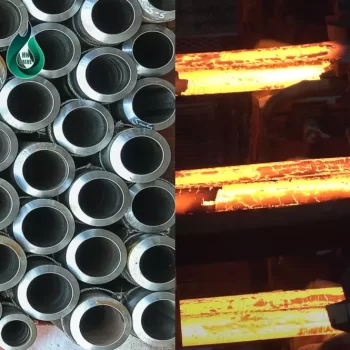

- Meter body: The body of the electromagnetic water flow meter is a metal tube with a circular cross-section, which can be made of steel or stainless steel. Devices made from steel bodies are often coated with an epoxy layer by the manufacturer to enhance corrosion resistance. The inner lining of the meter is usually coated with plastic or ceramic to limit electrical contact with the meter body, which could cause interference.

- Electromagnets: This component consists of two copper coils placed opposite each other outside the pipe wall. Its function is to create a magnetic field inside the pipe.

- Electrical contacts: Electrical contacts or electrodes are the components that come into direct contact with the liquid to be measured. Their task is to measure the electromotive force generated within the liquid as it flows in the electric field created inside the pipe. The number of electrodes used is usually even, with corresponding quantities of 2, 4, 6, etc. They are arranged symmetrically, and the larger the diameter of the meter body, the more electrodes are used.

- Processing and display unit: This component includes electronic circuits, a display screen, and adjustment buttons. They are combined to perform functions such as calculation and display of measured values.

Principle of Operation of Electromagnetic Water Flow Meter

As introduced in the beginning of the article, the electromagnetic water flow meter operates based on the principle of electromagnetic induction, discovered by the British physicist Michael Faraday. Applying this principle to the design and construction of the electromagnetic water flow meter, the basic principle of operation of the device is as follows:

The conductive fluid flows through the pipe system and enters the body of the flow meter (with a diameter of D). Two electrical coils are arranged outside the body of the meter, and when power is supplied, they generate a magnetic field inside the pipe with a density of B. This magnetic field induces an electromotive force (E) in the flowing fluid, which is proportional to the fluid velocity (V).

The relationship can be expressed by the following formula:

E = B × D × V.

The electromotive force (E) is measured through electrodes placed around the pipe walls, with D being the fixed diameter of the flow meter body. The coefficient B is pre-adjusted and set along with the calculation equations. Therefore, using the pre-loaded equations and coefficients during the design process, the flow velocity value is calculated and displayed on the screen of the electromagnetic water flow meter.

Installation Notes for Electromagnetic Water Flow Meter

Based on the working principle, structure, and function of the electromagnetic water flow meter, in order to ensure accurate measurements, besides understanding the technical specifications and working characteristics of the system, the working procedure of the flow meter plays a crucial role. Here are some installation notes for the electromagnetic water flow meter to ensure effective, reliable, and highly accurate measurements.

The installation position of the device needs to ensure a stable flow rate. The fluid entering the body of the flow meter needs to be completely filled to ensure that the electrodes are always in direct contact with the measured fluid.

The electromagnetic flow meter for measuring water flow needs to be grounded during installation. This is done to fulfill certain requirements:

Safety: Grounding allows the electrical current to be directly transmitted to the ground, instead of being transmitted through the water flow to other devices in the system, especially for 220V electrical metering devices.

Noise reduction: Grounding helps reduce electromagnetic interference, as well as wave interference. These factors directly affect the accuracy of the device’s measurements.

Practical applications of electromagnetic water flow meter

The electromagnetic water flow meter is a measuring device that uses Faraday’s law to measure the flow of water through pipes. It is considered a highly accurate type of water flow meter, with a special operating principle. The device is suitable for measuring various types of fluids.

The translation of the given text into English, keeping the HTML code intact, is as follows:

The application of electromagnetic water flow meters is very popular in industrial, commercial, and domestic applications. Here are some specific applications:

- Water treatment industry: Used to measure the flow rate of water through water treatment systems, including wastewater treatment and clean water treatment systems.

- Hydropower applications: In hydropower plants, water is used to rotate turbine generators. To ensure efficient control of the water flow and for various purposes, it is crucial to know the flow rate inside the system.

- Agricultural production activities: Water flow meters are used in water supply and drainage systems for irrigation, crop cultivation, and aquaculture. By using flow meters, we can better manage the efficient use of water resources.

In general, electromagnetic water flow meters have numerous practical applications in production, accurately and reliably measuring the flow rate through pipelines. They assist users in evaluating systems and optimizing water resource utilization.