Pressure switch

Giá gốc là: 200.000 ₫.160.000 ₫Giá hiện tại là: 160.000 ₫.

Cập nhật lần cuối ngày 11/04/2025 lúc 09:05 sáng

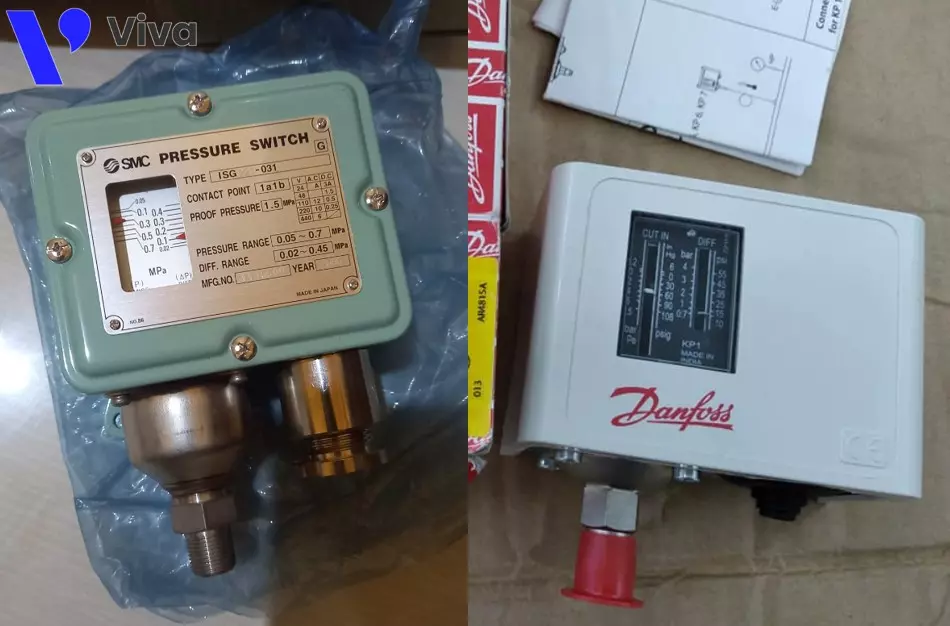

Pressure switch or pressure relay are both common names for a device called “Công tắc áp suất” in Vietnamese. They are widely used in many applications, especially in industrial applications.

In today’s article, let’s explore the relevant information about pressure relays with VIVA: Construction, operation, functions, applications, etc.

Understanding pressure switches

A pressure switch is a device that functions to activate or deactivate an electrical circuit based on signals related to changes in pressure in a particular system, typically a pneumatic or hydraulic system. They can be mechanical or electronic devices, depending on the construction and operating principles of the device itself.

There are two main types of pressure switches: positive pressure switches and negative pressure switches. Positive pressure switches are designed to activate the electrical circuit when the pressure exceeds a predetermined threshold. On the other hand, negative pressure switches are activated when the pressure drops below a certain threshold.

Like conventional switches, this device is used primarily to turn on or off electrical machinery or equipment. However, instead of directly manually switching on or off, pressure relays automatically turn on or off based on changes in the supplied pressure. This is why pressure relays are used in systems and also serve the purpose of protecting the equipment in certain circumstances.

Structure and operation of pressure switches

Basic structure

In reality, there are various types of pressure switches that have been and are being used, and the structure of these devices will have certain differences.

Here is the basic structure of a pressure relay:

- Terminal connections: For the basic device we are referring to here, they have a simple structure, so there are 2 terminal connections (one for connecting to the power source, and the other for connecting to the device to be turned on/off). In reality, the number of terminal connections of a relay can vary depending on the type.

- Adjustment screw: This detail has the function of adjusting the opening and closing pressure level of the pressure switch.

- Electrical contacts: The electrical contacts are made of materials with good conductivity. They are the main components that affect the opening and closing operations of the pressure switch. This open/close state will change when the pressure inside the system exceeds the set threshold.

- Pressure diaphragm: This component has two main functions, which include separating the electrical contacts from the fluid and amplifying the force exerted by the pressure of the system on the device.

- Spring: The spring’s elastic force acts to eliminate the force formed by the pressure of the system, aiming to maintain a stable working state within a certain pressure range.

- Shaft: This detail is responsible for stabilizing the motion and transmitting the motion to the electrical contact component.

Operation of pressure switches

Basically, the operation of a pressure switch is based on the differential force, which comes from two sides. One part is the force exerted by the spring, and the other part is the force exerted by the pressure of the compressed air on the diaphragm. These two forces have the same direction but opposite directions to each other.

The spring’s elastic force can be considered constant during one operating cycle. The value that changes here is usually the pressure of the system, which is used by the pressure switch.

When the pressure applied to the device changes, as the pressure increases, a force is generated due to the increasing pressure, until a certain threshold where this force overcomes the force exerted by the spring.

The pressure switch will change its working state, which is to open the circuit and prevent the current from flowing (for a positive pressure switch), whereas for a negative pressure switch, this process will be reversed.

Features of pressure switches

Basically, a pressure relay has a basic function, similar to a regular electrical switch, which is to turn on or off a certain circuit. However, due to its special design, it has additional functions, including:

- Automatic on/off: The device operates based on the changes in system pressure, allowing it to function independently.

- Ability to adjust the working pressure limit: On the body of pressure sensing devices, there is an adjustment screw to set the opening and closing pressure limits of the device. When this detail is adjusted, it loosens or tightens the spring, thereby changing the spring’s elastic force. As a result, the working state of the pressure switch changes along with the adjusted pressure limits.

- System protection: With the ability to automatically cut off the power supply to the device when a certain pressure limit is reached, the pressure switch can be set to the system’s pressure limit. At this point, when the system pressure reaches the pre-set limit, the device will cut off the power supply to maintain the operation of pumps, compressors, etc. (depending on the system).

Common failures of pressure switches

Pressure switches are devices that are considered to have a relatively high durability. Under ideal working conditions, these devices can work continuously for many years.

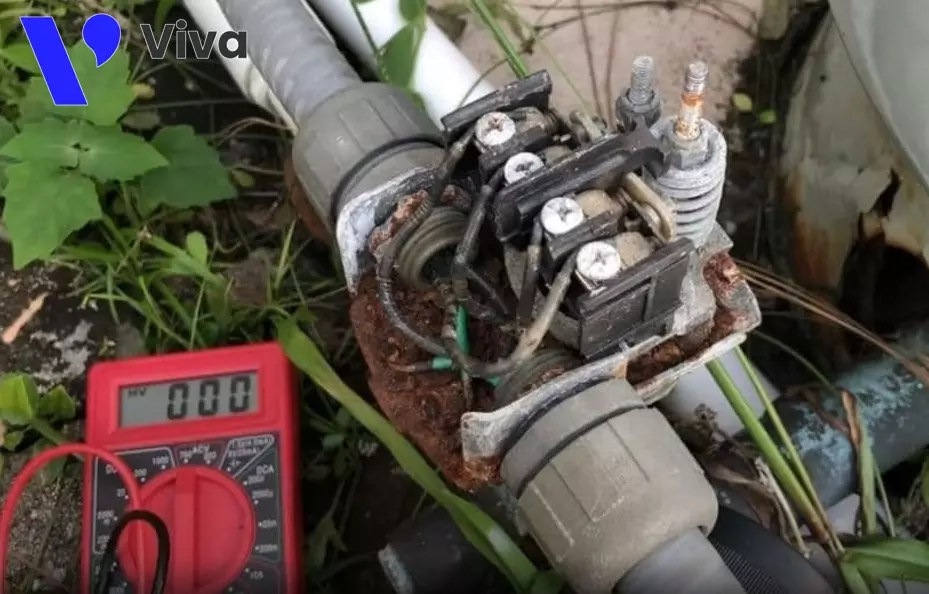

However, in practical applications, these devices are not always used under ideal conditions. Most pressure switches are often used in harsh working conditions. This leads to various failure situations that can be addressed if the causes are known.

The common failures of pressure switches include:

- Contact burning: The cause of contact burning is usually due to excessive or insufficient current, or dust between the contacts causing electrical resistance. Over time, more heat is generated, leading to contact burnout.

- Fluid leakage: Depending on the type of sensing switch used in the system, the type of leaked fluid can vary (compressed air, hydraulic oil, or water). The causes of this phenomenon may include prolonged use of the device in the system, leading to aging of the sealing diaphragm or excessive wear of the piston.

- Switch jamming: This is a common issue with mechanical pressure switches operating in dusty and high humidity conditions. Over time, moisture and dust accumulate and adhere to the internal components, causing mechanical obstructions.

- Electronic component failure: For electronic pressure switch models composed of various electronic components, these components are susceptible to environmental factors such as temperature and humidity. Therefore, under unfavorable conditions, failures can occur.

Practical Applications of Pressure Switches

Derived from the useful features that pressure switches offer, combined with the diverse range of product variations, they are applied in numerous systems where pressure plays a crucial role.

Here are some practical examples of pressure switch applications:

Compressed Air Systems

In compressed air systems, these devices are often installed directly on air compressors, specifically on the air tanks. When the pressure of the compressed air in the tank reaches a predetermined level, the pressure switch interrupts the electrical circuit, thereby stopping the operation of the air compressor.

Water Pump Systems

Similar to air compressors, pressure relays are connected to the power supply line of water pumps, and the pressure sensor is attached to the water pipe at the bottom of the tank. As the amount of pumped water increases, the water pressure exerted on the pressure switch also increases. Applying this principle, pressure switches are commonly used to control the power supply to water pumps.

Hydraulic Systems

For oil pump systems used to operate various hydraulic devices, pressure relay are employed to ensure that the hydraulic pressure inside the system never exceeds the predetermined safety limits.

See more products vacuum foot valves.

Đánh giá

Chưa có đánh giá nào.