Stainless steel ball valve products

Giá gốc là: 230.000 ₫.130.000 ₫Giá hiện tại là: 130.000 ₫.

Cập nhật lần cuối ngày 20/06/2023 lúc 04:12 chiều

Introduction to Stainless Steel Ball Valve Products

Stainless steel ball valves are products made primarily from stainless steel materials. The majority of components and parts of these ball valves are manufactured using materials such as stainless steel 201, stainless steel 304, stainless steel 316, or materials with similar properties to stainless steel, such as CF8 and CF8M steel.

Due to being constructed from materials with excellent mechanical properties, stainless steel ball valves exhibit high hardness and good corrosion resistance.

Currently, stainless steel ball valve products are used and circulated in the Vietnamese market, with the majority of them being imported from abroad. The two countries that have the largest market share in Vietnam are Taiwan and China. Stainless steel ball valves come in various designs and sizes to meet the technical requirements of different systems in various industries.

See more:

In the past, the majority of stainless steel ball valve products were operated manually using handles. However, in recent years, with the strong development of the Vietnamese industry, there has been an increasing demand for stainless steel ball valves to serve in systems that require automatic operation or remote control capability, leading to a significant rise in the use of electrically controlled ball valves and compressed air control.

Structure of Stainless Steel Ball Valve Equipment

Similar to conventional ball valves, stainless steel ball valves consist of two main components: the valve body and the control mechanism.

Structure of the Control Mechanism in Stainless Steel Ball Valve

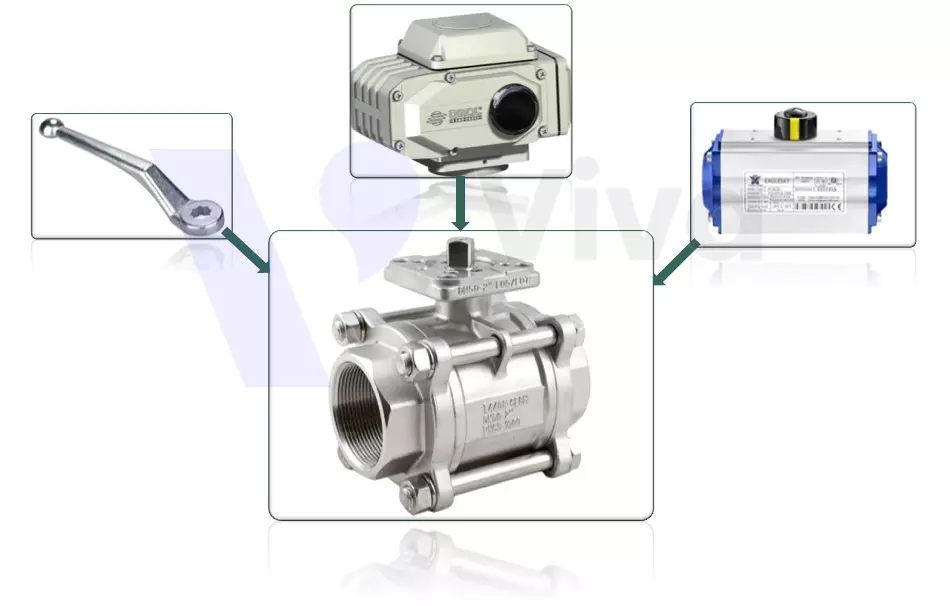

The control mechanism is the part that receives control input from the user. Based on their distinctive operating methods, control mechanisms can be classified into three types: hand lever control, electric control, and pneumatic control.

For hand lever control: This is the traditional and oldest mode of operating valves. It involves attaching a suitable steel rod to the valve shaft, and users rotate the lever to specific positions within the range of 0 to 90 degrees to control the valve’s opening, closing, or throttling operations.

Although electric and pneumatic control mechanisms are available nowadays, hand lever mechanisms are still widely used in stainless steel ball valve products due to their advantages such as affordability, high durability, and easy and quick valve operation.

Electrical control unit: It is a device that uses electrical energy to control the opening and closing operations of a valve. The electrical energy is transformed into mechanical energy through an electric motor, which amplifies torque and reduces rotational speed through a gearbox before transmitting it to the valve shaft.

The valve can be remotely controlled and has the ability to work automatically. It is suitable for installation in large systems with a high number of valves. However, valves of this type have a relatively high cost and lower durability compared to pneumatic and manual control.

Pneumatic control unit: This device operates entirely based on high-pressure compressed air. Pneumatic control units have the advantage of high durability, quick opening and closing operations, and human safety as they do not use electricity. They also have a lower cost compared to electrical control units. However, pneumatic control units require a suitable compressed air system and accompanying control accessories.

Structure of the valve body

In general, all types of ball valves have a similar basic structure for the body, with slight differences in shape or additional details.

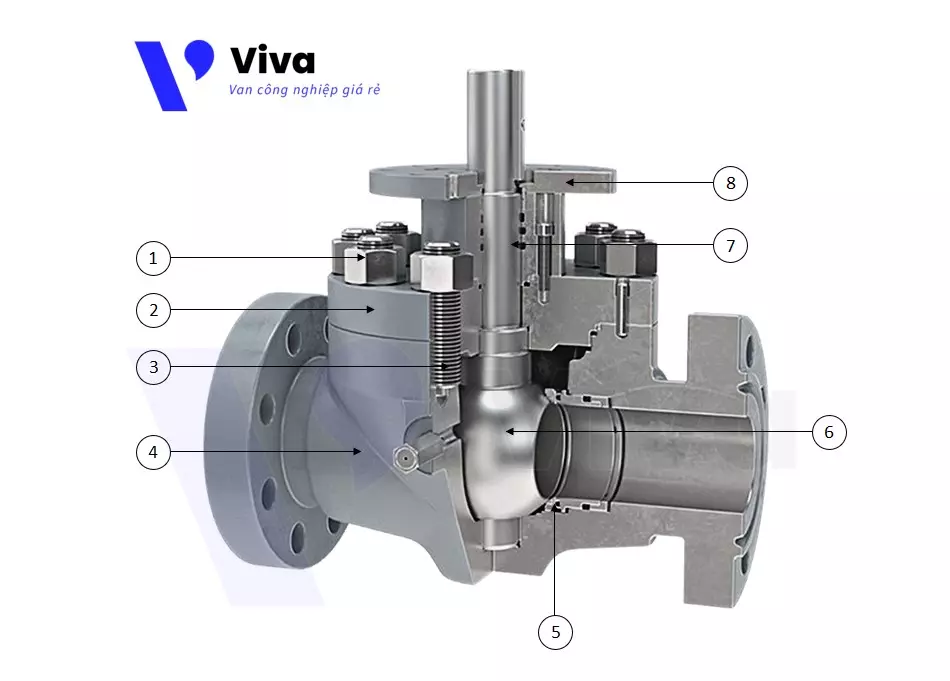

The body of the valve is composed of the following parts:

1 – Screw nut

2 – Valve body cover: As an integral part of the valve body, it is made of the same material as the lower part of the valve, which is stainless steel (inox). The cover is responsible for sealing the valve, fixing and connecting other components of the valve together, especially for electric control ball valves and pneumatic control ball valves. The valve cover is designed with an additional flange to connect the valve body to the control unit.

3 – Insertion screw

4 – Valve body: The ball valve body is responsible for connecting and positioning the components. It is made of stainless steel (inox). The ends of the valve ports are designed with flanges or threaded for easy installation of the valve on pipelines, especially for sanitary ball valves, which are designed with clamp connections.

5 – Sealing gasket: This component supports the sealing of the valve when it is in the closed state. The gasket of the stainless steel ball valve can be made of Teflon or alloy.

6 – Valve ball: A stainless steel ball is designed with a through-hole at its center to allow the fluid to flow through when the valve is in the open state.

7 – Valve stem: The stainless steel ball valve stem receives torque from the control unit to change the opening angle of the valve ball. The valve stem is also made of stainless steel and processed with high precision and surface finish.

8 – Flange for connecting the control unit.

Classification of stainless steel ball valves

As mentioned at the beginning of the article, stainless steel ball valves have a wide variety of types on the Vietnamese market, which can confuse customers when they first approach and seek to purchase stainless steel ball valves. To help customers understand the products and grasp the types of stainless steel ball valves available on the market, we have classified stainless steel ball valves into the following main types.

Classification based on valve body structure

One-piece stainless steel ball valve

This type of valve has a solid valve body. It is the simplest type of ball valve with a very simple structure, fewer components, and stable operation with high durability. It can work in various environments. Since the valve is cast as a solid piece, its components cannot be disassembled.

The one-piece valve is small in size, suitable for threaded installation designs.

Two-piece stainless steel ball valve

With the two-piece stainless steel ball valve, the valve body is composed of two separate parts, which are connected and fixed together through threaded joints or bolts. When cleaning or maintaining, the two halves of the valve body and the components can be disassembled. The two-piece stainless steel ball valve is designed with larger dimensions than the one-piece type and can be installed with both flanged and threaded connections.

Stainless Steel 3-Piece Ball Valve

The stainless steel 3-piece ball valve consists of a valve body formed by two valve ports and a middle body section. These three components are tightly joined together using the tightening force of four bolts located at the four corners, ensuring a strong connection between the parts. Therefore, this type of valve is commonly used in high-pressure and high-temperature systems. It can be installed in various ways, such as threaded connections, flange connections, or direct welding onto pipelines.

Classification based on control mechanism

Stainless Steel Hand Lever Ball Valve

The hand lever ball valve is a type of ball valve that operates manually. Users need to directly manipulate the lever to control the working state of the valve. The lever is usually made of stainless steel, cast iron, or steel, while the remaining parts are mostly made of stainless steel.

Stainless Steel Electrically Controlled Ball Valve

This type of valve is controlled through an electric actuator connected to the valve stem. To operate the electric actuator of the valve, a recommended current specified by the manufacturer needs to be supplied to the control unit. The currents commonly used for control units are DC24V, DC36V, AC220V, AC110V, and so on.

There are two types of actuators used in stainless steel electrically controlled ball valves:

On/Off control actuator: This type of actuator fully opens or closes the valve, and it is cheaper compared to linear control actuator.

Linear control actuator: With linear control, the valve can be operated at different angles, allowing for flow regulation.

Based on the characteristics of these two types of electrically controlled ball valves mentioned above, one can consider the appropriate choice based on the working conditions and technical requirements of the system.

Stainless Steel Pneumatically Controlled Ball Valve

Instead of using an electric actuator, the pneumatically controlled stainless steel ball valve is operated through a pneumatic actuator. Compared to electrically controlled ball valves, pneumatically controlled ones have higher durability, faster opening and closing times, and lower cost.

Classification based on installation method

Threaded stainless steel ball valves

The characteristics of threaded stainless steel ball valves are their small and medium sizes, with threaded connections on both valve ends. Currently, there are many different types of threaded ball valves available on the market.

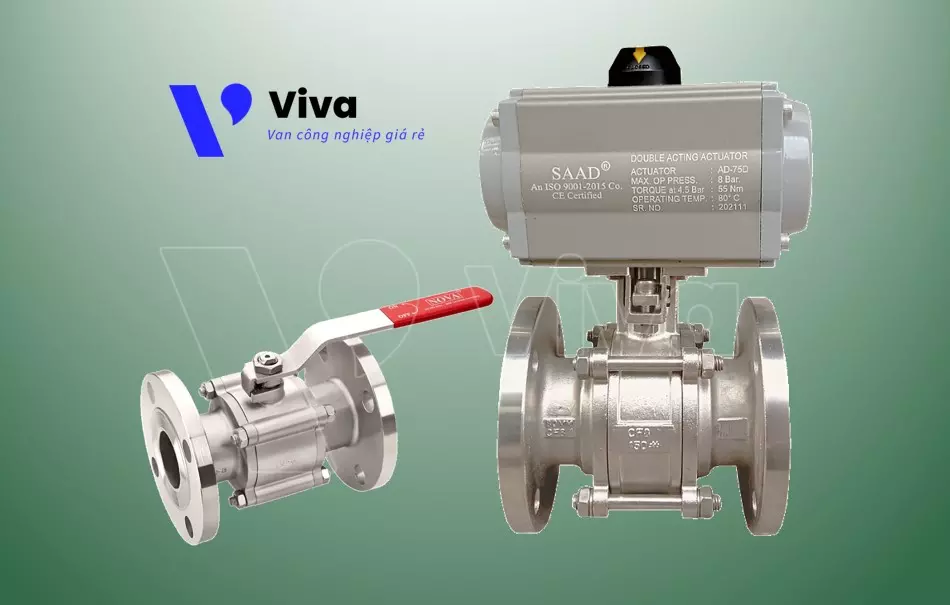

Flanged stainless steel ball valves

Flanged ball valves are designed to withstand high pressure, and the flange face does not have small dimensions. Therefore, stainless steel ball valves with flanged connections are not available in sizes below DN50. The flange face of the ball valve is designed according to installation standards such as JIS, BS, ANSI, etc., suitable for installation in piping systems in Vietnam.

Welded stainless steel ball valves

Welded stainless steel ball valves are directly welded into systems that require high pressure and high temperatures, which cannot be achieved with flanged or threaded connections. However, this installation method is difficult and requires skilled professionals to perform the welding process. The welded joints must be even, secure, and completely leak-proof, and the valve’s alignment with the pipe connections must be concentric.

3-way stainless steel ball valves

3-way stainless steel ball valves are a special variant of conventional ball valves, featuring three ports connected to pipelines, while the valve body is made of stainless steel.

With 3-way ball valves, the products are divided into two different types: T-shaped and L-shaped designs.

In the L-shaped design, the fluid can only flow through two of the three ports at right angles to each other at the same time, or the flow can be completely shut off.

The T-shaped design provides more flexible control, allowing the fluid to flow through all three ports of the valve simultaneously, shutting off any two of the three ports completely.

3-way stainless steel ball valves are suitable for installation at intersecting positions between three pipeline segments of the same size. They are widely used in industrial applications with complex intersecting pipeline systems.

These valves are designed for both flanged and threaded installations. Particularly, the sanitary 3-way stainless steel ball valves are designed with a quick clamp installation method, which will be discussed in detail below.

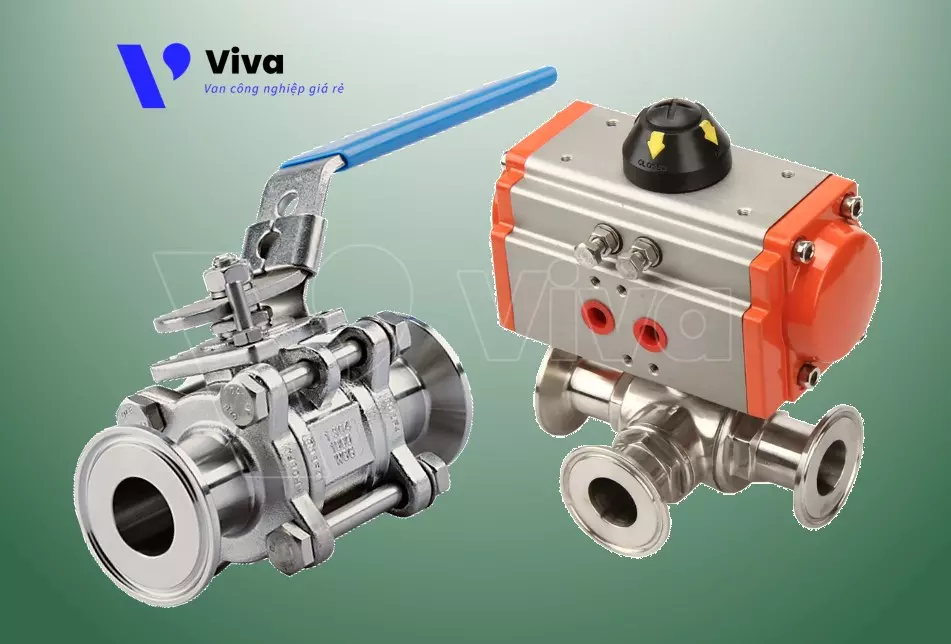

Stainless Steel Sanitary Ball Valve

It is a specialized type of valve designed to work in food or pharmaceutical production lines.

The requirements for this device are that it should not oxidize, have good corrosion resistance, not react chemically with the components present in the food or pharmaceutical products being produced.

The valve must be manufactured with high precision and a smooth surface finish to prevent the production materials from adhering to the inside of the valve. It should also be easy to clean. Another requirement is that the valve installation type must be easy to disassemble and assemble into the system because the valve needs to be regularly removed for overall cleaning.

To meet these requirements, manufacturers have specifically produced the stainless steel sanitary ball valve, using materials such as stainless steel 316, a material known for its high hardness, excellent corrosion resistance, and near inertness to many common chemicals, thus solving the material challenge.

The installation type of the stainless steel sanitary ball valve is a quick clamp connection.

Origin of Stainless Steel Sanitary Ball Valve

Currently, in Vietnam, only a few small-sized stainless steel ball valve products suitable for household use are produced domestically. Industrial-use products, on the other hand, are imported from countries such as China, South Korea, Taiwan, Japan, and some European countries. Among them, products from China and Taiwan currently hold the largest market share due to their advantages of low cost, variety in types, sizes, and segments.

Japanese-branded products, in general, and stainless steel ball valves, in particular, have long gained popularity among Vietnamese users due to their high durability and excellent product finishing. However, Japanese products are relatively expensive, making it economically challenging for many of our customers to access Japanese stainless steel ball valves.

In recent years, the industrial sector in South Korea has experienced strong development, and industrial equipment and machinery serving the industry have been rapidly improved and developed. As a result, Korean-related valve products have penetrated many countries, including meeting the demanding markets of Europe and the United States.

Advantages and Disadvantages of Stainless Steel Sanitary Ball Valve

In any product, advantages and disadvantages always coexist, and the stainless steel sanitary ball valve is no exception. Although it has many advantages, in my personal opinion, this type of valve still has some minor drawbacks. As a customer, I will outline the advantages and disadvantages of this valve so that customers can consider and choose the most suitable products for their needs.

Advantages of Stainless Steel Sanitary Ball Valve

Being made of stainless steel, which is the best material in terms of mechanical properties among the common materials used to manufacture valves, the stainless steel sanitary ball valve undoubtedly has more advantages than other types of ball valves. Some of the advantages include:

- The valve has excellent pressure and temperature resistance, accompanied by good corrosion resistance that many other valve types lack- The use of a ball valve for flow control provides high sealing efficiency.

- The valve can be used for both liquid and gas fluids.

- It operates stably in various working conditions. With stainless steel manual ball valves and stainless steel pneumatic control ball valves, the switching between open and closed states of the ball valve is smooth and quick.

Disadvantages of stainless steel ball valves

Overall, stainless steel ball valves are quite perfect products with many advantages; however, they still have some minor drawbacks.

The weight of stainless steel ball valves is considerable. When compared to gate valves and butterfly valves of the same size, ball valves are much heavier, especially when using stainless steel material due to its higher specific gravity compared to cast iron and steel. The heavier the valve, the more difficult it is to install and transport. In some cases, when the weight is too large, the valve needs to have a sturdy support stand.

The common sizes of stainless steel ball valves are usually from DN15 to DN300. Although there are larger sizes available, placing orders for them takes longer. For specially designed products, it may take several months to place an order and complete the design.

Stainless steel ball valves and practical applications

Based on their advantages and unique design features, stainless steel ball valves can be applied in various different fields, including:

– Stainless steel sanitary ball valves are used in food production, pharmaceuticals, and beverage manufacturing lines.

– Small-sized stainless steel ball valves with lever handles are widely used in households to control the opening and closing of water taps for domestic use.

– Medium-sized stainless steel ball valves are used in water and fuel pipelines.

– They are used to open and close liquid storage tanks or pressure vessels.

– Most of the components of the valves are made from stainless steel, providing the ability to work with highly corrosive fluids.

– Three-piece stainless steel ball valves are used in systems with high temperatures and pressures.

Please refer to the image below for the application of stainless steel ball valves:

Reliable Supplier of Stainless Steel Ball Valves

Are you interested in stainless steel ball valves? Are you unsure about the suitable products available on the market that can meet your needs? Or perhaps you haven’t found a reputable supplier specializing in ball valve products?

At VIVA, we will address all your concerns and together we will find the most optimal solutions for your system.

With our extensive experience and expertise in the valve industry, we specialize in providing all types of stainless steel ball valves, directly imported from renowned brands such as Toyo, Kitz, Yuzheng, Wonil, and more.

Our products come with complete quality inspection certificates and proof of origin. Before shipment, our technical department conducts thorough inspections to ensure absolute customer satisfaction.

All industrial valve equipment supplied by VIVA is covered by a 12-month warranty against manufacturing defects.

If you need to place an order or have any inquiries related to our products, please contact us directly for assistance.

See more: Bronze Ball Valve

ĐÁNH GIÁ SẢN PHẨM

Đánh giá

Chưa có đánh giá nào.