Structure of compressed

The structure of a compressed air cylinder or a compressed air cylinder is how it is constructed? These are the questions I often receive during the consultation process for compressed air cylinder products.

Therefore, in today’s article, I would like to share knowledge related to the structure of compressed air cylinders.

Understanding Compressed Air Cylinders

A compressed air cylinder is a mechanical device designed primarily for pulling, pushing, lifting, lowering, gripping, or rotating. It operates using compressed air, which is high-pressure air generated by an air compressor.

The compressed air entering the cylinder creates specific pressure differentials, and these differentials result in forces acting on the internal mechanism (piston). As a result, the position of the piston changes, and when the piston changes position, it causes the displacement of other components, typically the movement of the rod (cylinder rod).

There are various types of compressed air cylinders used in specific fields, differing in functionality as well as the structure of the compressed air cylinder.

Commonly used materials for manufacturing compressed air cylinders are aluminum alloys or stainless steel. These materials are chosen for making the main parts of the air cylinder because of their good corrosion resistance and ability to withstand high forces.

Compressed air is used and operated in equipment with pressure ranging from 3 bar to 10 bar for typical applications, and higher for systems serving high-performance requirements.

Common Types of Compressed Air Cylinders

The structure of compressed air cylinders varies depending on each type. Therefore, before delving into the structure of compressed air cylinders, let’s briefly go through some commonly used types of compressed air cylinders.

Compressed air cylinder devices are applied in various systems, with each type serving a specific function. From these types, numerous different variations have been developed. Based on their functionality and basic operating principles, we have the following basic types of cylinders.

Straight Compressed Air Cylinder

For straight compressed air cylinder devices, they convert energy from the compressed air pressure into linear motion along the cylinder body.

Depending on the installation orientation of the cylinder, the device can be used to perform the following motions:

When the cylinder is installed vertically, its function is to lift or lower certain mechanisms, objects, or systems.

When the cylinder is installed horizontally, its function is to pull or push certain mechanisms, objects, or systems.

Regarding straight compressed air cylinders, various other variations have been created, including single-acting cylinders, double-acting cylinders, and double-ended rod cylinders.

Clamp-Type Compressed Air Cylinder

A clamp-type compressed air cylinder is designed to tightly grip specific objects. These cylinder devices are typically installed on moving parts and are used to grip objects for transportation between different positions in manufacturing processes.

Some variations of clamp-type compressed air cylinders include: single-rod clamp air cylinder, double-ended clamp air cylinder, or types with three clamping jaws.

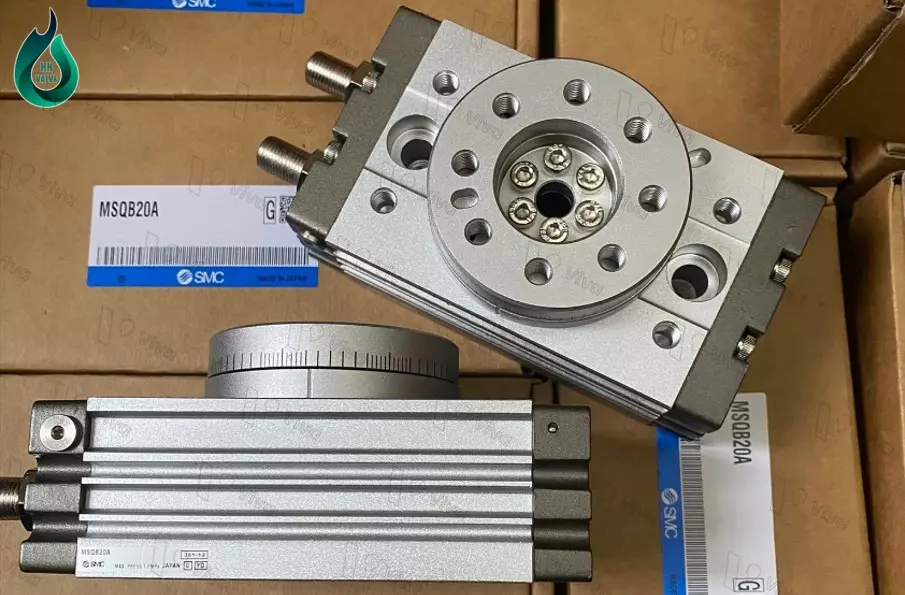

Rotary Compressed Air Cylinder

Rotary compressed air cylinders use high-pressure compressed air to act on the piston located inside the cylinder body. Each piston is designed with an additional rack connected to a gear shaft.

When there is a pressure difference between the chambers inside the cylinder, it causes the piston to move in opposite directions. The linear motion of the piston, through the meshing of the rack and gear, is transformed into rotary motion.

The rotary motion range of a rotary compressed air cylinder is typically 90°, 180°, or 360°.

Structure of a Compressed Air Cylinder

When we mention the structure of a compressed air cylinder, we usually think of the structure of a straight-type compressed air cylinder. It has a long cylinder body designed in a square or circular shape, with a piston connected to a shaft inside. This is easily understandable because straight-type compressed air cylinders are the most commonly used type.

However, to have a deeper understanding of the structure of compressed air cylinders, let’s explore the structure of various types of cylinders together.

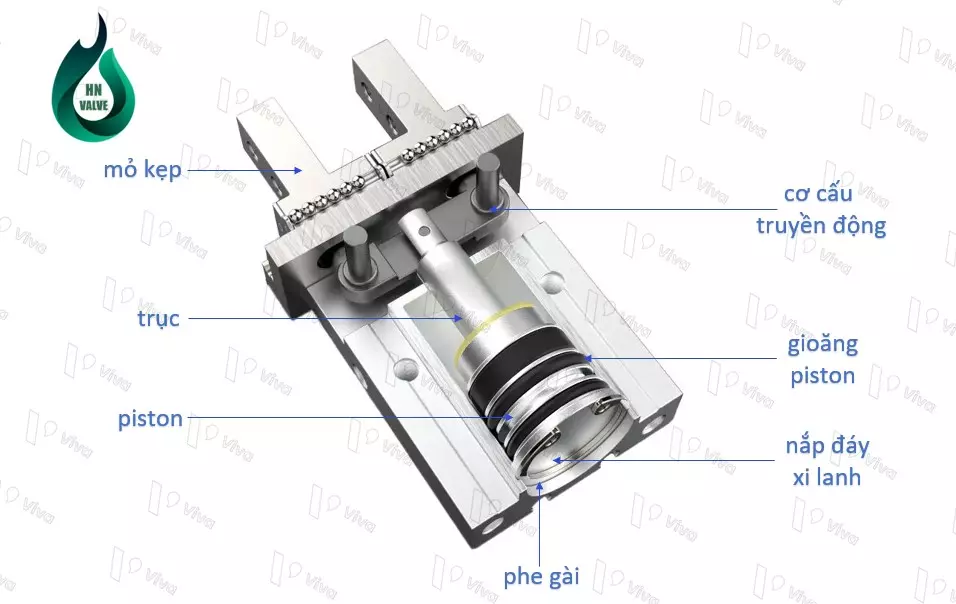

Structure of a Clamp-Type Compressed Air Cylinder

A clamp-type compressed air cylinder is composed of the following basic components:

- Cylinder Body: The body of a clamp-type compressed air cylinder is made of aluminum alloy. It is typically designed in the shape of a rectangular box.

- Piston: Positioned inside the cylinder body, the piston moves along the cylinder body under the influence of compressed air pressure. The piston is also made of aluminum alloy.

- Shaft: The shaft component has one end connected to the driving mechanism, and the other end is linked to the piston. When the piston moves, the shaft also moves accordingly, transmitting motion to the next component.

- Driving Mechanism: This component consists of interconnected parts that receive motion from the shaft and transmit it to the two clamping jaws. The driving mechanism is commonly made of carbon steel or stainless steel.

- Cylinder Bottom Cap: It is a thin round disc made of aluminum alloy, and its purpose is to seal the cylinder body.

- Retaining Clip: This detail is an accessory used to secure the cylinder bottom cap to the cylinder body.

- Clamping Jaws: These directly perform the function of gripping objects. The clamping jaws are made of aluminum alloy or carbon steel.

- Piston Seals: Compressed air pistons in the cylinder require additional seals made of highly elastic materials. These seals function to seal the internal chambers of the cylinder, preventing direct contact between the piston and the cylinder wall, thus avoiding wear and tear.

These are the basic components that make up a compressed air cylinder. In practice, depending on the specific product type, there may be slight variations in the structure.

Structure of a Rotary Compressed Air Cylinder

A rotary compressed air cylinder is a type of cylinder that utilizes high-pressure compressed air to convert it into rotary motion. This rotary motion is not continuous but can only rotate within a certain limited angle. Some commonly applied angle limits for rotary compressed air cylinders are 90, 180, and 360 degrees.

The structure of a rotary compressed air cylinder includes the following main components:

- Cylinder Body: The body is usually made of aluminum alloy or, for devices designed to operate at higher pressures, stainless steel. The body can be designed as a single body or a double body, depending on the required design capacity of the device.

- Piston: Due to the various types of compressed air cylinders, the piston component is also manufactured with diverse shapes and materials suitable for different types of cylinder bodies. The translational motion of the pistons is transformed into rotary motion of the rotating table or a specific axis. The piston components are made with an integral rack.

- Air Supply Ports: To perform the intended functions, rotary compressed air cylinders require appropriate compressed air to be supplied inside. This is achieved through two air supply ports, and changing the air supply port will change the rotational direction of the cylinder component.

- Gear: This component is partially fixed to the body of the compressed air cylinder, and the other end is connected to the rotating table. The gear teeth are meshed with the rack on the piston. This part is made of stainless steel.

- Rotating Table: The rotating table of the rotary compressed air cylinder is made of aluminum alloy and is connected to the gear through various bolted details.

These are the basic components that constitute the structure of a rotary compressed air cylinder. It is important to note that depending on the device’s type, there may be certain structural differences among different types of cylinders.

Structure of a Straight Compressed Air Cylinder

Due to being the most commonly used type among pneumatic cylinders, straight compressed air cylinders come in various types and variations, resulting in certain differences in the number of components, sizes, and shapes.

For straight compressed air cylinders, they are widely known in two basic types: single-acting and double-acting. Both types share a similar structure, with the main difference being that the single-acting compressed air cylinder has an additional internal spring installed within the cylinder body.

The structure of a straight compressed air cylinder includes the following main components:

- Cylinder Body: Similar to other types of compressed air cylinders, the body of a straight compressed air cylinder is primarily made of stainless steel or aluminum alloy. The length of the body will affect the working stroke of the shaft. The diameter of the cylinder body determines the actuating force that the device can generate at the same pressure level.

- Piston: The piston is made of aluminum alloy and is placed inside the cylinder body. It is connected to the shaft component. When the working pressure acts on either side of the piston, it will move, resulting in the motion of the cylinder shaft.

- Shaft: The shaft is made of stainless steel. It experiences frequent impact forces during operation and is designed with a smaller cross-section compared to other components.

- End Cap: The cylinder body is a hollow metal cylinder, so components are needed to connect and limit the motion of the parts. Additionally, to ensure the device operates with optimal efficiency, it is necessary to prevent compressed air leakage from the cylinder. The end cap is designed to meet all these requirements. It is cast from solid aluminum and then machined to achieve the necessary precision.

- Flow Control Valve: This component is integrated into the end cap of the compressed air cylinder and serves to control the flow of compressed air entering or exiting the cylinder body. Controlling the compressed air flow determines the speed of the cylinder shaft’s movement.

- Air Inlet Port: The inlet port is designed to connect with the compressed air piping system. Compressed air from the system will pass through these pipes to enter the cylinder body.

Summary

In this article, which focuses on understanding the structure of compressed air cylinders, I have discussed what compressed air cylinders are, their functions, and types. This information is essential to help us understand why the structure of compressed air cylinders is designed in such a way.

By understanding the structure of compressed air cylinders in a basic way, users can perform maintenance, upkeep, and repairs more easily.

Having a clear understanding of the product’s structure is necessary for system design and calculation, right from the initial stages.

Above is all the relevant information regarding the structure of compressed air cylinders. If you need further clarification on any aspect, please feel free to contact me directly for a more specific discussion. As always, I welcome the valuable input of our readers to further enhance the completeness of the article. Thank you!