Types of plastics

What types of plastics are commonly used? What are the characteristics of these types of plastics? Where are they used?

Have you ever asked yourself these questions? As the author of the article I’m about to share below, these questions have appeared and repeated many times. Every time I choose materials for projects, every time I notice plastic being used excessively around us, and every time the media reports on plastic waste issues.

If you’re also interested in this issue, let’s explore common types of plastics together in today’s article.

Understanding Plastics

Plastic is a widely used synthetic material, known for its advantages such as lightweight, durability, flexibility, ease of molding, and low cost.

It is formed from long-chain molecules called polymers. During the plastic production process, smaller structural units called monomers are combined to form larger units through polymerization.

There are many different types of plastics currently used worldwide, each with its own properties. This means that each type of plastic is suitable for certain applications or a specific range of applications.

Common Types of Plastics

Plastic is a material used in various fields, encompassing numerous varieties, with each type of plastic having its own composition and characteristics.

Let’s explore the commonly used types of plastics today.

PET Plastic

PET (Polyethylene Terephthalate) plastic is a thermoplastic polymer, indicated as PET or PETE, with a chemical formula of (C10H8O4)n.

Characteristics:

- PET plastic is often transparent, and the color of products made from this material is determined by the added dyes during production.

- It is lightweight and highly durable, with resistance to impact, alcohol, and solvents.

- The temperature range for PET plastic is from -60℃ to 130℃ (this temperature range may vary depending on the form, with amorphous PET undergoing shape deformation at around 60℃).

- It exhibits resistance to various chemicals and oxidation.

- It is a recyclable material, aiming to minimize its environmental impact.

Applications:

- PET plastic is widely used in the production of bottles and containers for beverages.

- It is also extensively used in the textile industry to create polyester fibers for clothing, bedding, furniture, and other textile products.

- PET is used as a material in 3D printing.

- Note that PET plastic is recyclable and requires proper processing to optimize its recycling process and reduce its environmental impact.

HDPE Plastic

HDPE (High-Density Polyethylene) plastic is a type of polyethylene with high density. Here is some information about HDPE plastic:

Characteristics:

- HDPE is flexible, versatile, and relatively lightweight.

- It has good impact resistance and strength, along with chemical resistance and water resistance.

- It has poor heat resistance and is typically used within a maximum temperature range of 65℃.

- It is chemically resistant, allowing it to come into contact with diluted acids and bases.

- It is recyclable multiple times.

- It has good electrical insulation properties.

Applications:

- HDPE is widely used in packaging, non-woven bags, water pipes, containers, and construction materials.

- It is also used in the production of toys, household goods, storage boxes, and other industrial products.

- HDPE is utilized in the medical field for manufacturing medical solution bottles, medicine bottles, medical devices, and body-contact products.

PVC Plastic

PVC (Polyvinyl Chloride) plastic is a synthetic plastic with diverse characteristics and wide-ranging applications, particularly in construction.

Characteristics:

- PVC is rigid, durable, and has good water resistance, while being cost-effective.

- It exhibits chemical resistance, fire resistance, and can withstand harsh weather conditions.

- The working temperature limit is 65℃, ensuring durability and preventing deformation of equipment. However, PVC should not be used in excessively high temperatures due to health safety standards.

- It has good electrical insulation properties.

- It can be easily molded, allowing the material to be shaped into various forms.

- It has corrosion and oxidation resistance, making PVC products suitable for outdoor use.

Applications:

- PVC plastic is used in the manufacture of various types of pipes, pipe fittings, valves, such as PVC water pipes, PVC electrically controlled ball valves, PVC butterfly valves, etc.

- It is used to create insulation covers and protective casings for metal components used in corrosive environments.

- In construction, PVC is utilized for manufacturing partition panels, decorative purposes, etc.

LDPE Plastic

LDPE (Low-Density Polyethylene) plastic is a type of polyethylene with low density. Here is some information about LDPE plastic:

Characteristics:

- LDPE plastic has a specific gravity of approximately 917-910 kg/m³ (at room temperature conditions).

- The working temperature limit is 65℃, and it can briefly operate at temperatures up to 90℃.

- It has a melting point of around 110℃.

- It exhibits chemical resistance to diluted acids, bases, and alcohols.

- It has electrical insulation properties.

- It is flexible and highly elastic.

Applications:

- LDPE plastic is used in packaging and wrapping-related tasks. It is used for manufacturing various types of packaging, food storage bags, protective films, etc.

- It is used in household items and tools, such as the production of various household items used in homes and children’s toys.

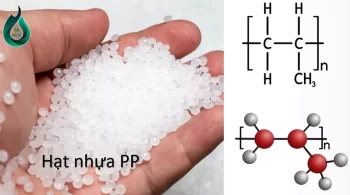

PP Plastic

PP (Polypropylene) plastic is a thermoplastic material that is very lightweight due to its low density and has a high heat resistance. Its chemical formula is (C3H6)n.

As a versatile material, PP plastic exhibits different characteristics depending on the manufacturing process, allowing the PP film to be more suitable for practical application conditions.

Characteristics:

- Melting temperature range: For Homopolymer, it ranges from 160℃ to 165℃, and for Copolymer, it ranges from 135℃ to 159℃.

- Specific gravity: Ranging from 0.898 g/cm³ to 0.908 g/cm³ (depending on the type)

- Chemical resistance to alcohols, acids, bases, esters, ketones, etc.

- Unlike PVC plastic, PP plastic is highly flammable.

Applications:

- PP plastic is widely used in the packaging industry, including packaging materials, non-woven bags, storage boxes, furniture, household items, automobiles, medical products, medical instruments, and various industrial applications.

PS Plastic

PS (Polystyrene) plastic is a material used in solid or foam state, depending on the purpose. Its chemical formula is (C8H8)n. This type of material is relatively inexpensive as it is one of the six most commonly used plastics (technically seven, but group 7 includes various types of plastics, so we won’t count it here).

Characteristics:

- Specific gravity: 0.96 to 1.05 g/cm³

- Melting temperature: 240℃

- Polystyrene is relatively brittle.

Applications:

- In construction and machinery: It is used as insulation material, often injected between partition walls to create an insulation layer for buildings or as insulation for refrigerators and freezers. It has the advantages of good thermal insulation, durability, and resistance to water damage.

- In product packaging: Polystyrene is commonly molded into foam boxes and trays for preserving and protecting food or fragile items.

- In automotive manufacturing: Solid polystyrene is used as a material for making various components and parts in cars, including decorative elements, knobs on dashboards, and sound insulation layers for vehicles.

ABS Plastic

ABS (Acrylonitrile Butadiene Styrene) plastic is a thermoplastic material known for its impact resistance. Its chemical formula is (C 8 H 8·C 4 H 6 ·C 3 H 3 N)n.

Characteristics:

- Specific gravity: 1.06 to 1.08 g/cm³

- Operating temperature range: -20 to 80℃

- ABS plastic is known for its strength, good impact resistance, and compliance with various technical standards. It is also cost-effective.

- The material is not resistant to concentrated sulfuric acid and concentrated nitric acid.

- ABS has good electrical insulation properties.

Applications:

- Electronics: ABS plastic is widely used in the manufacturing of parts for various electronic devices, often as protective casings or insulation components. Examples include keyboards, remote controls, and computer components.

- Household appliances: Many household items such as kitchen tools, bathroom accessories, and furniture have components made from ABS plastic.

- Machinery and equipment: Acrylonitrile Butadiene Styrene is used to manufacture components in machinery and equipment, including protective parts for motorcycles, cars, and various industrial machinery.

Summary

In this article today, we have explored the basics of commonly used plastics. The seven most common types of plastics covered include:

- PET Plastic

- HDPE Plastic

- PVC Plastic

- LDPE Plastic

- PP Plastic

- PS Plastic

- Other types of plastics (such as ABS, PTFE, PC,…)

Each type of plastic has its own distinct characteristics and is suitable for various applications. As you have seen, most plastics have good electrical insulation properties, and many of them can be recycled to minimize environmental impact. Therefore, when products made of plastic are damaged or no longer needed, we should classify them for recycling and reuse. This is a small action that contributes to the sustainable development of humanity.