Water flow rate

What is Water Flow Rate?

Water flow rate is a measurement that evaluates the level of water flow within a specific period of time. It is commonly measured in terms of mass (tons, kilograms) or volume (usually cubic meters) of water moving through a specific cross-section in a unit of time (usually seconds).

Water flow rate plays an important role in various fields, including environmental engineering, water supply and drainage, agriculture, industry, construction, and wastewater systems.

Calculating water flow rate is necessary in many cases to effectively manage water resources, design appropriate pipeline systems and water channels for practical applications.

Furthermore, information about water flow rate is used to assess and monitor water consumption, determine potential hazards from flooding or water shortages, and conduct research on the flow and movement of water in hydrological and other natural environmental systems.

How to Calculate Water Flow Rate

To calculate water flow rate, you need to know the area of the water container and the time it takes for the water to flow through that area. The general formula for calculating water flow rate is:

Flow Rate (Q) = Area (A) x Velocity (V).

Where:

- Area (A) is measured in square units (m²).

- Velocity (V) is measured in length units per time (m/s).

- Flow Rate (Q) is measured in cubic units per time (m³/s).

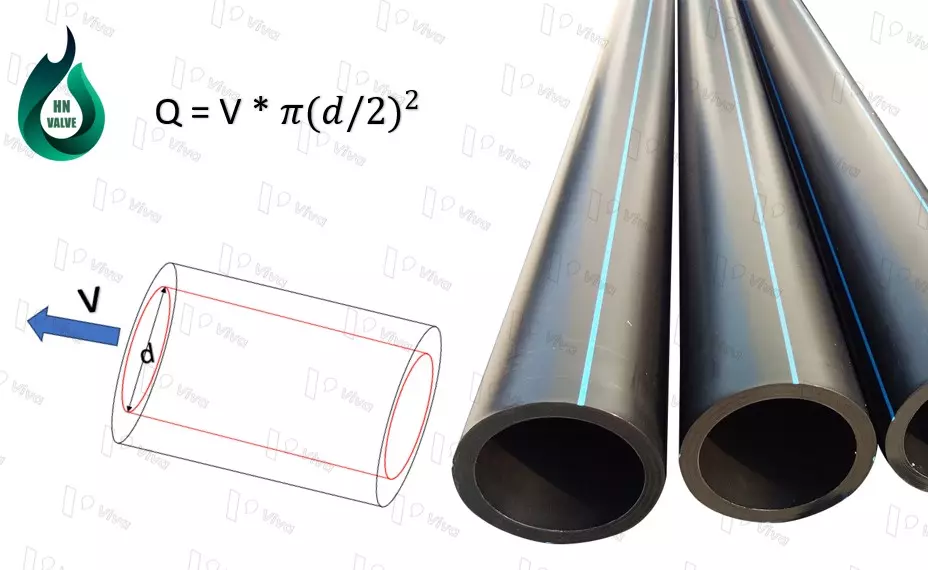

For example, let’s calculate the flow rate of water flowing through an HDPE plastic pipe with an outer diameter of 500 mm and a wall thickness of 23 mm. The flow velocity of water in the pipe is known to be 2 m/s.

- The cross-sectional area of the inner part of the pipe is:

A = (( 500 – 23 * 2)/2)* 3.14 = 712.78 mm² = 0.00071278 m².

- The water flow rate is:

Q = 0.00071278 * 2 = 0.001426 m³/s = 5.1336 m³/h.

Commonly Used Units of Water Flow Rate

Water is a resource used in almost all living and production activities on this planet. Therefore, for each country and different system, the value of water flow rate is expressed in various units, including:

- Liters per second (L/s): This is a common measurement unit for water flow rate in domestic and household applications. It simply represents the number of liters of water flowing within one second.

- Cubic meters per hour (m³/h): This is a widely used unit in the water supply and drainage industry. It indicates the number of cubic meters of water flowing through the cross-section of a flow within one hour.

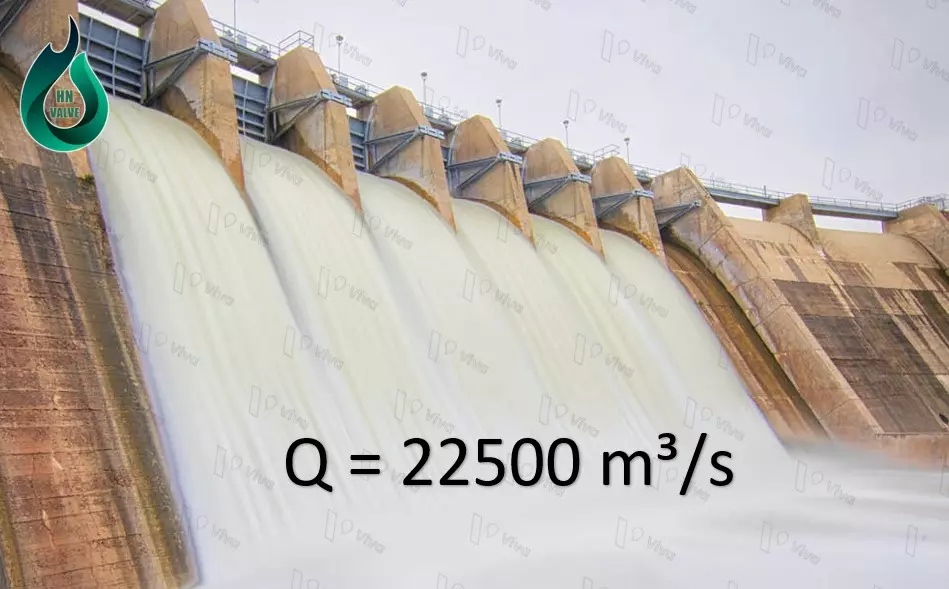

- Cubic meters per second (m³/s): This is a large-scale unit of water flow rate, typically used in industrial applications or large-scale systems. One cubic meter per second is equivalent to the amount of water moving through a point in one second.

- Tons per hour: In many cases, besides using volume per unit of time as the unit of flow rate, mass per unit of time is also used to evaluate water flow rate (commonly applied in industrial applications). Water flow rate is calculated based on the unit of tons per hour, which can be understood as the number of tons of water flowing within one hour. Under normal conditions, 1 ton of water is usually equivalent to 1 cubic meter of water.

- Gallons per minute (gpm): This is a common unit in water supply and drainage applications in North America.

One gallon is equivalent to approximately 3.785 liters, which is approximately 0.00378541 cubic meters (m³). Based on this conversion, to convert from gallons per minute (gpm) to cubic meters per hour (m³/h), you can use the following conversion ratio:

1 gpm ≈ 0.0630902 m³/h

Therefore, to convert from gpm to m³/h, you can multiply the quantity of gpm by 0.0630902.

For example, if you have 10 gpm, you can calculate as follows:

10 gpm x 0.0630902 m³/h = 0.630902 m³/h

Hence, 10 gpm is approximately equal to 0.630902 m³/h.

Commonly Used Water Flow Measurement Devices

Water is an important resource used in daily life and production. As it is a crucial and limited resource, in order to achieve sustainable development goals, we need to use water in the most efficient way possible.

Therefore, laws related to water resource protection have been enacted. Water flow measurement devices have been developed to provide visual data on water consumption and the amount of wastewater generated after water usage.

Mechanical Water Flow Meters

Mechanical water flow meters are devices made entirely of mechanical components and operate based on the flow of water.

As water moves through the meter body, the flow force of the water will act on the turbine or impeller (depending on the specific design), causing rotational motion of this component. This rotational motion is then transmitted through special transmission mechanisms to the meter’s counter (including gears connected to the number wheel). The displayed value on the meter indicates the total water flow that has passed through the meter.

Electronic Water Flow Meters

Electronic water flow meters are provided in a greater variety. The common feature of these devices is that they require electrical power to operate, utilizing sensors and calculations based on a microprocessor.

Ultrasonic Water Flow Meters

These devices use the method of measuring the flow rate of water inside the pipe by emitting an ultrasonic wave into the flowing liquid. Then, a portion of the ultrasonic wave is reflected and received by the wave receiver.

Both the wave receiver and wave transmitter of the measuring instrument are fixedly attached to the pipe. The frequency difference between the wave receiver and wave transmitter is influenced by the velocity of the water flow inside the pipe. Due to the non-contact flow measurement method, ultrasonic water flow meters are particularly suitable for use in measuring wastewater flow.

Electromagnetic Water Flow Meters

Electromagnetic water flow meters are also particularly suitable for measuring the flow rate of water and various types of liquids in general. One point to note is that this device can only perform flow rate measurements for conductive fluids.

An electromagnetic water flow meter creates a magnetic field within its body, and as water flows through the meter, it generates an electromotive force. Electrodes are arranged on the meter body to measure the value of the generated electromotive force (the magnitude of the electromotive force is proportional to the flow rate).

Turbine Water Flow Meters

Turbine water flow meters utilize a turbine wheel that comes into direct contact with the flowing water. As the water passes through the meter body, the force of the water causes the turbine wheel to rotate. However, unlike mechanical water flow meters where the rotational motion of the turbine wheel is transmitted through mechanisms, in the case of electronic turbine water flow meters, the rotational motion of the turbine wheel is non-contact sensing. It is sensed by a speed sensor, and the signal regarding this rotational motion is then encoded and transmitted to a microprocessor. Finally, it is processed and displayed as a flow rate value on the meter’s display screen.