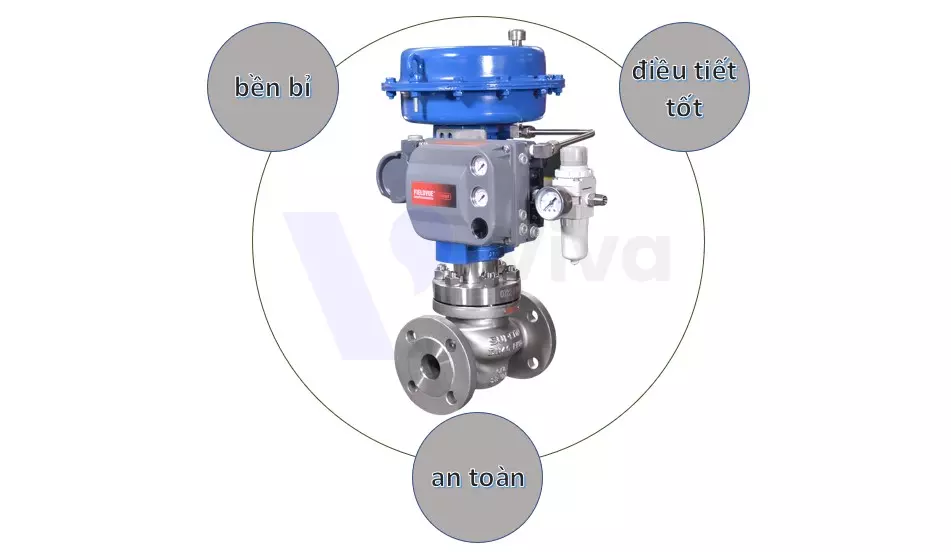

Pneumatically controlled stainless steel globe valve

Giá gốc là: 1.650.000 ₫.1.560.000 ₫Giá hiện tại là: 1.560.000 ₫.

Cập nhật lần cuối ngày 15/06/2023 lúc 08:37 sáng

Overview of pneumatically controlled stainless steel globe valve

Pneumatically controlled stainless steel globe valves are a type of valve that is controlled by compressed air. They have superior durability compared to devices with valve bodies made of materials such as cast iron or steel.

Stainless steel, specifically grade 304 or 316, is used to construct the valve bodies. In addition to their high durability, pneumatically controlled stainless steel globe valves have excellent corrosion resistance and can withstand high temperature and pressure.

The opening and regulating operation of the valve is achieved by lifting and lowering the valve disc at different levels. The valve disc is designed with a specific taper, combined with a special internal structure of the valve body, enabling the device to regulate flow rates much better than plug or butterfly valves.

The valve is operated through a pneumatic actuator.

Learn more

How is a pneumatically controlled stainless steel globe valve constructed?

Pneumatically controlled stainless steel globe valves are manufactured by various companies from different countries, and they come in a wide range of variations. Therefore, the construction of pneumatically controlled globe valves may differ to some extent.

However, in terms of the basic structure of these valves, they share similarities and can be divided into three main components: the pneumatic actuator, the pneumatic signal positioning unit, and the valve body.

Pneumatic actuator for globe valves

The pneumatic actuator for globe valves is a type of actuator that utilizes compressed air and provides linear motion. It is assembled to the valve body using a metal frame and various bolted components.

The housing of the actuator is typically made of steel and is externally coated with epoxy paint to ensure corrosion resistance and protect against adverse environmental conditions.

The pneumatic transmission system of the device is composed of the following components and parts: pneumatic diaphragm, pneumatic spring, drive shaft, bushing, metal frame with spring tray, and some other auxiliary details.

Electro pneumatic positioner for globe valves

This device is an essential accessory for pneumatic control globe valves in general. Before the pneumatic pressure is supplied to the actuator, it passes through the positioner to enhance the control capability of the valve’s opening and closing operations.

The device consists of various specialized mechanisms related to mechanical and electrical components. The lever arm of this device is connected to the valve shaft.

There are multiple types of electro pneumatic positioners used for globe valves, and the complexity of their construction depends on the valve’s function. The more functions the stainless steel globe valve controlled by pneumatic pressure has, the more intricate the positioner’s structure.

Valve Body Components

The body part of the stainless steel globe valve controlled by pneumatic pressure has a similar structure to manually operated globe valves, with the difference being the absence of a detailed handwheel design. Instead, the valve shaft is designed to connect with the drive shaft.

The body of the stainless steel globe valve controlled by pneumatic pressure is composed of the following parts: valve body, valve cover, valve shaft, valve disc, bushing, etc. Most of these components are made of stainless steel.

Some products of pneumatic control stainless steel globe valves at VIVA

Pneumatic control stainless steel globe valves – Normally Closed (NC)

The name “pneumatic control stainless steel globe valves – Normally Closed” indicates the default working state of the valve when it is not subjected to pneumatic pressure, which is the closed state. The valve uses a drive system with a set of springs placed above the pressure sensor diaphragm. Therefore, the spring force acts downward, keeping the valve always in the closed state.

Pneumatic control stainless steel globe valves – Normally Open (NO)

In contrast to normally closed valves, normally open stainless steel globe valves are always in the open state when they are not supplied with operating pneumatic pressure.

The valve’s drive system has a set of springs placed below the barrier diaphragm, and the spring force acts vertically upward. This helps the valve maintain the open state.

Key advantages of pneumatic control stainless steel globe valves

Due to their special structure, simple operating principle, and the use of stainless steel as the valve body material, pneumatic control stainless steel globe valves offer notable advantages, including:

- Excellent flow regulation capability, suitable for both liquids and gases.

- Durable and smooth operation, high stability, and short response time to control signals.

- The valve body and main components are predominantly made of stainless steel, allowing direct contact with corrosive fluids.

- The products are supplied in various types, imported from different manufacturers, suitable for multiple pipeline systems.

- The valve’s drive system operates with pneumatic pressure, limiting potential safety risks related to electrical systems.

Some practical applications of pneumatic control stainless steel globe valves

Pneumatic control stainless steel globe valves are used to regulate the flow of fluids within a system. With numerous outstanding advantages, this equipment is widely utilized in machinery systems, devices, and industrial infrastructure.

A few examples demonstrating the application capabilities of this product line are as follows:

- Used in supply and gas exploration systems.

- Utilized for controlling compressed air systems in production and operation of industrial machinery within factories.

- Applied in supply and exploration systems for fuels such as gasoline or oil.

- Used in various systems that directly handle corrosive chemicals.

- Employed in fuel supply and compressed air systems of ships and vessels.

View more products at Pneumatic control steel globe valves

ĐÁNH GIÁ SẢN PHẨM

Đánh giá

Chưa có đánh giá nào.