Compressed air flow control valve

Giá gốc là: 19.000 ₫.15.000 ₫Giá hiện tại là: 15.000 ₫.

Cập nhật lần cuối ngày 09/08/2023 lúc 04:03 chiều

The compressed air flow control valve compressed air equipment provides an efficient solution to control the flow rate and velocity of compressed air in pipeline systems, allowing for easy adjustment. The equipment is available in various shapes and sizes, depending on practical working conditions.

What is a compressed air flow control valve?

A compressed air flow control valve is a type of valve designed for use in compressed air systems. Its function is to regulate the flow rate of the compressed air passing through the valve. In simpler terms, a flow control valve can adjust the amount of compressed air passing through the valve, whether it is more or less within a given time unit.

The working mode of the valve is adjusted by rotating the adjustment screw on top of the valve body.

Due to its design for use in compressed air systems, the valve is directly installed in the compressed air pipeline or mounted on other devices such as compressed air cylinders, distribution valves, etc. Therefore, compressed air flow control valves are often characterized by compact design and commonly installed using threaded connections or quick-connect fittings designed for this purpose.

Technical specifications of compressed air flow control valve

As you may already know, compressed air flow control valves are primarily used in compressed air systems. They are installed on pipelines or other compressed air equipment to regulate the flow rate of compressed air.

Because of this, in order to choose the appropriate compressed air flow control valve, besides understanding the system well, we need to have a good grasp of the technical specifications of the valve.

Below are the summarized technical specifications of the compressed air flow control valve products provided by VIVA.

- Valve port diameter: 4mm, 6mm, 8mm, etc.

- Connection type: Quick-connect fitting, threaded connection

- Valve body design: Straight body, right-angle body

- Optional valve body materials: Plastic or Stainless Steel

- Working pressure range: 0 ~ 10 bar, 0 ~ 20 bar, etc.

- Working temperature: 0℃ ~ 60℃

- Working fluid: Compressed air

- Product origin: Germany, Taiwan, China, Japan, etc.

- Warranty: 12 months warranty for the product.

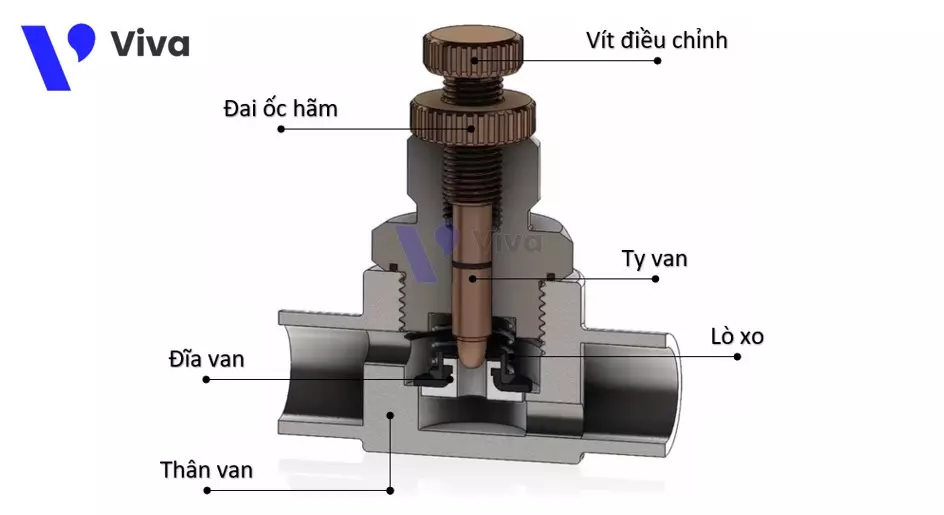

Structure of compressed air flow control valve

The compressed air flow control valve is a type of compressed air device used in various specific applications related to compressed air. Understanding the structure of the product is necessary during its practical use.

Understanding the structure of the product helps users perform installation and adjustment operations accurately, especially in many cases where users can temporarily resolve certain unexpected issues.

Although the compressed air flow control valve is available in different types, each type of valve has certain differences in structure.

However, the compressed air flow control valve is fundamentally composed of the following main components:

- Valve body: The body part of the compressed air flow control valve functions to connect various parts together to form a unified entity. The valve body is designed with connections at each end, allowing the compressed air flow control valve to be easily connected to the working equipment while ensuring sealing and the ability to withstand pressure from the compressed air.

- Valve disc: This component is usually designed in one-way flow control valves (valves that can regulate flow rate in only one direction as indicated beforehand; if the fluid flows through the valve in the opposite direction, it will not have the regulating effect).

- Spring: This component generates elastic force to press the valve disc against the valve body. When the fluid flows in the opposite direction and creates sufficient pressure, the valve disc opens, allowing the fluid to pass through the valve, and the valve loses its flow control effect for the compressed air flow.

- Valve stem: Also known as the valve spindle, the end of the valve stem is designed with a special shape to adjust the flow cross-section of the compressed air when passing through the valve by means of screw adjustment.

- Locking nut: This component is connected to the adjustment screw and is matched with threads between the two parts. The locking nut is responsible for fixing the opening degree of the compressed air flow control valve after adjustment.

- Adjustment screw: This is the part directly operated by the user to regulate the flow rate of the fluid inside the system.

The above are the most basic components that make up the compressed air flow control valve. In reality, this device also requires many other auxiliary components, including various types of gaskets, sealing rings, and thrust bearings. The detailed structure will depend on each manufacturing unit.

Operation of compressed air flow control valve

The compressed air flow control valve is specially designed with high precision to regulate the flow rate of compressed air passing through the valve body. The operation of flow regulation by the valve is relatively simple, achieved through the principle of changing the cross-sectional area of the flow passing through the valve body.

The process of changing the cross-sectional area of the valve body is carried out by rotating the adjustment screw of the valve. When we rotate the adjustment screw counterclockwise, the valve stem is raised, expanding the internal cross-sectional area of the valve body, allowing a greater flow rate of compressed air to pass through the valve.

Conversely, when we rotate the adjustment screw clockwise, the valve stem is lowered, narrowing the internal cross-sectional area of the valve body, reducing the flow rate of compressed air passing through the valve.

In particular, for one-way compressed air flow control valves, there is the additional operation of the spring and the valve disc (or blocking plate). When the compressed air flows in the opposite direction, the pressure of the compressed air will act in the opposite direction to the force exerted by the spring. With sufficient pressure, the valve disc will open, allowing the fluid to pass through. This means that in the reverse direction, the compressed air passing through the valve will not be regulated (for one-way compressed air flow control valves).

Classification of compressed air flow control valves

There are various ways to classify compressed air flow control valves. In this article, I will classify these devices based on their basic functions. There are two types of compressed air flow control valves used to assist in controlling the flow of compressed air through a system, including one-way compressed air flow control valves and two-way compressed air flow control valves.

One-way compressed air flow control valves

The term “one-way flow control valve” here means that the device regulates the flow rate of compressed air in a fixed direction. It is designed and marked with symbols on the valve body.

In the reverse direction, compressed air can still flow through the valve body, but the flow rate cannot be regulated in this direction. The valve is typically used to control the working speed of reciprocating pneumatic cylinders.

Two-way compressed air flow control valve

A two-way flow control valve has the ability to regulate the flow rate of compressed air in both the forward and reverse directions. With this function, the valve is often used in conjunction with a single-acting pneumatic cylinder to achieve higher efficiency in compressed air regulation during operation.

Product Consultation Support

Currently, we offer a wide range of different types of compressed air flow control valves. These products are directly imported from manufacturing units in various countries, including Germany, China, Japan, and more.

The valves are provided in various sizes and designs, designed to meet the optimal requirements of compressed air regulation. With years of experience in supplying industrial equipment, we understand that choosing the right device for your working system requires a good understanding of various technical factors.

Therefore, at VIVA, we have a team of technical experts ready to support customers and provide recommendations for suitable products based on their needs and working conditions.

See more products: compressed air hoses.

Đánh giá

Chưa có đánh giá nào.