Mass flow meter

Giá gốc là: 30.000.000 ₫.26.000.000 ₫Giá hiện tại là: 26.000.000 ₫.

Cập nhật lần cuối ngày 16/06/2023 lúc 02:39 chiều

Dear friends, continuing our series of articles on flow measurement devices, today we will explore mass flow meters, a type of flow meter that utilizes the method of measuring mass flow, which means determining the mass of fluid passing through a cross-sectional area of a pipe per unit of time.

That is why these devices are called mass flow meters. If you are interested in this type of measuring instrument and would like to learn more about it, I hope this article will provide you with useful information.

Understanding Mass Flow Meters

The English term for đồng hồ đo lưu lượng khối lượng is “Mass Flow Meter.” It is a type of measuring device capable of measuring the flow rate of various substances, including gases and liquids.

The value measured by a mass flow meter is expressed in terms of the mass of fluid flowing through a specific position in the pipe per unit of time.

Example: kg/h, lb/min, etc.

Instead of expressing the measured value in terms of volume per unit of time.

Example: m³/min, m³/h, etc.

Using mass units over a unit of time provides more accurate measurements because, as you may know, the volume of different fluids within a system is affected by temperature factors, specifically:

As the temperature increases, the fluid tends to expand, leading to an increase in volume.

As the temperature decreases, the fluid tends to contract, resulting in a decrease in volume.

The mass of the fluid is not affected by temperature factors. Therefore, mass flow meters are considered the most accurate devices compared to other types of flow meters that utilize different measurement methods such as:

- Electromagnetic flow meters

- Vortex flow meters

- Turbine flow meters, etc.

Due to their higher accuracy in flow measurement, mass flow meters naturally have a higher cost compared to other flow meter types.

Currently, there are two different methods used in mass flow meters, and each method corresponds to a different type of flow meter, resulting in two different types of mass flow meters:

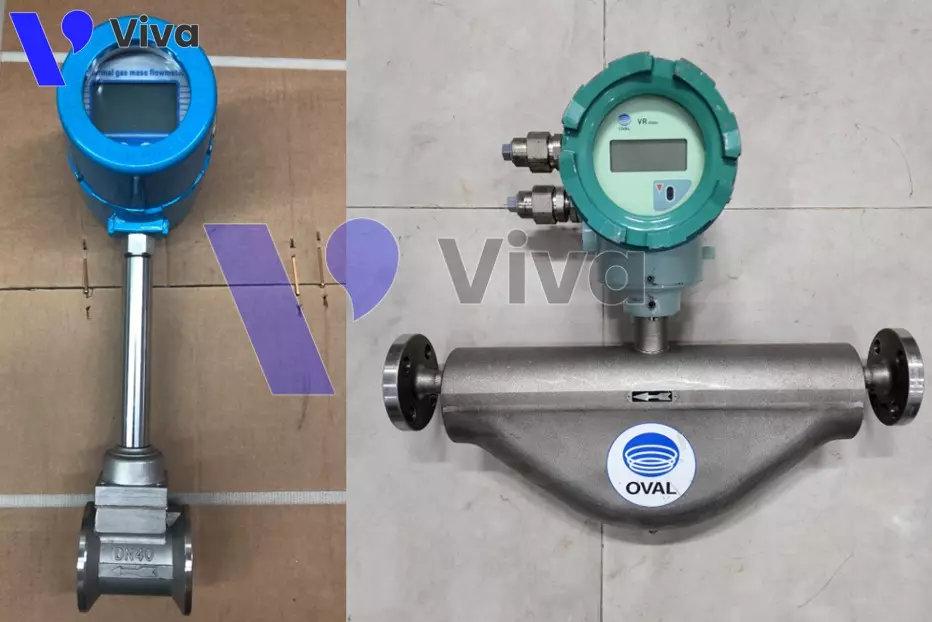

- Coriolis mass flow meters

- Thermal mass flow meters

Basic Technical Specifications

Mass flow meters are supplied with two product lines that apply different principles. From these two lines of flow meters, manufacturers have conducted research and development to introduce various product variations with unique characteristics. The following is a compilation of the basic technical specifications of mass flow meters, which readers can refer to for better understanding and a more comprehensive view of this type of flow meter.

- Device: Mass Flow Meter

- Types: Coriolis Mass Flow Meters, Thermal Mass Flow Meters

- Flow Meter Body Diameter: DN15 to DN 400

- Applicable Fluids: Liquids, Gases, Sludge, etc.

- Fluid Temperature: -50℃ to 125℃, -50℃ to 200℃, -50℃ to 300℃, etc.

- Power Supply: From 18 to 36V-DC, from 85 to 265V-AC

- Operating Pressure of the Fluid: 1.6 MPa, 2.5 MPa, 4.0 MPa, etc.

- Output Signal: 4-20mA

- Measurement Accuracy: 0.1%, 0.2%, 0.5%, etc. (depending on the model)

- Mass Flow Rate Range: 15~3000 kg/h, 40~8000 kg/h, 250~50000 kg/h, etc.

- Origin: USA, Germany, China, Japan, etc.

- Warranty Policy: 12 or 18 months (depending on the product).

Development History of Mass Flow Meters

Mass flow meters are important measuring devices used in various industries. The development history of this type of flow meter began in the 1960s and has gone through several stages of development.

1960s: The first thermal mass flow meters were developed by applying the heat transfer principle. They had low accuracy and were only used in simple applications.

1970s: The Coriolis mass flow meter was invented by a group of engineers at Micro Motion, Inc. in Boulder, Colorado. Led by Richard A. Crane, who had previously worked in the field of developing nuclear power plants, Crane and his team realized that by measuring the Coriolis force generated by the flowing fluid through vibrating tubes, they could accurately measure the mass flow rate of the fluid. This type of flow meter applies the Coriolis effect to measure the mass flow rate of the fluid passing through a special tube.

The Coriolis effect was first mentioned by French mathematician Gaspard-Gustave de Coriolis in 1835.

1980s: Coriolis mass flow meters were widely used in various systems in different fields. They were highly regarded for their measurement accuracy, stable and reliable performance.

1990s: During this period, mass flow meters were further developed with higher accuracy, durability, and the ability to operate in harsh environments.

Today, with the strong development of science and technology, mass flow meters have been developed with higher accuracy. In particular, Coriolis mass flow meters have been redesigned to be more compact, making installation easier and more convenient. The size limits of the products have been increased to accommodate pipes up to DN400.

Classification of Mass Flow Meters

Coriolis Mass Flow Meters

Coriolis mass flow meters are flow meters used to measure the mass flow rate of gases or liquids based on the Coriolis principle.

Currently, this type of flow meter leads in measurement accuracy, which is why their prices are often higher compared to other flow meter types.

Due to their high cost, Coriolis flow meters are not widely used. They are only applied in certain critical systems that require high accuracy or for measuring the flow rate of valuable fluids such as oil and gasoline, where measurement errors directly affect the profitability of the parties involved.

Although they are the most advanced flow measurement devices, they still have some limitations, such as their large size and weight, which pose certain challenges during installation. The significant price difference also makes them less accessible to users.

Thermal Mass Flow Meters

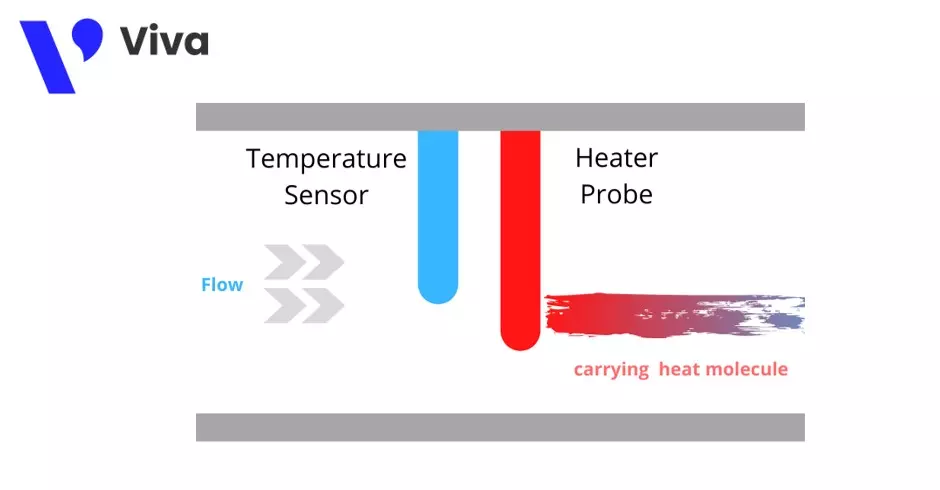

These devices measure the mass flow rate of fluids inside pipes using the heat transfer principle. The process is as follows: the thermal mass flow meter is designed with two temperature sensors, one of which emits heat. During system operation, the flowing fluid in the pipe comes into contact with the heat-emitting sensor and absorbs its heat.

The higher the flow velocity, the greater the heat loss from the meter’s thermal sensor. The remaining sensor measures the temperature of the fluid in the system.

Thermal mass flow meters have a compact structure, provide high-accuracy mass flow measurements, and are less affected by factors such as pressure, temperature, and fluid viscosity. They have a wide measurement range and lower cost compared to Coriolis mass flow meters.

However, thermal mass flow meters also have some limitations, including:

- They can only measure the flow rate of clean gases without impurities to limit sensor wear and tear.

- Although their cost is lower compared to Coriolis mass flow meters, they are still relatively expensive compared to many other types of flow meters.

- In systems with hot air or compressed gas, moisture directly affects the measurement accuracy of the device. Condensation not only affects the durability of the meter but also impacts the sensor heads.

- Understanding the system and the properties of the fluid is essential to ensure the meter provides the highest measurement efficiency, as the calibration process can be relatively complex.

Principles of Mass Flow Meters

Due to the availability of mass flow meters in two different product lines, each type of flow meter applies different working principles. Let’s explore the working principles of each product type.

Principle of Operation for Thermal Mass Flow Meters

Firstly, thermal mass flow meters are designed to measure the mass flow rate of various gases based on the heat transfer phenomenon.

These devices measure the flow rate by introducing a specific amount of heat into the fluid to be measured through a metal heat emitter.

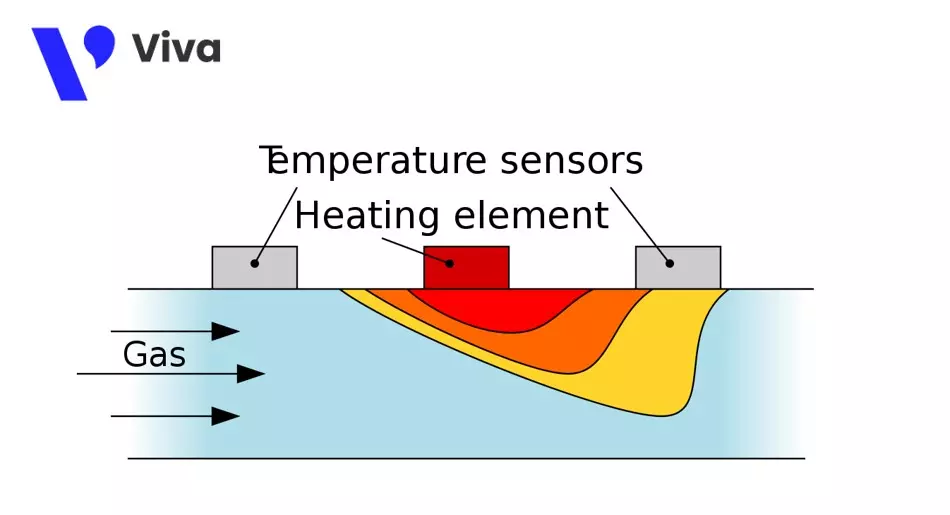

There are two different measurement methods applied to this flow meter, including:

Power Consumption Determination Method

When the working fluid comes into contact with the heat emitter, it absorbs a certain amount of heat to maintain the heat level of the heat emitter. The microprocessor unit of the flow meter calculates the electrical power required to transmit to the heat emitter. The more heat is absorbed by the flowing fluid, the more electrical power is needed to maintain the temperature.

During operation, as the fluid flow rate passing through the flow meter increases, it absorbs more heat. By combining these two relationships, it is possible to determine the mass flow rate of the working fluid.

Temperature Differential Method

With this measurement method, the fluid is directed into a pipeline where a dual heat emitter is arranged. Two temperature sensors are placed before and after this device to measure the temperature difference of the fluid after passing through the heat emitter.

The heat generated by the heat emitter is constant, and the flow meter is calibrated to match the characteristics of the fluid. Therefore, the temperature difference measured by the two sensor ends is inversely proportional to the flow rate of the fluid.

To understand this principle better, please refer to the calculation formula provided by the Omega flow meter manufacturer on their website:

m = Kq/(Cp(T2 – T1))

Where:

- Mass flow rate (m).

- Measured temperature differential (T2 – T1).

- Flow meter coefficient (K).

- Thermal power ratio (q).

- Specific heat capacity of the fluid (Cp).

These are the two basic principles applied to various thermal mass flow meters. In practical applications, many devices will utilize this principle, while some variations may exist depending on the research and development by different manufacturers.

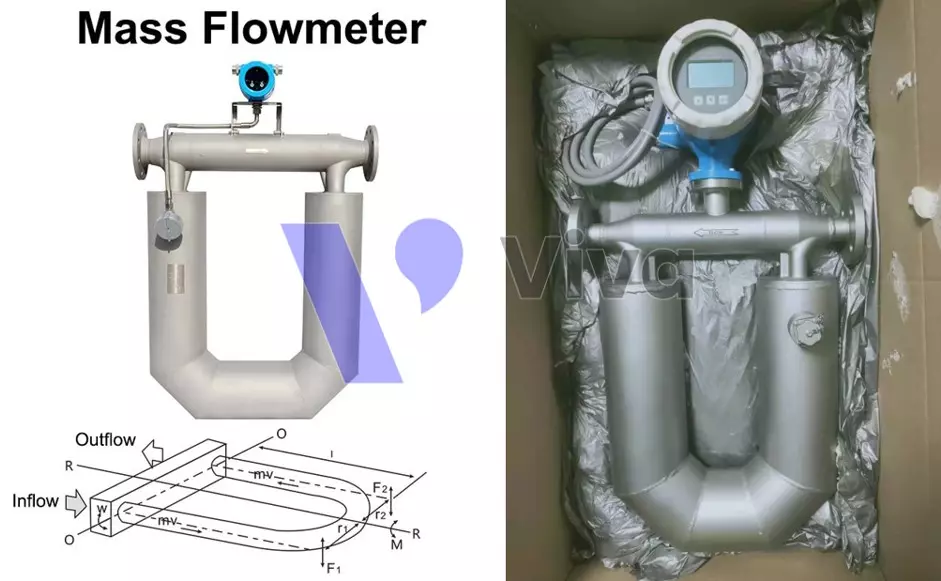

Principle of Operation of Coriolis Mass Flow Meter

True to its name, the Coriolis mass flow meter operates based on the Coriolis effect.

Fundamentally, the Coriolis effect can be understood as the tendency of all moving objects on a rotating plane to drift to one side. This phenomenon was discovered by the physicist and mathematician Gaspard-Gustave de Coriolis, and his name is used to designate this effect. The force that causes the deflection of the motion of an object is called the Coriolis force and is represented by the following formula:

F = -2m × ω × v

Where:

- F is the Coriolis force (N).

- m is the mass of the moving object (kg).

- ω is the angular velocity of the rotating plane (rad/s).

- v is the velocity of motion of the rotating plane (m/s).

- The “-” sign in the formula indicates the force acts opposite to the direction of velocity.

Based on this principle, in Coriolis mass flow meters, the fluid to be measured flows into specially shaped tubes. These tubes are designed to oscillate perpendicular to the flow direction, thanks to a specialized component. This generates an artificial Coriolis force that acts on the flow of the fluid, creating a torsional force that displaces the phase oscillation of the tubes from their initial state. The magnitude of the phase displacement force is directly proportional to the mass of the fluid passing through the flow meter.

Why Use a Mass Flow Meter?

A mass flow meter is a device designed to measure the mass flow rate of a fluid within a pipeline system. In addition, it integrates additional functions such as pressure and temperature measurements (depending on the specific product). These functions are commonly found in many other types of flow meters as well.

So why do many systems still use mass flow meters, despite their higher cost and overlapping features with other flow meters? Let’s explore the reasons below:

- High accuracy: The main advantage of using a mass flow meter in various critical systems is its ability to provide highly accurate measurements of fluid flow. Instead of relying on volumetric flow measurements to derive the mass of the fluid, mass flow meters directly measure the mass. This direct measurement method offers improved accuracy because it is not affected by factors such as temperature, pressure, or fluid viscosity.

- Cost calculation and management: Due to their high accuracy and ability to measure mass flow, these flow meters are commonly used for cost calculation and management purposes, especially for high-value fluids such as petroleum products. Since the volume of petroleum products changes with temperature, using a mass flow meter ensures the most accurate cost determination.

- Stable measurements in various operating conditions: Mass flow meters are considered the most advanced flow meters currently available. They incorporate modern technologies and utilize various sensors combined with appropriate calibration, allowing them to operate reliably and consistently in a wide range of operating conditions.

Applications of Mass Flow Meters

Mass flow meters, with their exceptional functionality and accuracy, can be applied to a wide range of systems and different working conditions. However, due to their high cost, they are prioritized for use in specific, critically important systems that require high accuracy.

These systems often directly impact economic efficiency or involve the blending of different fluids with strict accuracy requirements for mixing ratios and components used in the system.

Some practical applications of mass flow meters include:

- In the petroleum industry: These devices are used to measure the quantity of gasoline, petroleum, and natural gas during transactions and transfers between working units. Mass flow measurements provide high reliability in varying temperature conditions, ensuring accurate pricing of gasoline, petroleum, natural gas, and other products. With high precision, they ensure transparency in transactions between parties.

- In the chemical industry: Mass flow meters are used to assist users in efficiently controlling the mixing ratios of various chemicals, thanks to their superior accuracy. Mixing ratios play a crucial role in chemical-related manufacturing processes.

- In the energy industry: These meters are employed to monitor the quantity of fluid used in different stages of energy systems. Accurate flow measurements help users evaluate the system’s performance. By comparing the input resources and the obtained useful energy, appropriate adjustments can be made to ensure the system operates at its optimal efficiency, thereby enhancing economic effectiveness.

Explore more products: hot steam flow meters.

Đánh giá

Chưa có đánh giá nào.