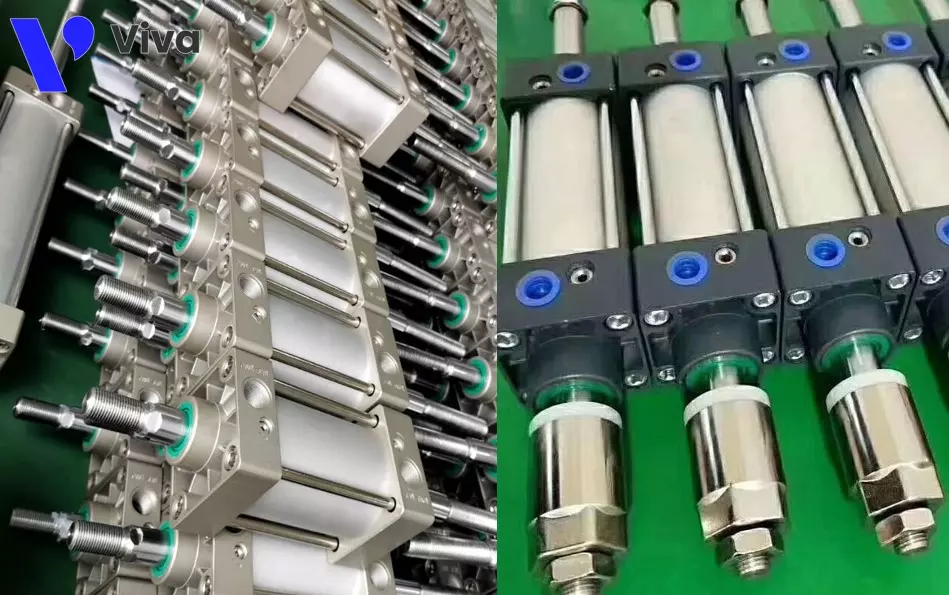

Two headed pneumatic cylinder

Giá gốc là: 130.000 ₫.120.000 ₫Giá hiện tại là: 120.000 ₫.

Cập nhật lần cuối ngày 09/08/2023 lúc 03:51 chiều

What is a two-headed pneumatic cylinder?

A two-headed or double-acting pneumatic cylinder is a term used to refer to a type of pneumatic cylinder that is specially designed with two piston rod components (push rods). They are designed on the same axis but in opposite directions, with one end of the cylinder facing upward and the other end facing downward.

Two-headed pneumatic cylinders are supplied in two main variants: single-acting two-headed pneumatic cylinders and double-acting pneumatic cylinders.

The main function of this device is to convert the energy of compressed air into linear motion. With the unique design of a two-headed pneumatic cylinder, it can provide both pulling and pushing motions to the piston rod simultaneously.

Compressed air required to operate the device typically ranges from 2 bar to 16 bar (depending on the specific type, this pressure range may vary).

Most of these devices are made of aluminum alloy or stainless steel, which are highly regarded for their durability and pressure resistance.

Technical specifications of two-headed pneumatic cylinder

Two-headed pneumatic cylinders operating with compressed air are a product line currently available at VIVA, consisting of various different types to help customers choose products suitable for their specific purposes.

We provide the technical specifications of the equipment below:

- Product line: Two-headed pneumatic cylinder

- Basic material options: Aluminum alloy, stainless steel

- Connection port sizes: 1/8 inch, 1/4 inch, 3/8 inch,…

- Piston diameter sizes: 40 mm, 50 mm, 63 mm, 80 mm,…

- Operating temperature: -10℃ to 70℃

- Compressed air pressure range: 2 bar to 16 bar

- Travel speed: From 50 mm/s to 800 mm/s

- Type of operation: Double-acting or single-acting

- Manufacturing companies: STNC – China, Festo – Germany, Airtac – Taiwan.

- Product warranty period: 6 to 12 months.

Structure and operation of two-headed pneumatic cylinder

Structure

A two-headed pneumatic cylinder has a relatively simple structure and is fundamentally similar to a conventional pneumatic cylinder. However, this product line has a small difference, which lies in the piston rod component. Let’s explore the structure in more detail below.

The basic structure of a two-headed pneumatic cylinder includes:

- Cylinder body: The cylinder body is a cylindrical tube made of aluminum alloy or stainless steel, containing internal components. The diameter and length of the tube depend on the size and power of the cylinder.

- Piston: For conventional pneumatic cylinders, a single piston is designed and placed inside the cylinder body. However, there are special designs with multiple pistons evenly spaced. The use of multiple pistons increases the contact area between the piston and the compressed air, allowing for greater impact force with the same pressure. Aluminum alloy is a commonly used material for manufacturing pistons.

- Rod: The rod of a two-headed pneumatic cylinder is unique compared to conventional devices. It consists of two components connected to the pistons in opposite directions. Both components are made of stainless steel.

- Sealing rings: This is an assembly of multiple parts installed on the piston. Their function is to seal the gap between the cylinder body and the piston, preventing direct contact and wear caused by friction. The sealing rings are typically made of NBR rubber or Teflon.

- End caps: The end caps can be considered as part of the cylinder body. They consist of two caps (head cap and tail cap) made of aluminum, produced through casting and then undergo cutting and finishing processes. Each cap is designed with air supply ports and two flow control valves, which can adjust the travel speed of the piston rod.

The above is the basic structure of a two-headed pneumatic cylinder. In practice, due to different manufacturing units, there may be slight variations in the detailed structure.

Operation

The operation of a two-headed pneumatic cylinder is based on the differential force acting on the opposite sides of the piston. This force difference is controlled and regulated through changes in the air supply ports, adjusting the pressure and flow rate of the compressed air provided to the cylinder.

The specific operation of a two-headed pneumatic cylinder is as follows:

At the initial state, the piston head is in a balanced position. When compressed air is supplied to the cylinder body through port B, the pressure of the compressed air exerts a pushing force on the piston, causing it to move in the direction of the arrow.

When the force acting on the piston is sufficient, the piston will move in the same direction as the force applied. The magnitude of the force is determined by the formula:

F = P × (S1 – S2)

Where:

- F is the force acting on the piston (N)

- P is the pressure of the supplied compressed air to the cylinder body (N/m²)

- S1 is the cross-sectional area of the piston (m²)

- S2 is the cross-sectional area of the rod (m²).

As the piston moves, the rod connected directly to the piston will also move. Since there are two rod components, one will have an outward stroke while the other will have an inward stroke.

When the air supply port is switched, this process will repeat but in the opposite direction. This completes one working cycle of the two-headed pneumatic cylinder.

Applications of Two-Headed Pneumatic Cylinder

In terms of application capabilities, in reality, two-headed pneumatic cylinders are not as commonly used as conventional cylinders. However, they frequently appear in various industrial production systems, especially in complex systems on a large scale.

Due to their unique design, two-headed pneumatic cylinders can perform simultaneous pulling and pushing operations, which is why they play an important role in certain special cases.

Some examples of the application capabilities of two-headed pneumatic cylinders include:

- They are used in automated machinery systems to perform operations such as lifting, lowering, pulling, or pushing objects.

- They are employed in compressed air systems in large-scale factories, particularly in heavy industries.

- On a smaller scale, they are utilized in operating various types of machinery and equipment, including industrial valves, product cutting machines, and product sorting mechanisms.

Two-Headed Pneumatic Cylinder Products at VIVA

VIVA Company is a specialized provider of industrial equipment. With years of experience, we have noticed a significant increase in customer interest in the two-headed pneumatic cylinder product line.

Understanding the advantages, disadvantages, and application capabilities of these products, we have undertaken imports from various countries. The equipment is manufactured using advanced technology production lines, undergoes rigorous testing and evaluation processes, and is deemed capable of meeting the working conditions in Vietnam.

As you may already know, this product line is available in various types and variations. To accurately select products that meet the specific needs of customers, we have a team of dedicated staff ready to assist with any inquiries related to the products.

See more products at pressure switches.

Đánh giá

Chưa có đánh giá nào.