What is flow rate? – Units of flow measurement

Flow rate is a very important concept in pipeline systems and industrial equipment. It relates to the mass or volume of fluid or gas passing through a unit of time. To measure flow rate, various units of measurement are used, such as liters per second, cubic meters per hour, cubic feet per minute, and many others. However, not everyone understands flow rate and how to measure it accurately. Therefore, the following article answers these questions and provides basic information about flow rate.

What is flow rate? – What is water flow rate?

What is the concept of flow rate?

Flow rate is commonly defined as the mass (or volume) of a fluid passing through a specific point within a unit of time. The commonly used unit of measurement for flow rate is cubic meters per second (m³/s) or cubic meters per hour (m³/h).

Flow rate is often used to describe the movement of fluid in piping systems, pipelines, flow meters, water treatment systems, and many other applications. The measurement and control of flow rate are crucial to ensure the efficient and safe operation of these systems.

Methods for measuring flow rate often include measuring pipe flow by measuring diameter and fluid velocity, measuring flow rate using pressure sensors, measuring flow rate using oscillating sensors, and many other methods. These methods each have their own advantages and limitations, depending on the specific application, and users will choose the most suitable method to measure the volume of fluid moving within the system.

What is Water Flow Rate?

Water flow rate is a technical concept used to indicate the movement of water through a specific location within a certain period of time. Water flow rate is measured in terms of the volume of water per unit of time, often measured in cubic meters per second (m³/s) or cubic meters per hour (m³/h).

Water flow rate is an important factor in the management and control of water resources. Applications of water flow rate include measuring the flow rate of natural water sources such as rivers, lakes, and canals, as well as assessing the performance of water treatment devices, water pumps, water supply systems, and drainage systems.

To measure water flow rate, flow measurement devices such as flow meters, radiation detectors, flow sensors, and pumps are used. The methods of measuring water flow rate may vary depending on the intended use and actual circumstances, and must be performed correctly to ensure the accuracy and reliability of measurement results.

Examples of Flow Rate Measurement

There are numerous examples of flow rate measurement applied in various fields. Here are some common examples:

- Measuring water flow rate in households: To ensure an adequate supply of clean water for households, it is necessary to measure the water flow rate being used. This can be done using a simple water flow meter, typically installed at the inlet of the water pipeline.

- Measuring oil flow rate in industrial settings: In industries related to petroleum, measuring oil flow rate is crucial to ensure efficient production processes. This can be done using oil flow measurement devices such as flow sensors, pressure gauges, and other flow measurement equipment.

- Measuring gas flow rate in exhaust gas treatment systems: Exhaust gas treatment systems in industrial plants require measuring gas flow rate to comply with environmental and occupational safety standards. This can be done using gas flow measurement devices such as radiation detectors, flow sensors, and other flow measurement equipment.

The examples above are just a few among many applications of flow measurement in daily life and various industries.

Commonly Used Flow Measurement Units

There are many flow measurement units used in engineering, but the most commonly used units are:

- Cubic meters per second (m³/s)

- Cubic meters per hour (m³/h)

- Cubic feet per hour (ft³/h)

- Liters per second (L/s)

- Gallons per minute (GPM)

Cubic Meters per Second (m³/s)

Cubic meters per second (m³/s) is a flow measurement unit used in engineering to measure the volume of water flowing through a specific location within a unit of time. This unit represents the number of cubic meters of water flowing through a specific point in one second. It is the standard measurement unit in the international system and widely used in applications related to large water flow, such as measuring river flow, reservoirs, canals, and industrial water treatment systems.

One cubic meter is equivalent to the amount of water that can fit inside a rectangular block with length, width, and height all equal to 1 meter. It is equivalent to 1000 liters of water or approximately 264.17 gallons.

Cubic Meters per Hour (m³/h)

Cubic meters per hour (m³/h) is a commonly used flow measurement unit in water supply and water treatment applications. This unit represents the number of cubic meters of water flowing through a specific point in one hour. It is one of the most common flow measurement units in civil and small-scale industrial applications.

One cubic meter per hour is equivalent to the flow of water through a specific point in one hour with a flow rate of 1 cubic meter per hour. It is equivalent to 1000/3600 cubic meters per second, approximately 0.2778 cubic meters per second, or 277.78 liters per minute.

Cubic Feet per Hour (ft³/h)

Cubic feet per hour (ft³/h) is a flow measurement unit used in applications related to gas and liquid flow. This unit represents the number of cubic feet of liquid or gas flowing through a specific point in one hour. It is one of the most common flow measurement units in industrial applications and plays an important role in monitoring and controlling production processes.

One cubic foot is equivalent to the volume of a rectangular solid with length, width, and height each equal to one foot. It is equivalent to about 28.32 liters or 7.48 gallons.

Liters per second (L/s)

Liters per second (L/s) is a unit of flow rate used in water supply and water treatment applications. This unit represents the number of liters of water flowing through a specific point in one second. It is one of the most common units of flow rate measurement in domestic and small-scale industrial applications.

One liter per second is equivalent to the amount of water flowing through a specific point in one second with a flow rate of 1 liter per second. It is equivalent to 0.001 cubic meters per second or 3.6 cubic meters per hour.

Gallons per minute (GPM)

Gallons per minute (GPM) is a unit of flow rate used in water and oil applications. This unit represents the number of gallons of liquid flowing through a specific point in one minute. It is one of the most common units of flow rate measurement in industrial and household applications.

One gallon is equivalent to about 3.785 liters. To convert flow rate units from GPM to L/s, the formula 1 GPM = 0.063 L/s can be used.

Flow Rate Calculation Formula

The flow rate calculation formula is used to calculate the mass or volume of a liquid or gas flowing through a pipe or flow measuring device. This formula is represented as:

Q = A x v

Where:

- Q is the flow rate (volume or mass per unit time), the unit of measurement can be m³/s, m³/h, L/s, GPM, ft³/h, etc.

- A is the cross-sectional area of the pipe or flow measuring device, the unit of measurement can be square meters (m²), square feet (ft²), etc.

- v is the velocity of the fluid or gas flow, the unit of measurement can be meters per second (m/s), feet per second (ft/s), etc.

To calculate the flow rate, first determine the cross-sectional area and the velocity of the fluid or gas flow. Typically, the flow velocity is measured using flow measuring devices such as flow sensors or flow meters.

Accurate Flow Rate Measurement and Common Measurement Methods

Accurate Flow Measurement Methods

To measure the flow rate of a fluid stream, there are various methods available depending on the conditions and requirements of the application. However, the main steps for measuring flow rate of a fluid stream include:

- Selecting the appropriate flow measurement device for the desired flow and measurement requirements of the application. Commonly used flow measurement devices include hydraulic flow meters, magnetic flow meters, ultrasonic flow meters, electromagnetic flow meters, and more.

- Installing the flow measurement device correctly and in the appropriate location to ensure accuracy and reliability of the measurement results.

- Performing flow rate measurement using suitable methods according to the selected device. Flow rate measurement can be done manually or automatically.

- Verifying and confirming the flow measurement results to ensure accuracy and reliability of the measured data.

- Recording the flow measurement data and storing them for future use and reference.

The flow measurement process can be conducted by measurement experts or flow measurement device manufacturers. However, many applications also allow users to perform flow rate measurements themselves using simple flow measurement devices. Nevertheless, self-performed flow rate measurement requires specialized knowledge and measurement experience. Therefore, if unsure about one’s abilities, users should seek advice and support from measurement experts.

Common Flow Measurement Methods

There are several flow measurement methods used in industrial and engineering applications. Below are some common flow measurement methods:

- Diameter and velocity measurement method: This method involves using devices to measure the diameter of the pipe and the velocity of the fluid or gas flowing through it. From there, the flow rate is calculated using the formula Q = A x v, where A is the cross-sectional area of the pipe and v is the flow velocity.

- Pressure measurement method: This method measures the force exerted by the fluid or gas as it flows through a pipe or flow measurement device. The flow rate is calculated based on the relationship between pressure and flow rate of the fluid or gas.

- Time measurement method: This method is based on the time it takes for a known volume of fluid or gas to pass through a measured section of a pipe. The flow rate is calculated by dividing the length of the pipe section by the time taken.

- Oscillation measurement method: This method uses oscillation devices to measure the frequency of oscillation caused by the fluid or gas flowing through a pipe or flow measurement device. The flow rate is then calculated using complex mathematical formulas.

- Magnetic measurement method: This method utilizes magnetic sensors to measure the flow rate of the fluid or gas. Magnetic sensors can measure parameters such as velocity, pressure, temperature, etc., and flow rate is calculated based on these measurements.

Each of the

above flow measurement methods has its advantages and limitations and is suitable for different applications.

Some modern flow measuring devices today

Currently, there are many modern flow measuring devices used in daily life, industrial applications, and scientific and technical fields:

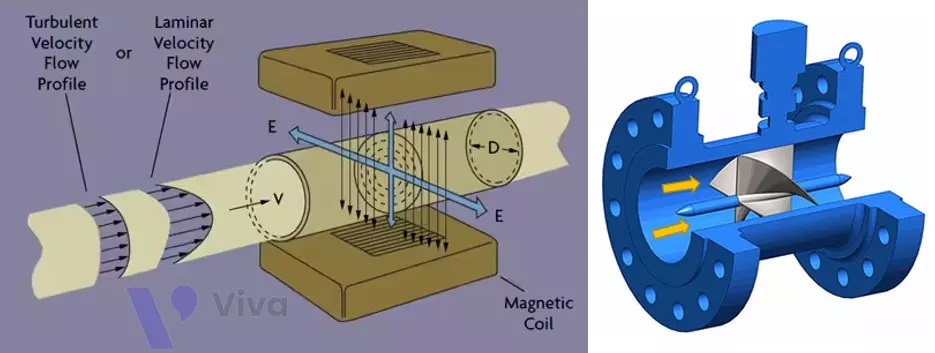

Electromagnetic flowmeter

The electromagnetic flowmeter uses the principle of flow interaction with a magnetic field to generate an electrical signal and measure the flow rate. This device is commonly used in flow measurement applications for liquids and gases.

Vortex flowmeter

The vortex flowmeter uses the principle of generating a vortex when the flow passes through a fan to measure the flow rate. This device is commonly used in flow measurement applications for liquids and gases.

Turbine flowmeter

The turbine flowmeter is a specialized flow measuring device used to measure the flow rate of air or steam in industrial applications. This device is designed with one or more rotating blades inside the measuring tube, directly connected to the turbine or can be installed separately.

Ultrasonic flowmeter

The ultrasonic flowmeter uses the principle of measuring the interaction of ultrasonic waves with the flow to measure the flow rate. This device is commonly used in flow measurement applications for liquids and gases.

Dynamic Flow Sensor

The dynamic flow sensor uses the principle of measuring the interaction between fluid flow and a counter to measure the flow rate. This device is commonly used in flow measurement applications for liquids.

Water Vapor Flow Sensor

The water vapor flow sensor uses the principle of measuring the interaction between fluid flow and a force sensor to measure the flow rate of water vapor. This device is commonly used in flow measurement applications for water vapor.

Mass Flow Sensor

The mass flow sensor uses the principle of measuring the interaction between fluid flow and a balance to measure the flow rate based on the mass of the flowing substance. This device is commonly used in flow measurement applications for liquids and gases.

These flow measurement devices have high accuracy and meet the flow measurement needs in modern industrial and scientific applications.

With the basic information about flow measurement provided in this article, you have a better understanding of this concept and common units of flow measurement. Additionally, through this article, you can also learn about the calculation and application of flow measurement in daily life and various industrial fields.