21H8KV120 Solenoid valve

Giá gốc là: 400.000 ₫.350.000 ₫Giá hiện tại là: 350.000 ₫.

Cập nhật lần cuối ngày 12/08/2025 lúc 04:51 chiều

Overview of 21H8KV120 Solenoid valve

The 21H8KV120 Solenoid valve belongs to the group of ODE Solenoid valves which are made of copper material with relatively small dimensions. According to the manufacturer’s specifications, this model has a size of dn15 or also known as 21mm diameter. With its outstanding operational capabilities, this product can be applied to various different systems, ensuring the best working efficiency.

The 21H8KV120 model is designed as a normally closed type, which is a commonly used design across systems nationwide. In the normally closed design, abbreviated as “Normal Open,” the product is always closed in its normal state. When power is supplied, the product switches to the open state.

See more about Solenoid Valve 21X3KT190

Operating Mechanism of 21H8KV120 Solenoid valve

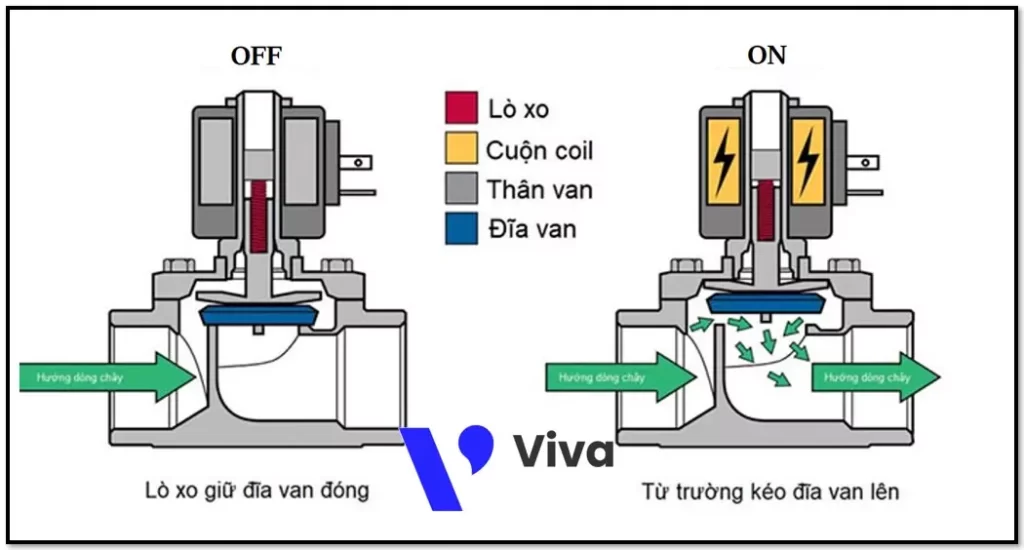

Regarding the operating mechanism of the 21H8KV120 Solenoid valve, it is relatively simple. The most important task for the operator is to switch on the remote switch to supply electrical energy to the specific component, which is the coil winding.

At this point, a magnetic field is generated inside the coil, pulling the valve stem upward. Simultaneously, the diaphragm in the lower part is also lifted, allowing flow to pass from one end to the other. When you turn off the power supply, preventing it from reaching the device, the elastic force of the spring will push the valve stem back to its original position, which is the closed state, blocking flow from passing through.

Based on the information shared above, it can be seen that the operation of Solenoid valves is relatively simple, requiring less time and effort compared to mechanical valves available in the market.

The 21H8KV120 Solenoid Valve with High Durability

As you may know, the 21H8KV120 solenoid valve is a product line made primarily from copper material, especially the body part. Copper is always regarded as a material with good heat and pressure resistance. Moreover, copper is resistant to corrosion in water systems and outdoor weather conditions. This is evident in products such as copper check valves, copper Y strainers, and copper ball valves, which are commonly preferred for basic water supply systems or systems with high temperature and pressure.

In addition to copper material, the coil winding is also a component that contributes to the improved durability of the product. Among the parts of a solenoid valve, the coil winding is the most vulnerable during long-term usage. To address this issue, the brand ODE solenoid valves has introduced the coil winding in the form of a cast coil. This enhances the product’s working capability and heat resistance, minimizing the risk of coil damage or overheating.

Considerations When Using the 21H8KV120 Solenoid Valve

The 21H8KV120 solenoid valve is a product line with a relatively small size and the valve body is not designed to be spacious like modern two-way valves. Therefore, when using this product, you need to pay attention to the following:

Avoid any hard objects impacting the diaphragm of the solenoid valve, as it can cause debris on the diaphragm or hinder the proper opening and closing of the solenoid valve.

Use the product in the appropriate working environment and avoid using it in environments with high corrosion.

Install the product correctly with the right flow direction to prevent any installation mistakes. The manufacturer will indicate the flow direction with an arrow on the body of the solenoid valve.

Use the product according to the specified parameters provided by the manufacturer, especially regarding pressure and voltage requirements.

Learn more: 21H9KV180 Solenoid Valve

ĐÁNH GIÁ SẢN PHẨM

Đánh giá

Chưa có đánh giá nào.