Pneumatic clamp cylinder

Giá gốc là: 130.000 ₫.90.000 ₫Giá hiện tại là: 90.000 ₫.

Cập nhật lần cuối ngày 12/09/2025 lúc 03:09 chiều

Pneumatic clamp cylinders are widely used in compressed air systems, particularly in highly automated systems, and are applied in manufacturing tasks.

So what is a pneumatic clamp cylinder, and how does it function, operate, and structure? Let’s explore in today’s article with VIVA.

Understanding pneumatic clamp cylinders

A pneumatic clamp cylinder, also known as a clamping pneumatic cylinder or pneumatic gripper, is a mechanical device that utilizes compressed air pressure to generate motion. It is designed in the form of a clamp that can open and close to grip specific objects.

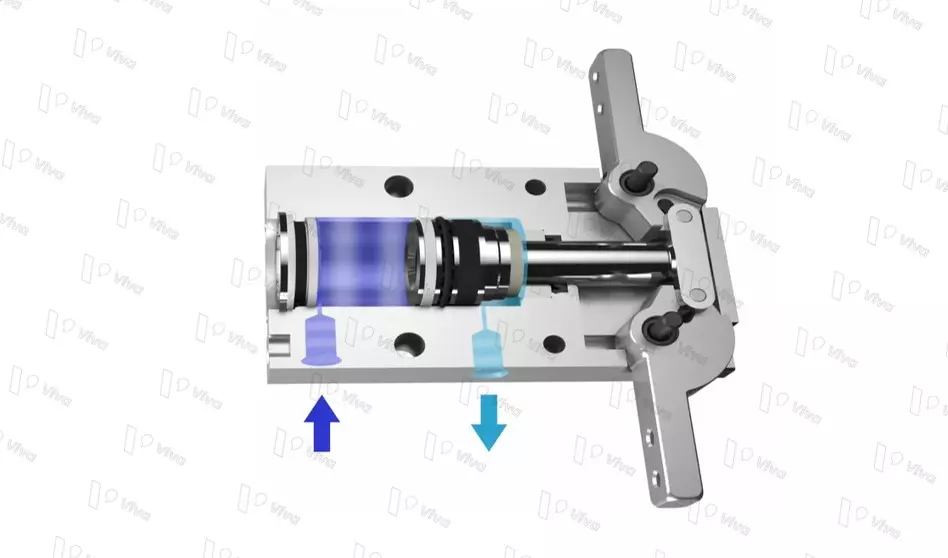

The operation of a pneumatic clamp cylinder involves the use of compressed air (typically stored in pressure tanks) that is supplied into the cylinder through air conduits. When the compressed air is introduced into the inner part of the cylinder, the pressure increases and pushes the piston to move in either an upward or downward direction. This translational motion of the piston is transmitted through a special internal drive mechanism within the cylinder, simultaneously transforming into the clamping motion of the two gripping bars at the cylinder’s head.

This device simulates the gripping action performed by humans, so it is usually not used independently but rather combined with various types of equipment or mechanisms. It can be mounted on pneumatic slide rails, robot arms, and various other motion mechanisms to transport objects from one position to another.

Structure and operation of pneumatic clamp cylinders

Structure of pneumatic clamp cylinders

Prior to the general development trend, pneumatic clamp cylinders are similar to other pneumatic devices. They are supplied not with just a single type but, over time, more and more new variations are being invented to optimize their performance in specific working conditions.

Each type of clamp cylinder has its own distinctive structure. Here, we will explore the structure of the most commonly used type, which is the two-bar clamp.

Pneumatic clamp cylinders are constructed from the following main components:

- Cylinder Body: The body is made of aluminum alloy, commonly in a rectangular box shape. The cylinder body typically has two air supply ports arranged at the corresponding ends. It also includes additional bolt holes for device connection, providing flexibility and convenience.

- Piston: This component withstands the pressure from the compressed air. When the pressure is sufficient, the piston moves along the cylinder body. Aluminum alloy is commonly used to manufacture the piston.

- Shaft: Made of stainless steel, one end of the shaft connects to the piston, and the other end connects to the drive mechanism.

- Bottom Cap: It is a combination of various parts such as a metal cap, rubber gasket, and retaining ring. Their purpose is to seal and complete the device.

- Drive Mechanism: The drive mechanism consists of pins, transmission bars, etc. All these components are made of stainless steel to ensure their strength during operation.

- Gripping Bar Positioning Shaft: These two components are used to limit the movements of the gripping bars. They allow the bars to rotate around themselves. Both components are made of stainless steel.

- Gripping Bars: Consisting of two symmetrically arranged parts, these bars are made of aluminum alloy.

The above is the complete basic structure of a pneumatic clamp cylinder. In addition to the main components mentioned above, several other auxiliary parts such as bolts, friction reducers, and shaft bearings are required to form a complete device. The quantity of these auxiliary components may vary depending on the specific type.

Operation of pneumatic clamp cylinders

As you may already know, pneumatic clamp cylinders function to securely hold objects through the clamping action of the two gripping bars designed on the cylinder. The process unfolds as follows:

- Compressed air intake: Initially, compressed air from the air supply source is delivered into the cylinder through an air hose and controlled by a pneumatic valve. The compressed air enters the cylinder body, increasing the pressure inside this component, thereby exerting force on the piston.

- Piston movement: The pressure of the compressed air inside the cylinder creates a thrust force acting on the piston. The magnitude of this force is determined by the “compressed air pressure” multiplied by the “piston face area.” As the piston moves, it pulls the valve shaft and subsequently the drive mechanism, causing the two gripping bars to close.

- Release of the clamp: The process of releasing the clamp begins when we change the position of the compressed air supply port. At this point, the compressed air pressure in the front chamber gradually becomes higher than that in the rear chamber. When this difference is significant enough, it pushes the piston to move backward, thus gradually opening the gripping bars.

- Complete opening of the clamp: Maintaining the position of the air supply port, the piston continues to move backward until it reaches the end of its stroke. At this point, the gripping bars are fully opened, with maximum clearance. This marks the completion of one working cycle of the pneumatic clamp cylinder.

This process repeats when the compressed air pressure is controlled, thereby precisely controlling the position and clamping force. The controller, through valves and sensors, can adjust the compressed air flow and pressure to meet specific requirements of the production process or application.

Classification of pneumatic clamping cylinders

Two-way pneumatic clamping cylinder

The two-way pneumatic clamping cylinder, also known as the two-rod pneumatic clamping cylinder, is a commonly used type of pneumatic cylinder due to its simple structure, stable operation, and suitability for objects with box-like shapes. It is also a common shape for various products found in manufacturing plants.

Therefore, this type of device is more widely used. The two-way pneumatic clamping cylinder comes with various options in terms of clamp size and cylinder body size.

Three-way pneumatic clamping cylinder

The three-way pneumatic clamping cylinder is designed with three clamping jaws, evenly spaced at 120° angles. During operation, these jaws simultaneously open or close to perform the function of securely holding an object in place.

With its unique design, this type of device is suitable for objects with a shape similar to a cylindrical form. However, in practical applications, this shape is less common compared to box-like shapes. Therefore, three-way pneumatic clamping cylinders with clamping jaws are less commonly used compared to the two-way design.

Advantages and disadvantages of pneumatic clamping cylinders

Advantages

As a widely used device in various fields, pneumatic clamping cylinders significantly contribute to automation in manufacturing. When compared to devices that use direct force for clamping, pneumatic clamping cylinders offer several superior advantages:

- The cylinder operates accurately and stably under various working conditions.

- Factors such as clamping force, clamping speed, and cylinder stroke can be controlled and regulated.

- The device provides continuous high-intensity operation and requires minimal maintenance and repairs.

- It offers high flexibility for easy integration with different components and mechanisms, as it is designed to be installed in various orientations.

- It is widely available in the market, making it easy to purchase for new projects or replacements for outdated equipment. Furthermore, these products are relatively affordable, allowing users easy access.

Disadvantages

Despite being highly regarded for its numerous advantages, pneumatic clamping cylinders also have certain limitations. We aim to provide this information to customers so that they have a comprehensive understanding of the product.

Common limitations of many types of pneumatic clamping cylinders include:

- The clamping force of the device can be adjusted by changing the compressed air pressure used to operate it. However, the compressed air pressure supplied to the cylinder is typically limited to a range of 1.5 to 7 bar. Increasing the clamping force often requires increasing the diameter of the piston, which can be impractical in many cases as it may alter the overall structure of the initially designed system.

- Each device has a specific clamping range limitation. This disadvantage can be partially overcome by adding extended clamping bars to the device.

- A pneumatic system that meets the required specifications, including air supply capacity and appropriate air pressure, is needed to operate the device. This implies the need for a relatively complex system to provide power for the functioning of the air compressor.

- The operation of the device produces considerable noise, especially with large-scale systems and a high number of devices. The resulting sound can resonate and have negative effects on individuals.

VIVA provides pneumatic clamping cylinders nationwide

The pneumatic clamping cylinders are supplied with a variety of options at VIVA. We directly import all these devices from various brands, including CKD and SMC from Japan, Airtac from Taiwan, and Festo from Germany.

Common piston diameter sizes range from 6 mm, 10 mm, to 40 mm, and there are also many other devices designed with special sizes.

There is a diverse range of options for manual clamping configurations, with a range starting from 3mm and capable of meeting almost all typical industrial applications.

The devices are manufactured from high-quality materials, allowing them to operate continuously for a long time under the influence of high-pressure compressed air.

All of our products are offered at very reasonable prices and are supported with nationwide delivery.

Above are important pieces of information related to pneumatic clamping cylinders, compiled by the VIVA team, with the aim of providing customers with a comprehensive overview. We are pleased that this article can help answer some questions related to pneumatic clamping cylinders.

See more products compact pneumatic cylinders.

Chưa có bình luận nào

Đánh giá Pneumatic clamp cylinder

Chưa có đánh giá nào.