Differential pressure flow meter

Giá gốc là: 13.000.000 ₫.11.990.000 ₫Giá hiện tại là: 11.990.000 ₫.

Cập nhật lần cuối ngày 29/07/2023 lúc 05:39 chiều

In many industrial systems involving fluids, monitoring and testing pressure, temperature, and flow rate are crucial. Differential pressure flow meters are specifically designed to provide flow measurement solutions within the pipeline system.

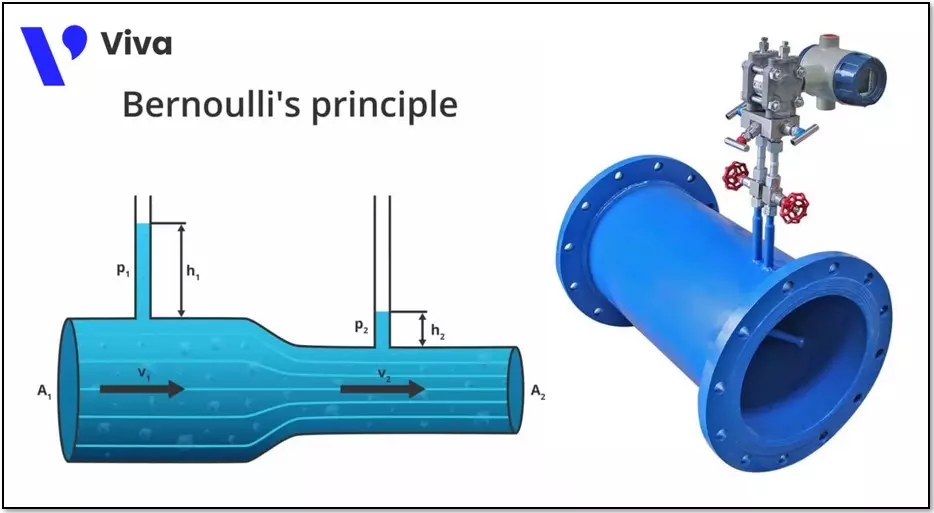

By applying Bernoulli’s law, these devices are considered reliable for flow measurement of various types of fluids, as they evaluate the flow rate based on pressure differentials.

In this article, we will explore useful knowledge related to this type of flow meter.

Understanding Differential Pressure Flow Meters

Differential pressure flow meters, also known as differential pressure flow gauges or differential pressure flow transmitters, are a type of flow meter that operates based on Bernoulli’s law.

They can be used to measure the flow rate of various fluids, including gases, liquids, and hot vapors. This is achieved by evaluating the pressure difference between two different positions within the flow. The pressure differential is generated by either changing the pipe’s cross-sectional area or introducing a specially designed element into the pipe.

The pressure difference between these two points is directly proportional to the velocity of the flow.

Bernoulli’s Law Applied in Differential Pressure Flow Meters

Bernoulli’s law is a physical law that describes the relationship between the pressure of a fluid and its velocity as it flows through a narrow region within a pipe. This law is named after the Swiss physicist Daniel Bernoulli, who discovered it in the 18th century.

Bernoulli’s law states that the pressure of a fluid decreases as its velocity increases, and conversely, the pressure of a fluid increases as its velocity decreases.

This means that when a fluid flows through a narrow region in a pipe, its velocity increases, and therefore its pressure decreases. Similarly, when a fluid flows through a wider region in a pipe, its velocity decreases, and therefore its pressure increases.

Development History of Differential Pressure Flow Meters

The need for flow measurement has long been recognized in both practical applications and research calculations. Many types of flow meters have been studied and developed, including differential pressure flow meters.

There have been various types of flow measurement devices based on pressure differential, but the prototypes similar to the current differential pressure flow meters were developed in the early 20th century.

When introduced into practical use, these devices have been continuously improved and refined, integrating new technologies and features, resulting in different variations. However, all these devices operate based on Bernoulli’s law.

In recent years, other flow measurement technologies such as electromagnetic and ultrasonic flow meters have been developed. Nevertheless, differential pressure flow meters remain an important tool for measuring flow velocity of fluids in various applications, ranging from scientific and industrial to environmental.

Technical Specifications of Differential Pressure Flow Meters

Differential pressure flow meters are available in various types and the technical specifications of the devices will vary depending on the specific product. Based on the technical specifications, we can make a preliminary assessment of whether the device is suitable for the system that needs to be measured.

Below are the basic technical specifications compiled from various types of differential pressure flow meters.

- Optional working pressure range: 8 bar, 10 bar, 16 bar, 20 bar, etc.

- Working temperature range: -90℃ to 400℃

- Measurement accuracy: 0.5%, 1%, 1.5%, etc.

- Material for the body part of the flow meter: Stainless steel.

- Operating power supply: 24V DC, 220V AC

- Origin: USA, Japan, Taiwan, etc.

- Product warranty period: 12, 16, or 18 months (depending on the product).

Structure of Differential Pressure Flow Meters

As you already know, the detailed structure of differential pressure flow meters may have slight differences between different types and manufacturers. However, because they operate based on the same principle, the basic structure remains unchanged.

The structure of a differential pressure flow meter includes the following components:

- Restriction element: This component creates flow restriction and generates a pressure differential between two points along the conduit. Several main devices are used in differential pressure flow meters, including orifice plates, Venturi tubes, Pitot tubes, and nozzle flow meters.

- Pressure differential transmitter: This component converts the pressure differential signal between two points along the conduit into an electrical signal. This is often achieved using a pressure differential transmitter, such as a pair of pressure sensors or a multipoint pressure sensor.

- Flow reading unit: The flow reading unit receives the electrical signal from the pressure differential transmitter and calculates the flow rate based on that signal combined with initial calibration parameters. After processing the received information, the final value of the flow rate is transmitted to the display on the flow meter or to a remote monitoring device.

- Accessories: Additional components such as valves, conduits, and fittings are required to connect the restriction element, pressure differential transmitter, and flow reading unit together in a complete flow measurement system.

Overall, differential pressure flow meters operate based on measuring the pressure differential between two points along the conduit, which is proportional to the flow rate of the fluid flowing through the conduit.

Operation of Differential Pressure Flow Meters

A differential pressure flow meter is a device used to measure the flow rate of liquids or gases in pipes. Its operation is based on the Bernoulli principle and the Venturi effect.

The Bernoulli principle states that the pressure of a fluid decreases as its flow velocity increases, and vice versa. The Venturi effect is the phenomenon of pressure reduction in a pipe when a fluid or gas flows through a narrow constriction.

Differential pressure flow meters utilize two pressure sensors to measure the pressure difference between two points in the pipe: one before and one after the fluid or gas passes through a narrow constriction (or a specially designed element that creates a pressure difference as the flow passes through it). As the fluid or gas flows through the constriction, the flow velocity increases, resulting in a pressure drop at the constriction point.

The pressure sensors at the upstream and downstream points of the constriction measure the pressure difference between these two points. Through calculations, the flow meter determines the flow rate of the liquid or gas passing through the pipe.

Characteristics of Differential Pressure Flow Meters

Advantages of Differential Pressure Flow Meters

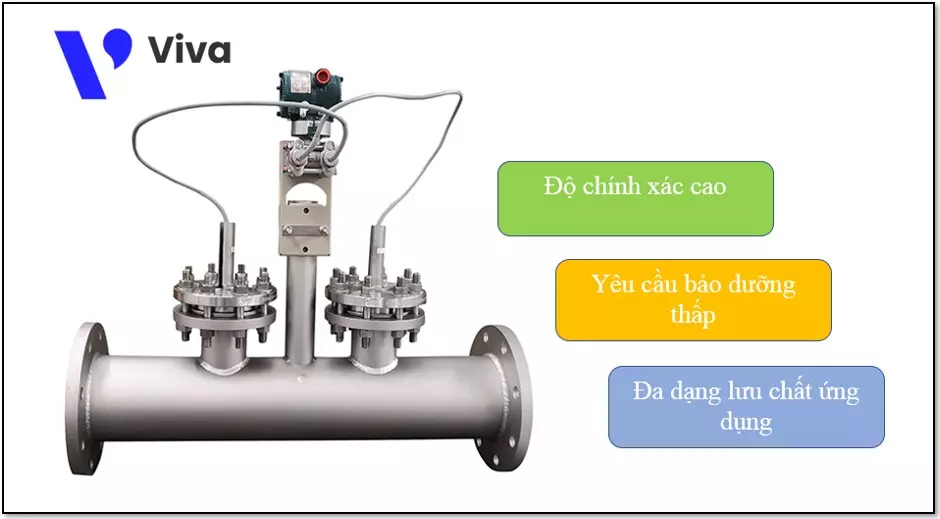

Provides reliable flow measurement solution with high accuracy: The device is evaluated by engineers and technicians to have the capability to measure flow rates with high accuracy, regardless of challenging operating conditions, such as fluctuating flow regimes.

Low maintenance requirements: Due to its design characteristics, the device does not utilize moving elements to sense the flow velocity, which limits the adverse effects of flow on the meter and results in low maintenance requirements.

Optimization capability for working systems: The device is designed to be able to meet various working conditions, and with the adjustment buttons, we can reset the input parameters to facilitate calculations.

Limitations of Differential Pressure Flow Meters

Limited use for fluids containing impurities: Due to the utilization of pressure differentials between two positions in the pipe, measured through pressure sensor membranes, the differential pressure flow meter is designed with fluid pathways leading to these sensor membranes. If it operates with fluids containing impurities over an extended period, sedimentation can clog these pathways.

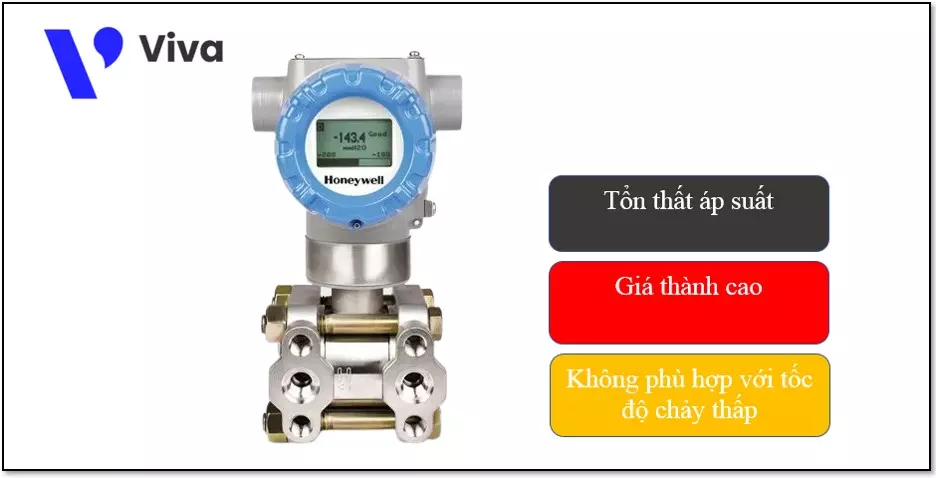

Pressure loss: Although the device does not employ directly contacting moving components with the fluid to sense flow velocity, it requires a pressure generation component. In practical working conditions, this component is placed within the flow of the fluid and causes a certain level of obstruction to the fluid flow.

High cost: The device has a relatively complex structure with many intricately manufactured components made of materials with good mechanical properties, combined with electronic components. These factors contribute to the relatively high cost of differential pressure flow meters.

Limited applicability in systems with low flow velocities: They are not suitable for use in pipe systems where the flow velocity is low, as they often fail to generate a significant pressure differential and maintain stability for flow measurement.

Applications of Differential Pressure Flow Meters

These flow meters are designed to provide solutions for measuring flow rates of various fluids used within industrial systems, combined with features such as temperature and pressure measurement capabilities. Different types of devices have been developed to meet increasingly stringent requirements for the automatic operation of systems.

Some examples of the applications of differential pressure flow meters include:

- HVAC systems: These devices are commonly used in heating, ventilation, and air conditioning (HVAC) systems to measure the flow rate of air, as well as fluids such as chilled water, hot water, and steam. They help ensure that the system is operating efficiently.

- Chemical processing: Differential pressure flow meters are used in the chemical processing industry to measure the flow rates of different liquids in various production stages, such as acids, bases, and solvents. Accurate flow measurement in these systems is crucial as it affects the mixing ratio of components.

- Oil and gas industry: These devices are widely used in the oil and gas industry, along with other types of flow meters, to measure the flow rates of crude oil, natural gas, refined products, and more. They are essential for accurately measuring production rates and evaluating the overall system performance, as well as supporting control and adjustment of input material processes (both liquids and gases).

- Water treatment: These devices are used in water treatment plants to measure the flow rates of water and other liquids. They help ensure that the treatment processes are operating efficiently and that the correct amounts of chemicals and other additives are being added to the water.

Support and Consultation for Differential Pressure Flow Meters

Differential pressure flow meters are recognized as devices that provide highly accurate flow measurement solutions, capable of working stably in various conditions and suitable for different types of fluids.

However, like other types of flow meters, these devices cannot measure the flow rate of all working fluids. Additionally, the installation, maintenance, and calibration processes should be carried out according to the manufacturer’s recommendations.

Understanding this, as a product supplier, we take responsibility for providing technical advice related to the equipment and supporting customers in finding products that meet their technical requirements and desired features.

To have a more specific discussion about our products, we encourage you to contact us directly via phone or email. If feasible, we warmly welcome you to visit our company, allowing us to have a detailed conversation about the products.

See more products: ultrasonic flow meters.

ĐÁNH GIÁ SẢN PHẨM

Đánh giá

Chưa có đánh giá nào.