Pneumatic silencer

Giá gốc là: 5.000 ₫.4.000 ₫Giá hiện tại là: 4.000 ₫.

Cập nhật lần cuối ngày 09/08/2023 lúc 04:08 chiều

Pneumatic silencer is a pneumatic device used to reduce the noise of compressed air systems during operation. They function to reduce the level of noise pollution for the surrounding environment. In this article, we will learn more about pneumatic mufflers, their operating mechanisms and practical applications.

What is a pneumatic silencer?

A pneumatic silencer, also known as a pneumatic noise reduction device or pneumatic muffler, is a device used to reduce noise in compressed air systems. These devices are typically installed in industrial applications such as air compressors, compressed air pipelines, and certain types of pneumatic valves.

The operating mechanism of a pneumatic silencer is to reduce the noise generated by compressed air during the air release process. This is achieved by directing the air through various filters and different silencer components, thereby lowering the air velocity and reducing pressure and noise.

Pneumatic silencers are commonly manufactured using materials such as plastic, bronze, or stainless steel.

Different types of pneumatic silencers can be used depending on the requirements of the compressed air system and the desired noise reduction level. Some examples include fixed silencers, adjustable silencers, and hexagonal silencers.

Depending on the application requirements, these devices can be installed individually or combined with other equipment to form a complete system.

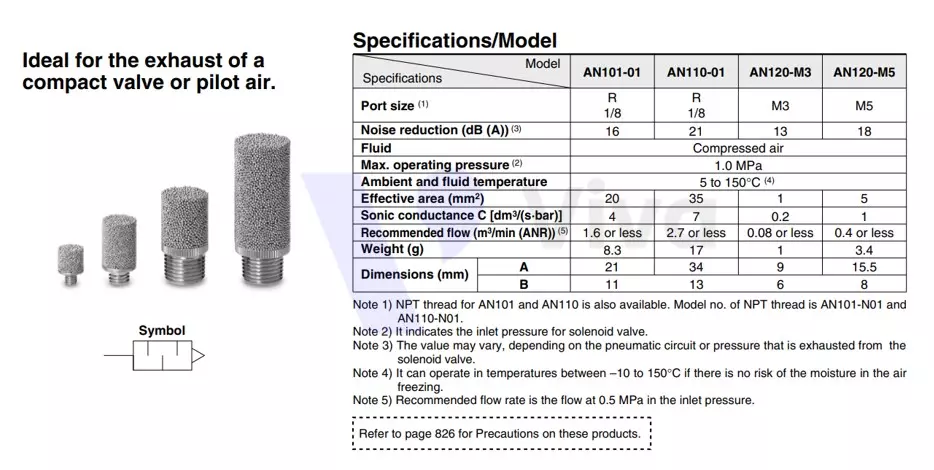

Technical Specifications of Pneumatic Silencers

To have a better understanding of pneumatic silencers and determine whether they are suitable for your existing compressed air system, customers are often interested in the product’s technical specifications. As a product line offered in various types, each type is designed with specific parameters.

However, if you are looking for a general overview of these devices, you can refer to the following compilation of basic technical specifications for pneumatic silencers:

- Working Fluid: Compressed air

- Mounting Type: Threaded

- Thread Sizes: 1/8″, 1/4″, 3/8″,…

- Thread Lengths: 7mm, 10mm, 12mm,…

- Options for Construction Materials: Plastic, bronze, aluminum alloy, stainless steel,…

- Common Working Pressure Range: 10 bar

- Operating Temperature Range: -20℃ to 70℃

- Noise Reduction Level: Approximately 30 dB

- Air Flow Rate Through the Device: From 0 to 0.8 m³/min, 1.2 m³/min, 4.5 m³/min,…

- Manufacturers: Airtac – Taiwan, Parker – USA, Festo – Germany,…

Basic Structure of Pneumatic Silencers

Similar to other compressed air devices, pneumatic silencers come in different shapes and functions, which results in certain differences in their structures.

In this article, we will explore the structure of the basic type of pneumatic silencer, which is also the most commonly used type. These devices consist of two main components:

Sound-reducing head: The sound-reducing head has a special structure and can be made from materials such as plastic, bronze, or red brass. It is composed of many small-sized particles that are intricately woven together using special techniques. Once this component is manufactured, it forms numerous tiny passages for the compressed air, which significantly reduces pressure and noise during the air release process.

Connecting thread: This component serves to connect the pneumatic silencer to the working system. The connecting thread can be a pipe thread (NPT), metric thread (M), or taper thread (R). It can be made from materials such as plastic, bronze, or stainless steel.

Classification of Pneumatic Silencers

Adjustable Pneumatic Silencers

For pneumatic silencers that can be adjusted, an adjustable screw component is designed at the sound-reducing head. With this design, the pneumatic silencer functions similarly to a flow control valve. With such a special structure, the device can regulate the amount of compressed air released into the environment while also reducing noise.

Hexagonal Pneumatic Silencers

Hexagonal pneumatic silencers have the advantage of compactness, making them suitable for installation in space-limited locations.

The hexagonal shape is manufactured according to standard specifications, making installation very easy.

Stainless Steel Pneumatic Silencers

These devices are made entirely of stainless steel. They take advantage of the material properties of stainless steel, such as superior durability, corrosion resistance, and resistance to oxidation. However, to achieve these advantages, the devices tend to have a relatively higher cost, so they are typically used in specific working conditions.

Brass Pneumatic Silencers

Brass pneumatic silencers are devices made from brass, an alloy of copper. This material is commonly used in various industrial applications. Brass has advantages similar to stainless steel in terms of corrosion resistance. However, brass tends to have lower resistance to corrosion, heat, and mechanical stress compared to stainless steel (depending on the specific type of stainless steel).

Due to these reasons, brass pneumatic silencers are more affordable and widely used.

Plastic Pneumatic Silencers

These devices are made entirely of plastic, making them easier to process compared to products made of brass or stainless steel. Additionally, this material is not susceptible to chemical corrosion or oxidation. One significant advantage is that these products are cost-effective, so they are widely used in various systems.

The limitation of this product line is that they cannot withstand high-temperature and high-pressure working conditions.

Some Considerations for Choosing Pneumatic Silencers

With many years of experience in supplying industrial equipment and interacting with numerous customers and systems, we understand that selecting a suitable pneumatic silencer is not an easy task, but it is also not overly challenging.

To choose the right pneumatic silencer that meets technical and quality requirements while balancing the cost, it is important to consider the following issues:

- Functionality: There are various types of pneumatic silencers available on the market. In addition to their main function of reducing noise generated during air discharge, some products also integrate the feature of regulating the airflow.

- Size and thread type: The size and thread type of the pneumatic silencer must be compatible with the installation equipment. Pay attention to internal threads, external threads, and design standards.

- Working pressure: Selecting a device capable of withstanding the working pressure of the pneumatic system is crucial.

- Flow rate: Each system has different air discharge flow rates. The pneumatic silencer, located at the end of the system and being the final device in contact with compressed air, must allow sufficient airflow.

- Material composition: The choice of material for manufacturing the device should be based on the practical environmental conditions. If the system operates at high temperatures, metal or alloy devices should be selected. If the working environment is corrosive, plastic is an optimal choice.

These are some considerations in selecting the appropriate pneumatic silencer. We hope they will be helpful to our valued customers.

Pneumatic Silencers at VIVA Company

Pneumatic systems are widely used in various fields, especially in the industrial sector. In industrial-scale operations, the process of discharging compressed air to the outside cannot be avoided, and this action often generates significant noise.

The noise can directly affect the health of nearby operators or create difficulties in communication and work exchanges. To overcome this drawback of pneumatic systems, pneumatic silencers are installed at the air discharge points of various devices.

Currently, we offer a wide range of pneumatic silencer products, with various options in terms of types and sizes.

At VIVA, all our products are guaranteed to be genuine and provided to the market at the most competitive prices.

For more product options, you can check out our pneumatic directional valves.

ĐÁNH GIÁ SẢN PHẨM

Đánh giá

Chưa có đánh giá nào.