Ultrasonic Flow Meter

Giá gốc là: 10.000.000 ₫.9.000.000 ₫Giá hiện tại là: 9.000.000 ₫.

Cập nhật lần cuối ngày 29/07/2023 lúc 05:56 chiều

Ultrasonic flow meters, known as flow measuring devices, have many outstanding advantages such as: non-contact with the fluid, high accuracy in measurement, and versatile applications. It is because of these features that they can be applied to measure the flow rate of various systems.

In this article, we will explore useful information about this type of flow measuring instrument.

Introduction to Ultrasonic Flow Meters

Ultrasonic flow meters are a type of flow meter used to measure the flow rate of a liquid by utilizing ultrasonic waves.

Based on the operating principle, ultrasonic flow meters can be divided into two types: those operating based on time difference and those operating based on frequency change.

These flow meters work by emitting high-frequency sound waves (ultrasonic waves) into the liquid. These waves pass through the fluid and reflect back from particles, air bubbles, or other substances with different properties in the flow. These substances cause a change in the frequency of the emitted sound waves, which is then used to calculate the velocity of the flow.

The velocity of the wave is influenced by the velocity of the fluid and the difference in time taken for the wave to travel from the “transmitting end” to the “receiving end.” This difference is used to calculate the flow rate of the liquid.

This device operates by emitting high-frequency sound waves to measure the flow rate of the fluid. Therefore, it is considered a non-intrusive type of flow meter, ensuring that the measurement process does not affect the working fluid inside the system. Additionally, this enhances the durability of the measurement device.

In addition to the name “ultrasonic flow meter,” this device is also known as an ultrasonic flow gauge and is called Ultrasonic Flow Meters in English.

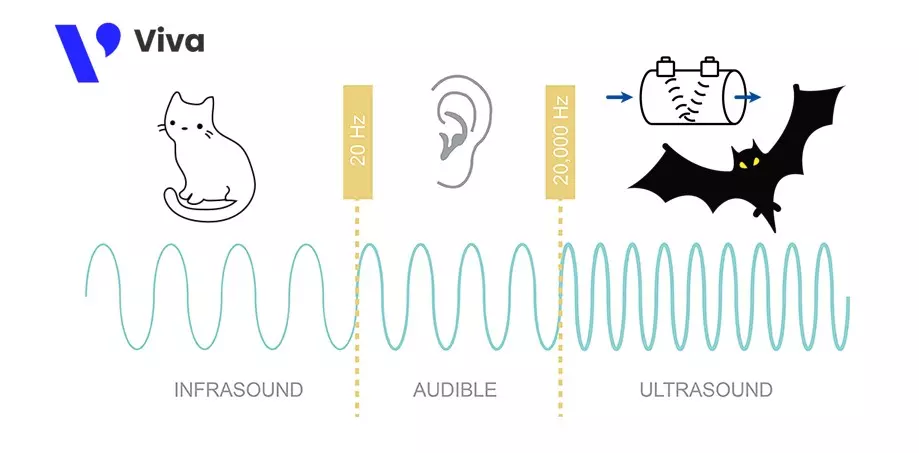

Ultrasonic Waves

Ultrasonic waves are sound waves with a frequency higher than the upper limit of human hearing, which means frequencies above 20 kHz.

Ultrasonic waves are generated using ultrasonic transmitters, which can emit waves of different frequencies. They are used in various fields, including medicine, industry, science, and technology.

Ultrasonic waves are applied in many different fields due to their characteristics, such as:

- Ability to penetrate various materials: Ultrasonic waves can penetrate materials such as metal, ceramics, and glass, making detection, testing, and processing more effective.

- Reflection ability: Ultrasonic waves have good reflection capabilities from different materials, enhancing accuracy in detection and measurement.

- Wave propagation speed: Ultrasonic waves propagate faster than regular sound waves in gaseous environments and slower in liquid environments.

And many other characteristics.

Development History

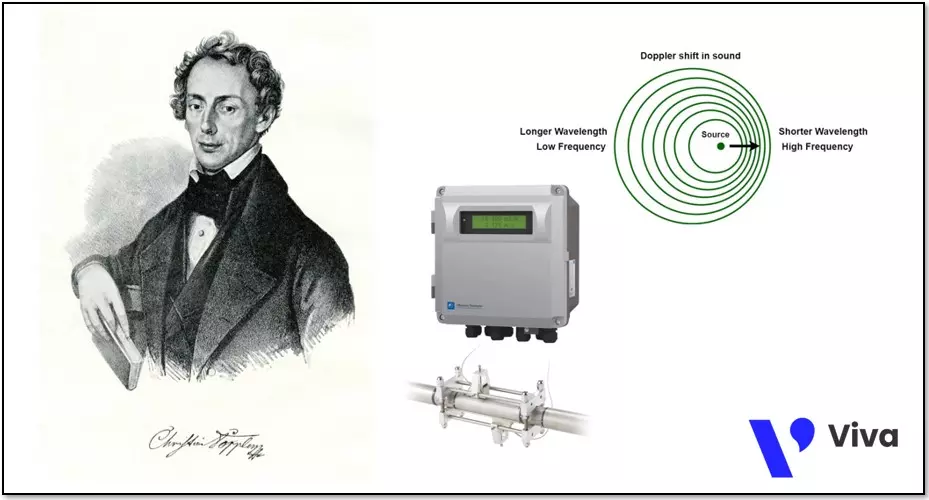

In 1842, Austrian physicist Christian Doppler discovered that when a sound source approaches a stationary observer, the wavelength becomes shorter, and conversely, when the sound source moves away, the wavelength becomes longer.

The most noticeable example of this phenomenon is when we stand beside a road and a car with a honking horn passes by. Although the frequency of the horn’s sound remains constant, we still perceive a difference in the frequency of the emitted sound.

From that observation, this phenomenon was named the Doppler effect.

The Doppler effect applies to ultrasonic waves in ultrasonic flow meters. When ultrasonic waves are emitted, they are influenced by the moving fluid or gas in the pipeline, causing a change in the wave frequency. The receivers then receive ultrasonic waves with different frequencies than the original frequency, and by calculating this difference, ultrasonic flow meters can determine the flow rate of the fluid or gas in the pipeline.

In the 1950s and 1960s, scientists began researching the use of ultrasonic waves to measure fluid flow in tanks. However, the initial devices could only measure flow rate at a fixed location and couldn’t measure flow rate in pipelines.

In the 1970s, scientists developed ultrasonic flow meters capable of measuring flow rate in pipelines, which was a significant breakthrough in using ultrasonic waves for flow measurement. However, these devices were still expensive and not widely used in industries.

In the 1980s, flow meter manufacturers started developing compact, highly accurate, and affordable ultrasonic flow meters. Since then, they have been widely used in various industries and applications, ranging from water and environmental management to oil and gas and chemical industries.

Currently, new technologies such as non-contact ultrasonic flow meters or the integration with the Internet of Things (IoT) are being researched and developed, aiming to enhance the accuracy and applicability of ultrasonic flow meters.

Technical Specifications

Due to the availability of various types, specific technical specifications may vary for each type of flow meter. Here, I will provide a summary of the basic technical specifications for some popular ultrasonic flow meters to give customers a general overview of this type of flow meter.

- Flow measurement range: Up to 100,000 m³/h

- Flow measurement accuracy: Fluctuates below 1%, 1.5%

- Operating temperature range: From -40℃ to 250℃

- Operating pressure range: Up to 10,000 psi

- Sound wave frequency: From 100 kHz to 2 MHz

- Power supply: From 100 ~ 220V/AC; 20 ~ 36V/DC

- Casing material: Stainless steel, plastic, aluminum, etc.

- Water resistance standards: IP65, IP67

- Manufacturer: Omega – USA

- Warranty policy: 12, 16, or 18 months (depending on the product type)

Basic Structure of Ultrasonic Flow Meter

Ultrasonic flow meters are modern flow measurement devices equipped with many useful features and various flow measurement modes. Therefore, these devices have a complex structure consisting of multiple electronic components combined with numerous details and parts.

Through years of application and improvement, ultrasonic flow meters have developed into different variants, although they share a common working principle. This leads to the detailed structure of the device depending on its type.

In the scope of this article, we will explore the general structure of this type of flow meter.

The ultrasonic flow meter is composed of the following main components:

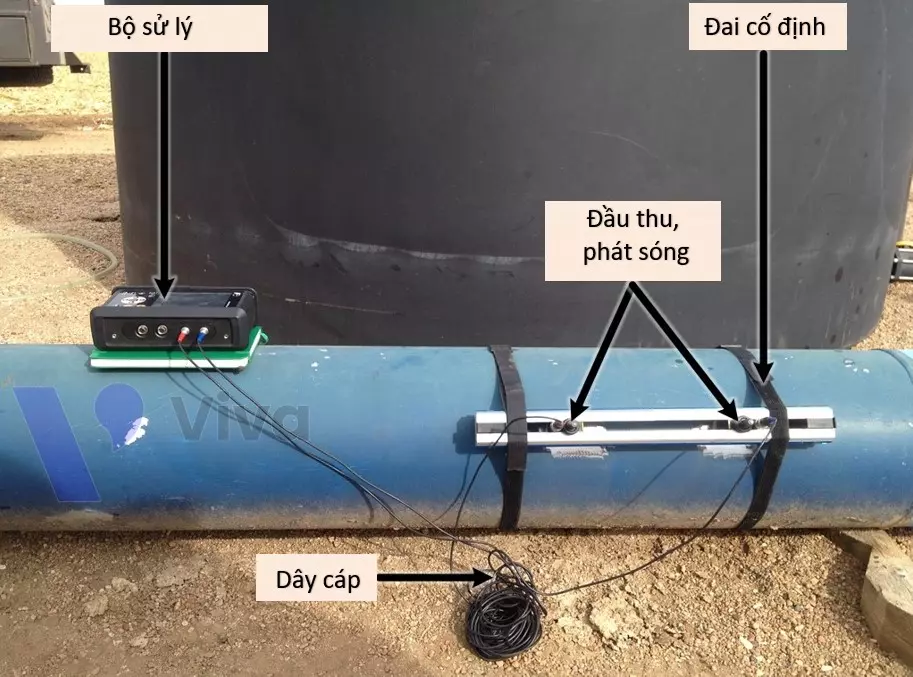

- Transducer: This component can be a pair of transducers or multiple pairs, depending on the manufacturer’s design. It includes an ultrasonic transmitter that emits sound waves through the flowing fluid and an ultrasonic receiver. The received signal is then transformed and transmitted to the processing unit.

- Processing Unit: This part receives the signals transmitted by the ultrasonic receiver. By combining them with the values set during the calibration process and the pre-programmed algorithms, this unit performs analysis and calculations to provide appropriate flow measurements before transmitting them to the display screen.

- Display Screen: It shows the measured fluid flow rate and other related parameters during the measurement process.

- Auxiliary Components: These include components such as power supply, temperature sensors, connecting parts, and vibration dampers.

Classification of Ultrasonic Flow Meters

There are various criteria that can be used to classify ultrasonic flow meters, such as based on the brand, country of origin, or the type of working fluid. However, in this article, we will classify these devices based on their operating principles, specifically into two types: Doppler and Transit Time ultrasonic flow meters.

Doppler Ultrasonic Flow Meter

The Doppler Ultrasonic Flow Meter operates based on the Doppler effect, which is why it is named as such.

The device uses an ultrasonic transmitter that emits sound waves into the flowing fluid inside the pipe. During normal operation, the fluid flow may contain impurities or generate air bubbles within the flow, which are collectively referred to as “suspended particles.”

When the sound waves travel through the fluid and encounter these suspended particles, they cause changes in the received frequency at the receiver (the velocity of these suspended particles is directly proportional to the frequency shift). Instead of measuring the velocity of the flow, this device measures the velocity of the discontinuity points within the flow. Then, in combination with pre-programmed algorithms in the device, it calculates the flow parameters that need to be measured.

The device performs effectively in flows with high levels of impurities such as mud, wastewater, and water, among others.

Transit Time Ultrasonic Flow Meter

The Transit Time Ultrasonic Flow Meter, as known in English, emits ultrasonic waves to measure the velocity of the flow by analyzing the time difference between the start of transmission at the transmitter and the start of reception at the receiver.

This time difference is proportional to the flow velocity. If the sound waves are transmitted in the same direction as the flow, the time difference decreases as the flow velocity increases.

In the second case, if the sound waves are transmitted in the opposite direction to the flow, the time difference increases and is also directly proportional to the flow velocity.

Various Variations in the Shape of Ultrasonic Flow Meters

Ultrasonic flow meters are available in different versions, produced over time by various manufacturers. Therefore, sometimes based on their appearance alone, it may not be immediately recognizable that they are flow meters utilizing ultrasonic waves.

Due to the requirements arising from practical working conditions and the non-contact measurement method with the fluid, ultrasonic flow meters are often designed to be detachable, not necessarily having a fixed pipe section, with the measuring system (although in some special cases, a fluid conduit component is still designed).

Regarding the ultrasonic transceiver, typically the device is designed with two transducers, corresponding to a receiving transducer and a transmitting transducer. However, there are also devices that integrate both the receiving and transmitting functions into a single transducer, and some devices are equipped with multiple transceivers.

Advantages and Disadvantages of Ultrasonic Flow Meters

Ultrasonic flow meters, known as one of the preferred types of flow measurement devices, provide a solution for measuring flow rates in various systems. However, like most other flow meters, ultrasonic flow meters also have their own advantages and disadvantages.

Let’s explore them in more detail to make an informed choice regarding the suitable flow meter for your system.

Advantages

The flow measurement device operates without direct contact with the fluid, ensuring stability in flow and minimizing pressure loss and flow restriction as it passes through the flow meter.

The absence of direct contact with the working fluid contributes to the device’s durability by eliminating the effects of mechanical stress and chemical corrosion from the fluid.

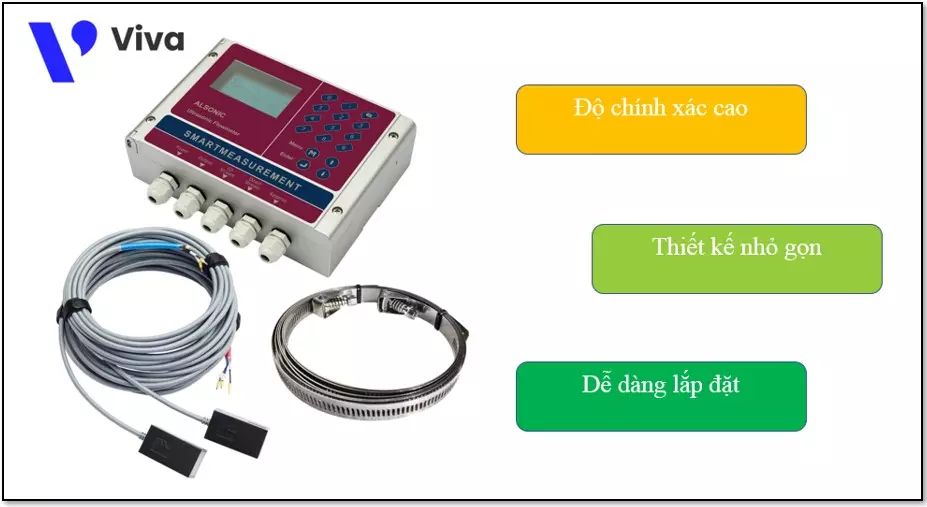

Most ultrasonic flow meters do not require the installation of flow conduits or pipes like conventional flow meters. Instead, they use clamp-on transducers that are fixed onto the pipe. This design allows for easy installation and removal of the device without interrupting the flow or directly interfering with the pipe.

The device provides the capability to measure the flow rate of various liquids and gases.

The device is known for its high accuracy in flow measurement.

Disadvantages

The main disadvantage of this device is the relatively high cost of investment.

The device is not suitable for measuring the flow of certain fluids that do not allow the transmission of ultrasonic waves. It can be challenging to measure the flow rate of liquids or gases that lack air bubbles or suspended particles to reflect the sound waves.

Practical Applications of Ultrasonic Flow Meters

Designed to measure the flow rate of fluids, ultrasonic flow meters utilize principles related to the transmission and reflection of ultrasonic waves, combined with the structural characteristics of the product. They are capable of being applied in various systems and can adapt well to different types of fluids.

Some examples of practical applications of ultrasonic flow meters include:

- In industrial settings, these devices are used in many industrial plants such as paper mills, chemical production plants, wastewater treatment plants, etc. With the ability to measure flow rates using high-frequency sound waves, these flow meters are suitable for working with fluids in these systems.

- They are used in oil extraction to measure the flow rate of crude oil, natural gas, and other fluids, ensuring accurate and stable operations in the process of extraction and crude oil refining.

- They are used for water flow testing inside pipelines, especially in large-sized pipes. Unlike many other types of flow meters that require direct installation in the pipeline, ultrasonic flow meters only need to have the transmitter and receiver fixed onto the pipe. Therefore, they are not significantly limited by the diameter of the pipe.

Maintenance and Calibration of Ultrasonic Flow Meters

Maintenance and calibration of ultrasonic flow meters are necessary tasks to ensure that the devices are operating accurately and reliably in flow measurement.

The maintenance of these devices typically includes activities such as electronic circuit testing, sensor inspection and cleaning, computer testing and calibration, and ensuring that the measurement software is updated and functioning properly.

Calibration of ultrasonic flow meters should be performed when there are changes in the system’s working parameters, such as changes in the type of working fluid or changes in the pipeline.

The specific steps for calibrating ultrasonic flow meters may vary depending on the type of flow meter, but they usually involve using standards and benchmarks to compare with the measured data from the flow meter, combined with adjusting the parameters to ensure accurate operation.

Regular maintenance and calibration of ultrasonic flow meters are important to ensure that the provided measurement data is accurate and reliable.

Manufacturers typically provide instructions for the maintenance and calibration of their devices, and it is advisable to follow these guidelines to ensure that your device functions well and has high accuracy.

See more products mechanical water flow meters.

Đánh giá

Chưa có đánh giá nào.