Compressed Air Filter

Giá gốc là: 230.000 ₫.200.000 ₫Giá hiện tại là: 200.000 ₫.

Cập nhật lần cuối ngày 15/08/2025 lúc 04:32 chiều

Understanding Compressed Air Filters

Compressed air filters are devices used to filter compressed air and remove contaminants such as dust, water vapor, and other impurities present in the compressed air before it is used to operate other compressed air devices in a system.

To effectively filter the compressed air, these devices are installed along sections of pipes through which the compressed air flows. With their special design and arrangement of filter membranes inside, they capture and retain dirt and condensed water.

Why is it necessary to use compressed air filters?

It is normal for compressed air to contain contaminants because it is generated from ambient air and compressed using air compressors.

If these contaminants are not removed, they can cause instability in the system’s operation. Additionally, the presence of dust and accumulated water inside the system can reduce the lifespan of the equipment that utilizes compressed air. Therefore, the use of compressed air filters is highly necessary.

Technical specifications of compressed air filters

- Operating pressure limit: 10 bar, 16 bar, etc.

- Port size: 1/8 inch, 1/4 inch, 3/4 inch, etc.

- Port connection type: Threaded, flanged

- Main construction material: Aluminum, plastic, glass, etc.

- Air flow rate through the filter: 1000m³/minute, 1500m³/minute, 2000m³/minute, etc.

- Operating temperature: From -5℃ to 70℃

- Design: Single filter, dual filter, etc.

- Applicable fluid: Compressed air, nitrogen gas, etc.

- Manufacturers: Airtac – Taiwan, Parker – USA, Festo – Germany, etc.

- Warranty policy: 12 months.

Classification of compressed air filters based on function

Currently, there are many different types of compressed air filters on the market, and naturally, the differences in these types will lead to differences in the features of each product. In the following, we will explore the classification of compressed air filters.

Single Air Compressor Filter

The single cup-shaped air compressor filter is considered the most basic type of filter. The device is provided in the form of a single cup filter that is directly installed on the pipeline. It relies on the arranged filter core inside the product to capture dust and moisture accompanying the compressed air during operation.

With this type of filter, we have two functional options: choosing products designed with pressure regulating valves or choosing products that solely function as air purifiers.

The single filter is used in many compressed air systems and is available in various sizes. For large-sized equipment, the filter cup component is usually cast from a solid metal block and installed immediately after high-capacity air compressors to provide preliminary filtration for the entire factory. For smaller-sized equipment, they are used in conjunction with parts, devices, or behind low-capacity air compressors, entering into the operation of pneumatic devices.

Dual Air Compressor Filter

The dual cup-shaped air compressor filter is designed with two adjacent filter cups. However, this type of device usually does not have corresponding filter cores for each cup. Instead, one cup is responsible for filtration while the other cup is designed to contain lubricating oil. When compressed air with high pressure flows through this component, it carries a small amount of oil into pneumatic devices. This oil serves the purpose of lubricating the interacting mechanisms during operation.

Most of the dual cup air compressor filter devices are equipped with pressure regulating valve components on their bodies. These valves provide the function of adjusting the pressure of the compressed air after it passes through the filter. In the oil-containing cup component, an oil control valve is arranged to regulate the amount of oil supplied to the system, depending on the pneumatic device’s requirements.

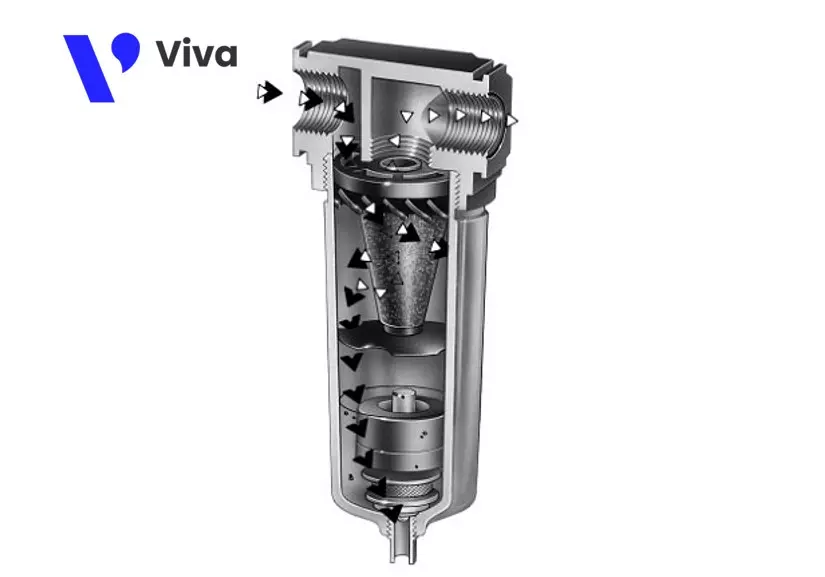

Structure of Air Compressor Filter

As you may know, there are various types of air compressor filters available and used in compressed air systems. These types differ in terms of functionality and structure.

In this article, we will explore the structure of the basic type of air compressor filter.

The air compressor filter is composed of the following components:

- Filter Cup: This component is designed in the shape of a cup, made of transparent materials such as glass or plastic, allowing users to observe the condition of the filter membrane inside and determine when it needs replacement.

- Filter Element: The filter element is installed inside the filter cup and directly captures the contaminants present in the compressed air within the system. The filter element is typically designed in a cylindrical shape and is commonly made of polymer materials.

- Housing: The housing of the air compressor filter is made of aluminum and is responsible for connecting and structurally integrating the various parts and components of the device. Inside the housing, there are ports and pathways that connect to the pipes and guide the airflow to the filter element.

- Drain Valve: The drain valve is positioned at the bottom of the filter cup. It is designed to be open under normal pressure conditions. During operation under the influence of compressed air pressure, the valve automatically closes. When the air compression process is completed, the valve opens, allowing condensed water to flow out. Some devices may use manually operated valves for control based on specific needs.

Operation of Air Compressor Filter

Based on the functionality and structural characteristics of the device, we can see that the operation of an air compressor filter is relatively simple. It involves directing the flow of compressed air through the filter element in a way that maximizes the contact area between the compressed air and the filter element, thus ensuring the highest working efficiency.

The process of purifying compressed air by the device is as follows:

- Firstly, the air compressor filter is installed onto the compressed air pipeline, following the indicated direction on the filter housing. When the compressed air system operates with high pressure, the air flows into the filter through a diffuser component.

The compressed air is divided into multiple streams and circulates inside the filter cup while swirling around the details of the filter element. Throughout the operation, the swirling motion of the compressed air flow maximizes the contact area between the compressed air and the filter element. - Due to the difference in working pressure, the compressed air tends to pass through the filter element. As there are always contaminants present in the compressed air, and these contaminants have much larger sizes than gas molecules, they are trapped by the filter element.

During continuous operation, the moisture in the compressed air condenses and forms water, which then flows down to the bottom of the filter. The bottom of the filter is equipped with drain valves (either automatic or manually operated), allowing the discharge of the condensed water from the filter to the outside.

The above-described process is the basic operation of a basic air compressor filter, which utilizes physical laws to perform the process of purifying compressed air. Additionally, there are other devices that can be used in combination with the filter, such as chemical filters, to enhance the ability to clean compressed air.

Practical Applications of Air Compressor Filter

The main function of an air compressor filter is to clean contaminants and remove condensed water from compressed air. In addition, depending on the product type, this device can be integrated with additional functions, including providing lubricating oil for pneumatic-operated equipment and adjusting the compressed air pressure after passing through the filter. With these functions, the device is used in all compressed air systems that serve various specific applications.

Some examples of the applications of an air compressor filter include:

- Compressed air systems in manufacturing plants: Compressed air systems are widely used in manufacturing plants to perform repetitive tasks or operations, thanks to the combination of various suitable pneumatic devices. The air compressor filter used in the system ensures that the compressed air used to operate the system meets the requirements of cleanliness, stability, and pressure regulation.

- Compressed air systems in repair garages: Both large and small repair garages utilize a wide range of pneumatic tools and equipment. Therefore, a system capable of generating and maintaining an appropriate supply of compressed air is essential in garages. Although their capacity is much smaller compared to industrial-scale systems, they still require the use of air compressor filters to purify the air before using it for pneumatic equipment.

- Applications in various types of machinery and vehicles: Air compressor filters are also commonly used components in certain types of machinery and vehicles, especially on large-scale vehicles such as ships, containers, airplanes, heavy construction machinery, and more.

The above examples highlight the practical applications of air compressor filters. Through this, readers can have a better understanding of the functions provided by this equipment.

Installation and Maintenance Notes for Air Compressor Filters

As you may know, most air compressor filter devices used in compressed air pipelines perform the task of filtering compressed air completely automatically. Therefore, the equipment requires very little adjustment during operation. However, to ensure that the device can function effectively and have a high durability, it is important to pay attention to the installation and maintenance of the product according to the manufacturer’s recommendations.

Installation Notes:

- Select a suitable location for installing the air compressor filter that meets requirements such as easy access and does not obstruct the movement of people or other objects during operation.

- Install the air compressor filter in close proximity to the compressed air source, before the pneumatic devices that use compressed air (such as pneumatic cylinders, pneumatic motors, etc.).

- Install the air compressor filter according to the provided instructions and ensure that the airflow direction indicated on the filter body is followed to ensure efficient operation.

Maintenance Notes:

- Regularly check the condition of the air compressor filter to determine if it is clogged and needs replacement.

- Periodically replace the coarse and fine filters to ensure the effective filtering capability of the filter.

- Periodically inspect the compressed air pipelines to ensure they are not leaking or damaged.

- Regularly check the pressure within the air compressor filter to ensure it is not excessively high or low.

- Perform regular cleaning and maintenance of the air compressor filter to remove impurities, dust, and accumulated oil from the filter surface.

Note that the installation and maintenance of air compressor filters should be carried out by skilled and experienced technicians to ensure the safety and effectiveness of the equipment and the entire compressed air system.

Air Compressor Filter Products at VIVA Company

VIVA Company is one of the leading suppliers of various industrial equipment, including air compressor filters in Vietnam. The products are imported from reputable manufacturers in multiple countries, accompanied by long-term warranty services, allowing customers to have complete peace of mind when choosing VIVA as their product provider.

The air compressor filter products at VIVA Company include:

- Single filters

- Dual filters

- Large industrial filters

- Filters using activated carbon,…

VIVA Company is committed to providing high-quality products that ensure optimal filtration efficiency and long lifespan. In addition, the company offers consulting and technical support services to assist customers in selecting the most suitable products for their needs and addressing any issues related to air compressor filters.

See more air distribution manifold products.

ĐÁNH GIÁ SẢN PHẨM

Đánh giá

Chưa có đánh giá nào.