Electronic water flow meter

Giá gốc là: 7.500.000 ₫.6.600.000 ₫Giá hiện tại là: 6.600.000 ₫.

Cập nhật lần cuối ngày 16/06/2023 lúc 03:16 chiều

Electronic water flow meters are modern flow measurement devices designed to efficiently measure the flow rate of water without disrupting the operation of the entire system. In conventional working systems, these types of flow meters are rarely encountered. However, they are widely used in the industrial sector due to their ability to meet requirements for connectivity, modern features, and challenging working conditions…

Now let’s explore these flow measurement devices in more detail.

Introduction to Electronic Water Flow Meters

Electronic water flow meters are a collection of flow measurement devices that measure the flow rate of water. Their construction incorporates electronic components or electronic sensors instead of being entirely mechanical. These components work together to form dynamic transmission mechanisms and counters.

Depending on the type, electronic water flow meters apply different measurement principles, often based on laws such as Faraday’s law, Theodore von Kármán’s law of vortex motion, the Doppler effect, etc. Each of these laws corresponds to different types of electronic water flow meters, including:

- Turbine-type water flow meters

- Electromagnetic water flow meters

- Ultrasonic water flow meters, etc.

Electronic water flow meters are considered to have the ability to accurately measure flow rates. Additionally, these devices often provide additional features such as temperature and pressure measurement of the working water inside the pipeline, thanks to the use of sensor components.

Technical Specifications of Electronic Water Flow Meters

To choose suitable water flow measurement devices for various applications such as in factories, aquaculture pipelines, irrigation systems, and water supply systems for residential use, it is important to understand the system, estimate parameters like working temperature and pressure, and determine the desired features. Then, these requirements can be compared with the technical specifications of the devices to find the appropriate products.

The technical specifications of electronic water flow meters include:

- Measurement Functions: Flow rate measurement, temperature measurement, pressure measurement

- Meter Body Diameter: DN15 to DN1500

- Types of Meters: Ultrasonic, vortex, electromagnetic, turbine, etc.

- Installation Options: Clamp-on, threaded, flanged, etc.

- Materials: Stainless steel 304, stainless steel 316, carbon steel, etc.

- Working Pressure: 6 bar, 10 bar, 16 bar, etc.

- Working Temperature: -20℃ to 180℃

- Fluid Compatibility: Regular water, wastewater, various industrial liquids, etc.

- Operating Power: 220V/AC, 24V/DC

- Output Signal: 4 ~ 20 mA

- Origin: Germany, China, Japan, etc.

- Warranty Period: 12, 16, or 18 months (depending on the product type).

Classification of Electronic Water Flow Meters

You may not know this, but measuring the flow rate of water in industrial systems involves more than just measuring the flow rate of regular water. Water flowing through different pipeline systems can have various characteristics, including differences in temperature, pressure, viscosity, and even chemical properties.

That’s why various types of water flow meters have been designed.

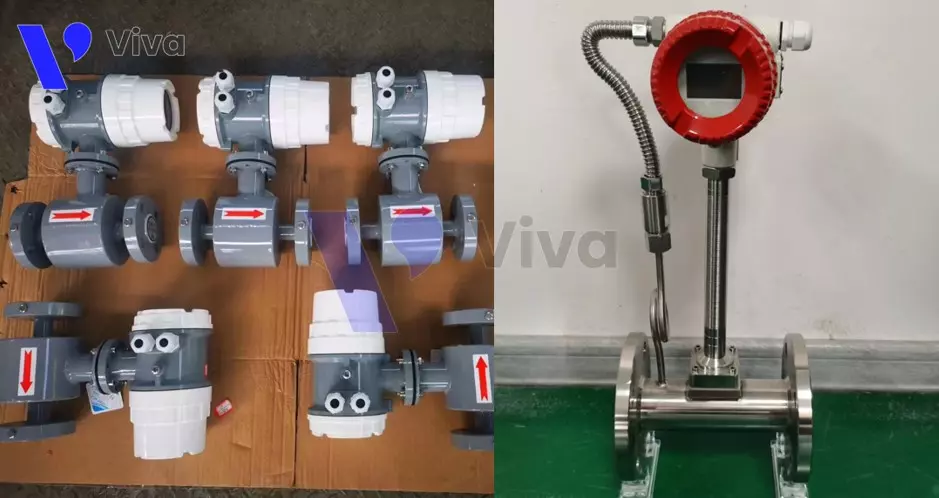

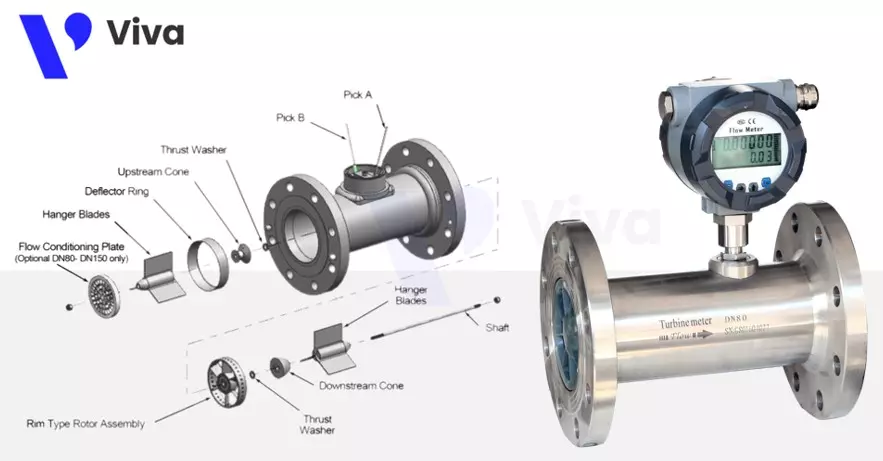

Turbine-Type Electronic Water Flow Meter

The turbine-type electronic water flow meter utilizes a turbine rotor that directly contacts the fluid to sense the velocity of the flow. With the help of a specialized sensor, it can receive and analyze the rotation speed of the turbine rotor, whether it is fast or slow. The built-in processing unit then calculates and provides the corresponding flow rate value based on the flow within the system.

Due to its structure and operating principle, this type of flow meter is suitable for use in clean water pipelines with moderate temperature and pressure. However, when using this device, it’s important to note that the turbine rotor may cause flow disturbance and result in a certain level of pressure loss.

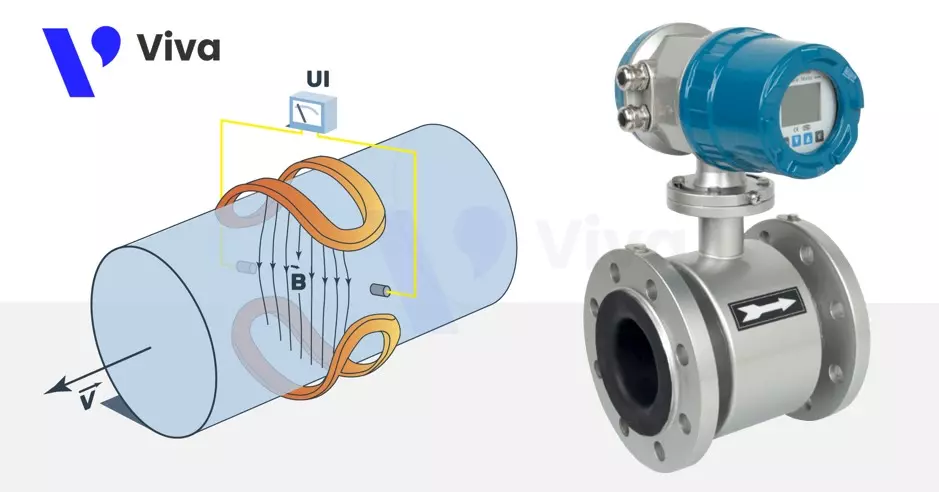

Electromagnetic-Type Electronic Water Flow Meter

Unlike the turbine flow meter that requires direct contact with the fluid to provide feedback on the flow velocity, causing flow disturbance and pressure loss, the electromagnetic-type electronic water flow meter overcomes these limitations. It employs a non-intrusive measurement method based on Faraday’s law, creating an electric potential within the fluid. Electrodes positioned on both sides of the flow meter measure the generated voltage, which is proportional to the flow velocity.

However, this type of flow meter has a limitation: it cannot be used to measure the flow rate of non-conductive or poorly conductive water, such as distilled water (a relatively common fluid used in many industrial systems).

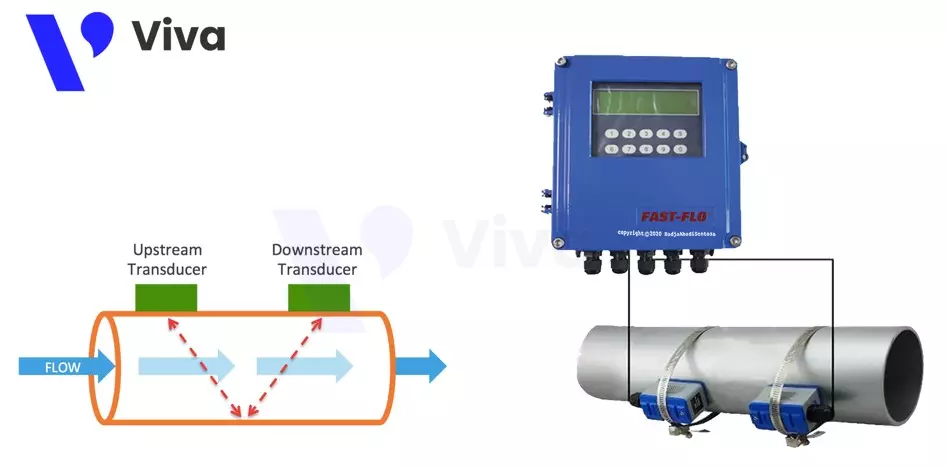

Ultrasonic-Type Electronic Water Flow Meter

The electronic water flow meter utilizing ultrasonic waves has been developed in two main types:

The first type is based on the time difference between the transmission and reception of ultrasonic waves as they pass through the flowing stream. It measures the time delay caused by the flow.

The second type is based on the frequency change of the ultrasonic waves between the transmitting and receiving ends. The frequency change occurs when the ultrasonic waves encounter impurities or air bubbles within the fluid. This type of device has limitations in measuring flows with very slow velocities, where impurities tend to settle at the bottom of the pipeline or where the flow is too slow to generate air bubbles within the fluid.

With its non-intrusive flow measurement capability, the ultrasonic-type electronic water flow meter is suitable for measuring the flow rates of various types of water, including wastewater, water with high impurity content, high-temperature and high-pressure systems, and high-velocity flows.

Vortex-Type Electronic Water Flow Meter

The vortex-type electronic water flow meter, also known as the vortex flow meter, operates by creating vortices within the flowing liquid. These vortices cause periodic pressure fluctuations, and the higher the flow velocity, the greater the occurrence of vortices.

This device is known for its high accuracy in measuring flow rates and can be used for flows with high temperatures and pressures.

However, it is not recommended to use this device for measuring the flow of constantly fluctuating streams. In such cases, the generated vortices are unstable, leading to measurement inaccuracies.

Structure of electronic water flow meters

As mentioned above, there are various types of electronic water flow meters, each with its own methods of measuring the flow rate. This results in differences in their basic structures.

The only common feature in the structure of these devices is that they are all composed of various electronic components combined with some parts formed from mechanical details.

Let’s now explore the basic structure of different types of electronic water flow meters.

Structure of electromagnetic electronic water flow meters

Electronic water flow meters consist of four main components:

- Body: The body of the electromagnetic electronic water flow meter, also known as the conduit, includes a section of pipe connected to the working system through which water flows. The body of this type of meter is mostly coated with ceramic or insulating plastic to minimize electrical signal interference during the measurement process.

- Electromagnetic coil: Consists of two coils of copper wire wound multiple times and placed opposite each other, surrounding the meter’s body.

- Electrodes: The two electrode ends of the flow meter are arranged on the sides of the pipe wall, directly in contact with the liquid. They are used to measure the generated electromotive force in the flowing stream. Most of these electrodes are made of stainless steel 316, while some have higher requirements and are made of special alloys.

- Processor: The processing unit consists of various electronic components combined together. They receive and process information, display the measured values on the screen, and perform other functions.

Structure of ultrasonic electronic water flow meters

Ultrasonic electronic water flow meters are composed of three main components:

- Ultrasonic transducers: Depending on the type, the device can be equipped with one or multiple sets of different transducers.

- Signal transmission cable: This component is responsible for connecting the ultrasonic transducers to the processing and data calculation unit. The cable functions to transmit both the signal and electrical current from the power supply to the transducers to generate ultrasonic waves.

- Calculation and processing unit: This component performs the analysis of the received data combined with the preset parameters to calculate and provide the appropriate flow rate value.

Structure of turbine-type electronic water flow meters

Turbine-type electronic water flow meters are composed of four main components:

- Meter body: This component is designed as a section of metallic pipe, typically made of stainless steel. The two ends of the pipe are designed with flange, thread, or clamp connections. The meter body is connected to the pipeline, allowing the fluid to pass through.

- Turbine assembly: It is a mechanism consisting of multiple parts such as a shaft, turbine blades, and bearings. These parts are made of stainless steel to ensure durability due to continuous movement and direct contact with the fluid. They are assembled and fixed inside the meter body.

- Rotational speed sensor: This component functions to sense the rotational speed of the turbine blades and convert it into an electrical signal before transmitting it to the processing unit.

- Processing unit: It is an electronic circuit formed from various types of electronic components. Its function is to analyze the collected data and provide the appropriate flow rate value.

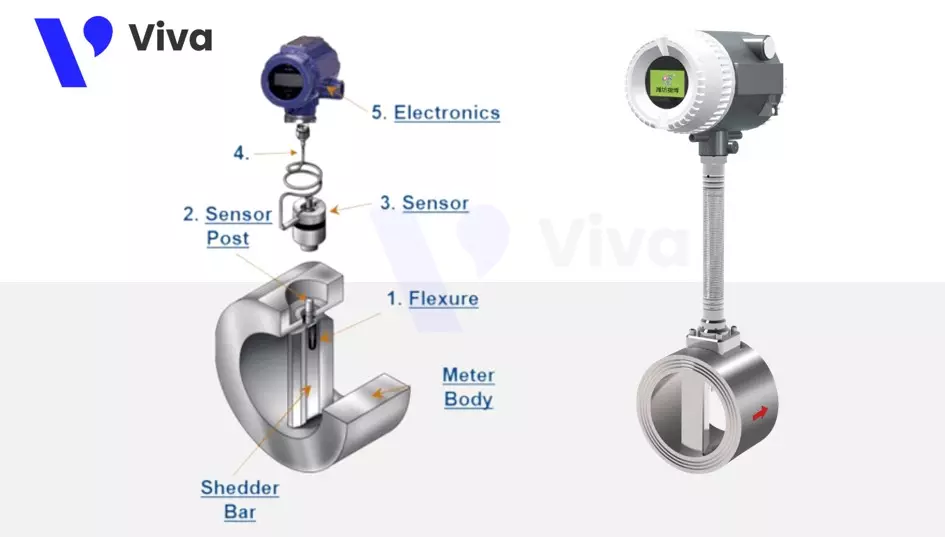

Structure of vortex-type electronic water flow meters

Vortex-type electronic water flow meters are composed of the following main components:

- Meter body: The meter body of the vortex water flow meter is designed similarly to the aforementioned meters. It consists of a metal pipe segment, and it is designed with different installation options such as flange or clamp.

- Vortex bar: It is a specially shaped stainless steel bar fixed inside the pipe at a right angle to the flow direction. When water flows through this component, it creates vortices behind the vortex bar.

- Pressure sensor: The pressure sensor is responsible for detecting changes in the pressure of the flowing fluid, which depend on the frequency of vortex appearance within the meter.

- Processing unit: This component receives the signals of pressure changes from the flow, combines them with algorithms and initial calibration parameters, and analyzes the flow rate value.

Why should you use electronic water flow meters?

Water is an essential resource that is indispensable and utilized in almost all different industries. Furthermore, water plays a crucial role in the existence of all living organisms on Earth. Therefore, the requirement for water conservation and efficient water resource utilization in production processes is a matter of great concern. This is aimed at effectively controlling water resources.

For a long time, devices with the function of measuring flow rates and water usage have been invented. This not only contributes to water resource conservation but also facilitates the measurement and evaluation of the necessary water quantity for production.

Over time, with continuous improvements, modern water flow meters are now available in various types, capable of measuring the flow rates of water in all scenarios.

Among them, the most advanced and feature-rich devices include electronic water flow meters. These devices are a combination of mechanical components, electronic components, and other related parts.

Electronic water flow meters are highly regarded devices that provide accurate flow rate measurements. They are equipped with various sensors, enabling additional measurement features such as pressure and temperature, as well as data logging capabilities.

Comparison of electronic water flow meters with mechanical water flow meters

Water flow meters are provided in two main types: electronic water flow meters and mechanical water flow meters. Each type of meter has its own advantages and disadvantages, making them suitable for different specific cases.

Let’s explore the comparison and evaluation of these two types of water flow meters.

Electronic water flow meters:

- Higher accuracy: Due to the integration of multiple sensors and the use of chips for calculations, electronic water flow meters provide higher accuracy in flow measurement.

- Easier reading of measurements: With LED or LCD displays, the meters show clear and accurate readings, allowing technicians to collect data regardless of low-light conditions.

- Connectivity capabilities: These meters are designed with easy connectivity to a central monitoring computer system, enabling users to easily and effectively control system parameters.

- Wide range of applications: Electronic water flow meters can measure the flow rates of various types of water and work under different conditions and states.

Mechanical water flow meters:

- Cost advantage: Since mechanical water flow meters are entirely made up of mechanical components and have fewer features, their manufacturing process is less expensive compared to electronic components. As a result, mechanical water flow meters are available at lower prices.

- No electricity required: These meters operate solely based on mechanical motion transmission. They utilize the flow force of water through a system of gears and counters to reflect the flow rate.

- Stable operation: The simple construction and operating principle of mechanical water flow meters allow them to adapt well to working conditions. Without electronic circuitry, these products are not affected by dust, humidity, or electronic interference.

Applications of electronic water flow meters

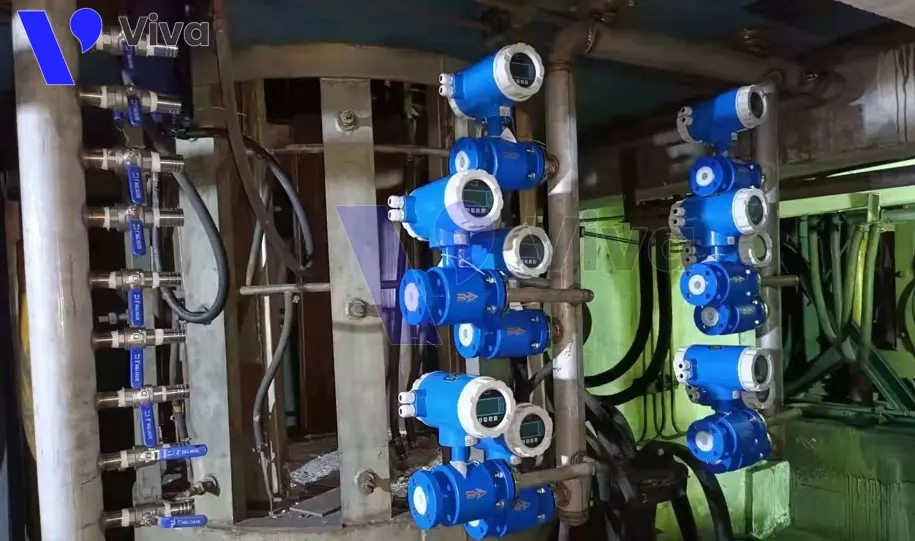

Electronic water flow meters are modern and advanced devices widely used in various practical applications. They are employed for monitoring water flow in wastewater treatment systems, managing water flow in manufacturing plants, measuring water flow in irrigation systems, water supply networks, and cooling systems. These devices enable accurate and efficient monitoring and regulation of water usage, ensuring safety and water resource conservation.

Here are some examples of the applications of electronic water flow meters:

- Monitoring water flow in wastewater treatment systems: The devices are used to monitor water flow in wastewater treatment systems, ensuring that the flow is properly controlled and processed.

- Managing water flow in manufacturing plants: Electronic water flow meters are utilized to manage water flow in manufacturing plants, ensuring proper regulation of the production process.

- Measuring water flow in irrigation systems: They are used to measure water flow in irrigation systems, facilitating the proper management of water usage.

- Measuring water flow in water supply networks: Electronic water flow meters are used to measure water flow in water supply networks, enabling management and regulation of the water supplied to different areas.

- Measuring water flow in cooling systems: They are employed to measure water flow in cooling systems, facilitating regulation and management of water usage in the cooling process.

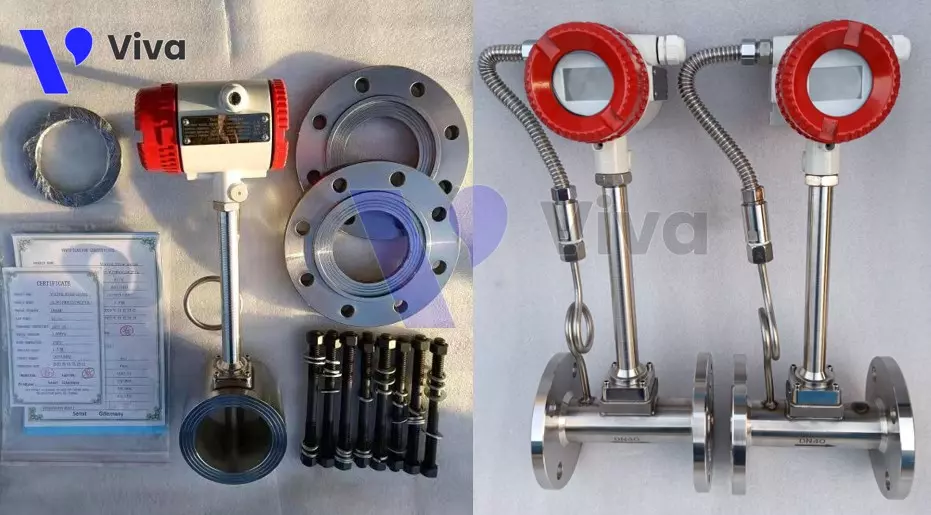

Electronic Water Flow Meters at VIVA Company

VIVA Company provides high-quality electronic water flow meters that meet the usage requirements of customers in various fields. These products are intelligently designed, complying with technical standards and meeting the most stringent customer demands.

The notable features of VIVA’s electronic water flow meters include:

- High accuracy

- Durability and stability

- Easy installation and usage

- Security and energy-saving features

With excellent product quality, outstanding after-sales service, and reasonable prices, VIVA is an excellent choice for businesses and individuals who require electronic water flow meters.

See more products such as differential pressure water flow meters.

Đánh giá

Chưa có đánh giá nào.