Mechanical water flow meter

Giá gốc là: 300.000 ₫.260.000 ₫Giá hiện tại là: 260.000 ₫.

Cập nhật lần cuối ngày 20/06/2023 lúc 05:48 chiều

Water flow meter mechanical type is a widely used flow measuring device in many systems, most commonly seen in water or wastewater systems. The product is supplied in various models and types, and the meter’s connecting ends are designed based on the dimensions of the installation pipes.

Introduction to mechanical water flow meters

Mechanical water flow meters are a type of flow meters. Most of these devices do not provide the measured value in flow rate (m³/h), but instead they typically provide the measured value in water volume (m³). Therefore, to obtain the flow rate value, it is necessary to calculate it using the formula Q = V/ t.

Where:

- Q – flow rate (m³/h)

- V – volume (amount of fluid passing through the meter) (m³)

- t – measurement time (hours).

They operate entirely based on mechanical mechanisms, including:

- Components that come into contact and interact with the flow velocity.

- Driven gear mechanism

- Display mechanism.

The advantages of this type of measuring device are that they can operate based on the force of the flow without the need for any additional power supply. Additionally, being constructed entirely from mechanical parts enhances the durability of the device significantly, particularly reducing costs for the product.

However, mechanical water flow meters are often limited by a wider range of fluids, and their measurement accuracy is lower compared to electronic flow meters. Since the device is entirely composed of mechanical components, it lacks the capability to link and transmit measurement signals to a central computer system.

Technical Specifications of Mechanical Water Flow Meters

As mentioned at the beginning of the article, mechanical water flow meters are supplied in various types as they are imported from multiple manufacturers.

Therefore, the detailed technical specifications of each product may vary. To provide customers with an overview of the technical specifications of the products, we, as a supplier of different types of flow meters, have compiled the following specifications:

- Connection Size: DN8 to DN500

- Device Connection Types: Screwed, Flanged, or Clamp

- Flow Rate Range: 25 m³/h, 50 m³/h, 100 m³/h, and more

- Operating Temperature Range: from 5℃ to 90℃

- Material Options for Meter Body: Epoxy-coated brass, plastic, steel, etc.

- Working Pressure Limitations: 10 Bar, 16 Bar

- Installation Options: Flanged installation, Screwed installation

- Product Origin: Vietnam, Taiwan, China

- Warranty Period: 12 to 18 months (depending on the product)

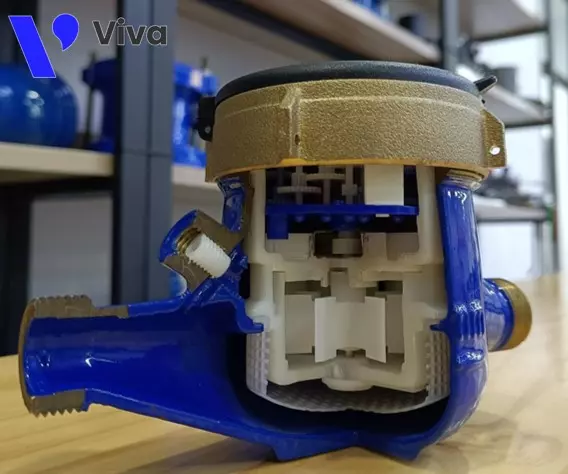

Basic Structure of Mechanical Water Flow Meters

Mechanical water flow meters are entirely composed of mechanical components, which are interconnected to form mechanisms that transmit and convert motion to display the measurement on the meter’s face.

Meter Body

The body of the mechanical water flow meter is typically cast from materials such as ABS plastic, brass, or stainless steel. This allows the device to be used for measuring the water volume of different types of water (clean water, chemicals, non-settling wastewater, etc.). The body serves two main purposes: connecting the meter to the working system through pre-designed connecting ends, usually in the form of screw or flange connections, and linking the various components and parts of the device together.

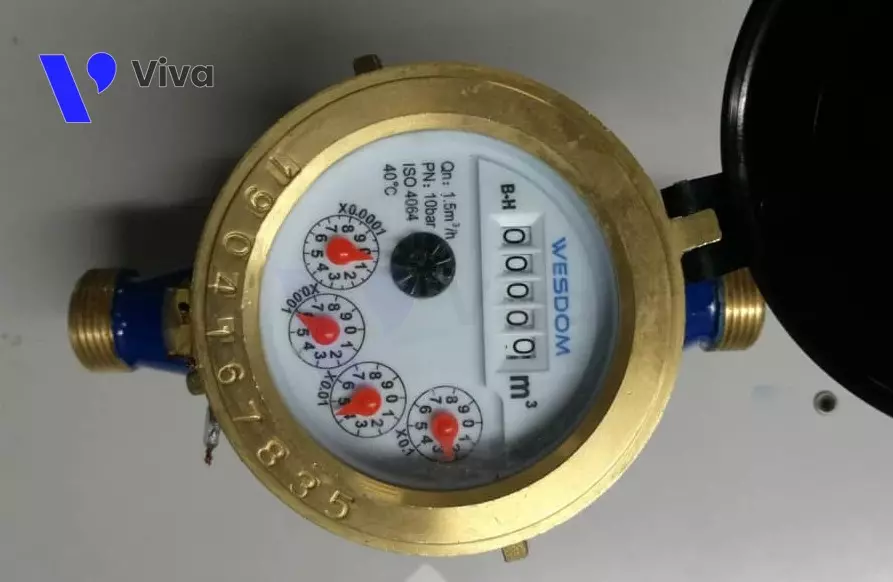

Meter Face

The display face of the water meter serves the function of displaying the measured value through printed numbers and other pointer mechanisms. It is externally protected by a transparent glass, and additionally, a plastic or rubber cover is used to further protect the meter face.

Gear Transmission and Rotation Counting Mechanism

The gear transmission is responsible for transmitting and converting motion from the flow velocity sensing component to the display of the measured value. It consists of a system of intermeshing gear components, often made of plastic materials.

Flow Velocity Sensing Component

This component directly contacts the working fluid and, with its specially designed shape, rotates when in contact with the flow of the fluid. Typically, this component is designed in the form of turbine blades, impeller blades, or discs, depending on the manufacturing unit, with plastic being a common material used.

The rotation speed of this component is proportional to the flow velocity.

Operating Principle of Mechanical Water Flow Meter

A mechanical water flow meter operates based on mechanical principles to measure the flow of liquid or gas through a pipeline. Its operating principle is implemented through an internal mechanism, including a counter, a measuring component, and a driving mechanism.

In some models of mechanical water flow meters, the internal mechanism consists of a rotatable component attached to the main axis of the meter. When the liquid or gas flows through the pipeline, it causes the rotation of this component at a speed corresponding to the flow rate of the fluid. With each rotation of this component, a certain number of pulses are generated and counted by the counter. The quantity of these pulses indicates the amount of liquid or gas that has passed through the meter.

Different types of flow meters may have different operating mechanisms, but the general principle remains the use of an internal mechanism to measure the flow rate of the fluid.

The cycle of the device occurs as follows:

- As water flows through the meter body under the influence of flow force and water pressure, it passes through the internal mechanism (usually a turbine). The rotation speed of this component is proportional to the flow velocity.

- The rotational motion of the turbine is then transmitted to the rotation counter through specific linkages between the turbine and the counter.

- At the mechanical counter, the rotational motion is converted into the rotation of number wheels marked from 0 to 9 in sequential order.

Diverse Range of Mechanical Water Flow Meters at VIVA

We directly import mechanical water flow meters from manufacturing factories, offering a wide variety of products that meet the requirements set by different systems.

Diverse Installation Types

Mechanical water flow meters are commonly installed on water pipelines. Therefore, the installation type must be compatible with the pipe’s mounting method, ensuring pressure resistance and ease of installation.

The commonly used installation types for mechanical water flow meters are:

- Flanged mechanical water flow meter: The meter is designed with flanges at both ends, and this flange installation type is typically applied to devices of medium and larger sizes. It provides quick and easy assembly and disassembly, making it suitable for use in factories and manufacturing facilities.

- Threaded mechanical water flow meter: Compared to the flanged installation type, the threaded mechanical water flow meter is more commonly used for measuring water flow in household water supply pipes. The threaded installation type is suitable for devices with smaller diameters, providing quick and convenient installation, along with the use of additional installation accessories.

Diverse Materials for Manufacturing

Due to the working conditions of various systems, it is necessary to use different materials for manufacturing mechanical water flow meters in order to take advantage of the favorable characteristics of each material.

Currently, mechanical water flow meters are manufactured using the following materials:

- Brass: Brass is an alloy of copper and zinc. It has various applications in different fields, including industrial use for manufacturing various types of equipment and accessories. Brass is chosen for its good corrosion resistance, hardness, heat resistance, and flexibility. In the case of mechanical water flow meters, brass is used to manufacture the meter body and some small components.

- Plastic: Mechanical water flow meters made of plastic have many outstanding advantages such as good impact resistance, chemical corrosion resistance, high durability, and low cost. However, these products have limitations in terms of low temperature and pressure resistance. Therefore, they are suitable for installation in regular pipe systems. It is also recommended not to use them outdoors to enhance product durability.

- Steel or Stainless Steel: Steel and stainless steel are both iron alloys, but stainless steel has a higher cost and better resistance to chemicals. Mechanical water flow meters made from these materials can withstand high working temperatures and pressures.

Advantages and Disadvantages of Mechanical Water Flow Meters

For general machinery and specifically flow measuring devices, each has its own distinct advantages and certain limitations. This is why researchers have developed various types of mechanical water flow meters.

No meter is perfect; it simply suits certain working conditions. To make an appropriate choice, it is necessary to understand the advantages and limitations of the product.

Advantages

Stable operation: Due to its mechanical construction and the inclusion of a strainer to prevent foreign objects from entering the meter, the mechanical water flow meter provides more stable measurements. It is not affected by electrical interference, unstable electric fields, and similar factors.

No energy consumption: The device operates solely based on the flow force of the water acting on the impeller, without requiring any additional energy source to sustain its operation. This allows the meter to be used in areas with limited access to power sources.

Easy and simple to use: The device operates purely through mechanical components, requiring only installation and connection to the system to automatically function. No calibration steps are necessary.

Disadvantages

Low accuracy: Compared to other types of flow meters such as electromagnetic or vortex flow meters, mechanical devices have lower accuracy.

Due to direct contact measurement with the fluid, the accuracy of the measurement is influenced by the working fluid inside the system.

Limited functionality: Unlike electronic flow meters that integrate more features or can be used to measure various types of liquids, mechanical flow meters are designed only to measure the flow rate of water passing through the device.

Practical Applications of Mechanical Water Flow Meters

Mechanical water flow meters are used to test and monitor the flow rate of water through pipelines, with a variety of different types and sizes. These devices are used in various pipeline projects across different fields.

Some examples of practical applications of mechanical water flow meters:

- Most commonly, they are used to measure the consumption of domestic water in households, buildings, offices, schools, etc.

- Used to assist in controlling the water usage for livestock, irrigation purposes in farms.

- These meters are used to measure the supply of water for swimming pools, supply for storage tanks and reservoirs serving the production processes of factories.

See more products: Emflow Water Flow Meter.

Đánh giá

Chưa có đánh giá nào.