Electric control gate valve

Giá gốc là: 6.990.000 ₫.6.500.000 ₫Giá hiện tại là: 6.500.000 ₫.

Cập nhật lần cuối ngày 14/06/2023 lúc 03:48 chiều

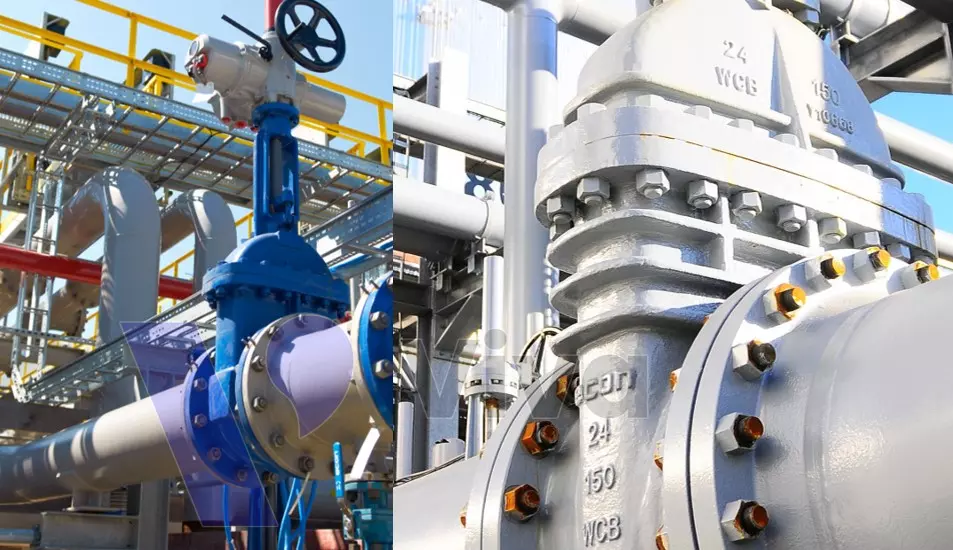

Introduction to Electric Control Gate Valve

Electric control gate valve is a device that plays a very important role in many different systems, unlike other electric control valves such as butterfly valves or ball valves. Electric control gate valves are relatively large in size, so they are only used in certain specific systems.

If you are looking for information related to this product such as structure, operating principles, product classifications, etc., this article will answer all your questions.

What is an Electric Control Gate Valve?

An electric control gate valve is an upgraded version of the classic manually operated gate valve.

Instead of using a handwheel to adjust the working state, electric control gate valves are equipped with an electric actuator to perform this task.

Similar to other control valves, the electric actuator of the valve offers customers options for different electric currents and working voltage levels. Specifically, regarding the electric current, customers can choose between direct current or alternating current frequency (50/60Hz), and the working voltage can be 380V, 220V, 110V, 48V, 24V, etc. However, the structure of the actuator for gate valves is completely different from that of ball valves and butterfly valves.

The electric control gate valve is responsible for regulating the flow of fluid within the pipeline system by lifting and lowering the valve disc. With the electric actuator, controlling the valve disc is much easier and faster.

Our products are usually large in size, and the two valve ports are quite far apart. Due to these characteristics, electric control gate valves are usually designed in a flange-mounted style.

Technical Specifications

For each electric control valve, there are various types of valves available to optimize performance in different working conditions.

The technical specifications provided below for the electric control gate valve are general specifications for common valve types. There may be specific devices designed outside these specifications. To better understand the specifications of each specific device, you can contact us directly for consultation.

- Product line: Electric control ball valve

- Valve body materials: Cast iron, carbon steel, stainless steel, etc.

- Valve size: DN50 to DN1000

- Operating temperature: -29.9°C to 180°C

- Operating pressure: 16bar, 25bar, 40bar, etc.

- Operating mode: On/off or linear

- Operating voltage: 380V, 220V, 24V, etc.

- Valve installation type: Flanged

- Flange face standard: ANSI, BS, DIN, etc.

- Water resistance standard: IP65, IP67

- Brand: Covna, Rotork, Nortech

- Origin: China, Taiwan, Europe, etc.

- Product warranty period: 12 months

Structure of electric control gate valve

The electric control gate valve has a complex structure to form a complete device. The valve consists of many different components and parts. Based on the basic structure and function, the electric control gate valve can be divided into two main parts: the electric actuator and the gate valve body.

Electric actuator

The electric actuator of the electric control gate valve has the task of receiving and transforming electrical energy into suitable rotary motion to control the process of raising and lowering the gate valve.

Unlike the electric actuators used in butterfly valves and ball valves, which produce 90-degree rotary motion, the electric actuator used in gate valves is a multi-turn electric actuator.

The multi-turn electric actuator of the electric control gate valve is usually large in size and can be used not only for gate valves but also for ball valves.

The electric actuator used for gate valves has the following special functions:

The device is equipped with a built-in manual operation mechanism. To activate the manual operation mechanism, the user needs to close the clutch lever and then turn the steering wheel on the control unit according to the predetermined directions. When not using the manual operation mode, the clutch will be disengaged to allow the valve to operate normally.

In addition to directly adjusting the device, the electric drive system of the gate valves can also be controlled by Bluetooth or infrared waves.

The protective casing is designed to meet the waterproof standards IP65, IP67, …

It performs well under continuous high-intensity working conditions, allowing for 60 openings and closings within 1 hour.

Valve Body Components

The body of the electric control gate valve is composed of multiple different parts and components, which are the parts directly in contact with the fluid. The valve body needs to be designed to meet the requirements of pressure resistance, chemical corrosion resistance, tightness, and ease of installation on the pipeline system.

The valve body is made up of various parts and components, of which the main ones are:

Gate Valve Body: The gate valve body consists of two main parts, the upper body (bonnet) and the lower body, both of which are cast from steel, cast iron, or stainless steel. After the casting process, they are subjected to machining and trimming to remove any excess material and to achieve the necessary precision for the surfaces that will be connected to other parts.

The valve body’s task is to connect the structural components together to form a complete device and protect the internal components. The flanged ends of the valve body allow for easy installation onto the pipeline.

Valve Disc: There are two common types of valve discs used in gate valves, namely the two-piece disc and the one-piece disc. Typically, they are cast from stainless steel, but with some devices designed to work with low-pressure systems, the valve disc can be made of certain types of plastics.

The disc is connected to the valve stem, allowing the user to control the lifting or lowering of the disc to open, close, or regulate the flow.

Valve Stem: This component is made of stainless steel and undergoes cutting and threading processes. One end of the stem is connected to the valve disc, while the other end is connected to the electric drive system.

Valve Seat Rings: They are made of alloy and can be welded onto the valve body to improve the sealing efficiency of the valve.

In addition to the main components mentioned above, the gate valve body is also composed of various auxiliary parts that assist in fixing and sealing the valve body, such as sealing gaskets, bolts, embedded screws, and retaining rings.

Principle of operation of electric control gate

Basically, the operation principle of an electric control gate is similar to that of a manually operated gate, which involves opening, closing, and regulating the gate based on the lifting and lowering of the gate leaf.

However, instead of operating the gate through a steering wheel like in the traditional manual type, the power to operate the gate is provided through an electric drive system. The working cycle of the device is as follows:

First, power is supplied to the electric drive system, which, combined with control signals from the electronic circuit board, processes and transforms the current to supply the electric motor.

The electric motor converts electrical energy into mechanical energy, generating rotational motion and transmitting it to the gear drive unit. Here, the rotational motion is transformed to reduce the rotational speed and increase the torque.

The motion is then transmitted to the gate shaft and transformed into upward or downward motion of the gate shaft (depending on the direction of rotation) through the lifting mechanism of the screw shaft.

Finally, with the connection between the gate leaf and the gate shaft, the working state of the electric control gate is changed.

Advantages and disadvantages of electric control gate

Although they have the same functions of opening, closing, and regulating the flow of fluids, various types of control valves are produced due to their individual advantages and disadvantages. They are designed to be suitable and provide optimal performance for different systems.

Smart consumers will understand the advantages and disadvantages of the devices, understand the requirements of their systems, and know what type of equipment they need to apply in the most reasonable way. Below is my sharing of the advantages and disadvantages of the electric control gate device, hoping to assist customers in the process of considering product selection.

Advantages

With a special structure that allows electrically controlled gate valves, they can work in high-pressure systems (PN16 and above). They come in various sizes ranging from DN50 to DN1000, meeting the needs of almost all pipeline systems in Vietnam.

The valve body is made from diverse materials, striking a balance between technical requirements and product costs.

The simple operating principle results in high efficiency, with minimal pressure drop of the fluid after passing through the valve (which is particularly significant for large pipeline systems with high viscosity fluids).

There are multiple options for the control current and working voltage levels.

The equipment has high durability with a drive mechanism designed to meet IP65 and IP67 standards. The working temperature range for the valve body is from -30 to 180 degrees Celsius, and for the electric drive mechanism is from -20 to 60 degrees Celsius, allowing the equipment to operate in various environmental conditions.

The electric drive mechanism is multifunctional, allowing users to control the device remotely, in line with the general trend towards automation requirements.

Disadvantages

The main disadvantage of this equipment is its cost, which can vary depending on the type of valve. In general, electrically controlled gate valves are quite expensive.

The valves have large dimensions, especially when compared to electrically controlled butterfly valves of the same diameter. The large size leads to significant weight, making installation difficult. In systems where the pipelines experience vibrations during operation, the weight of the valve can contribute to increased oscillations.

Applications of electrically controlled gate valves

Despite having a few drawbacks, the outstanding features of electrically controlled gate valves make them highly suitable for use in various systems. However, in Vietnam, this equipment is not as commonly used as electrically controlled butterfly valves or electrically controlled ball valves. Nevertheless, in many countries around the world, this type of valve is widely used and applied in:

- Commonly used on pipelines in oil refineries.

- Applied in hydroelectric, thermal power plants, and cooling systems of nuclear power plants.

- Used in oil and gas pipelines crossing multiple countries and regions.

- Applied in water treatment plants and systems serving irrigation purposes.

And many other applications.

VIVA – Reliable Address for Electrical Gate Control Valves

To meet the domestic demand for electrical gate control valves, VIVA Technical and Industrial Equipment Joint Stock Company has imported these devices from reputable units.

Our products not only meet the technical requirements but also cater to various customer segments.

If you are seeking high-quality products that fully comply with European standards, we have devices directly imported from the United States, Germany, Spain, and more.

For budget-friendly options without compromising quality, you can consider devices imported from India, China, Taiwan, Japan, etc. These products have lower prices but still maintain good quality. Alternatively, you can choose some products with fewer features.

As a testament to the quality of the products distributed by VIVA, we ensure a warranty period of up to 12 months from the delivery date.

As a specialized supplier of valve industry equipment, we offer a wide range of electrical control valves, including:

- Electrical butterfly valve from Taiwan

- Electrical butterfly valve

- Electrical ball valve,…

For more detailed information about our products or purchasing policies, please contact us directly for prompt assistance.

See more: Electrical ball valve

Đánh giá

Chưa có đánh giá nào.