The standard specifications for JIS, DIN, BS, ANSI, EN 1092-1, and ISO flanges

The flange standards are regulations concerning the size and pressure used for flanges in pipeline applications. These standards include ANSI, BS, DIN, JIS, and ISO and are established to ensure compatibility and safety when connecting pipes and pipelines. Each flange standard has specific requirements for dimensions and corresponding pressure based on different pipe types and working pressures.

Specifications of JIS, DIN, BS, ANSI, EN 1092-1, and ISO flange standards

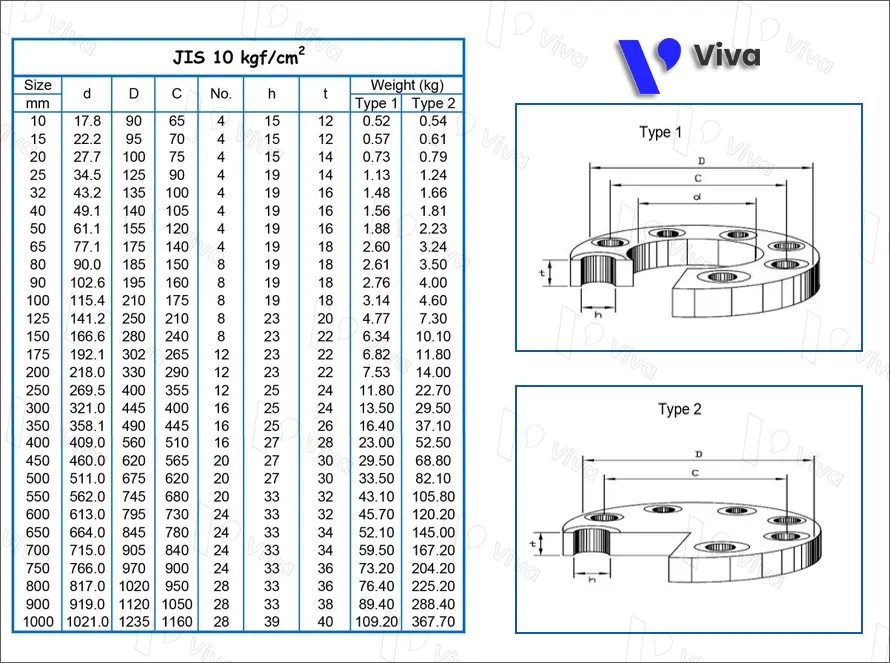

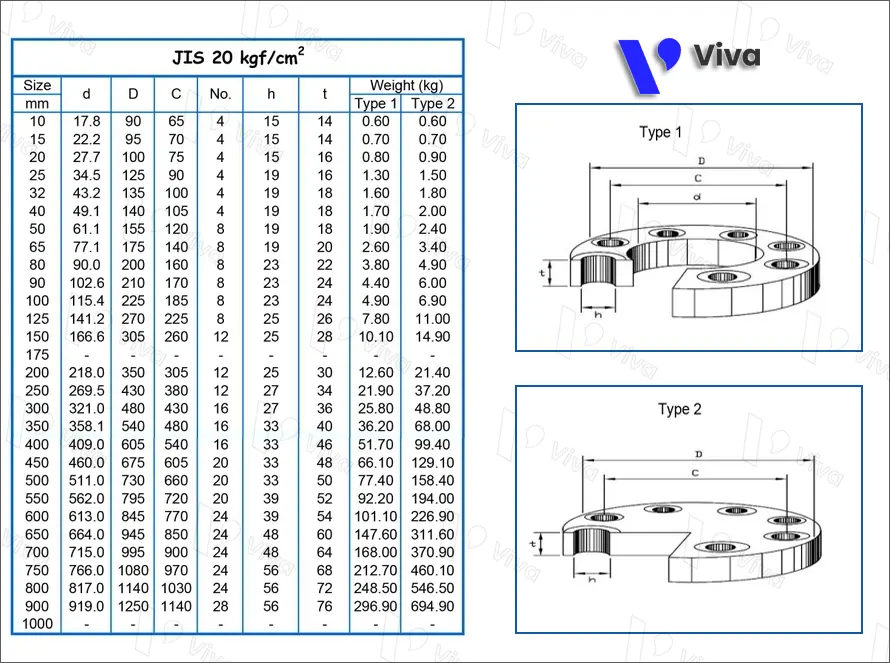

Table of JIS flange standards 5K, 10K, 16K, 20K

- JIS 5K:

- JIS 10K:

- JIS 16K:

- JIS 20K:

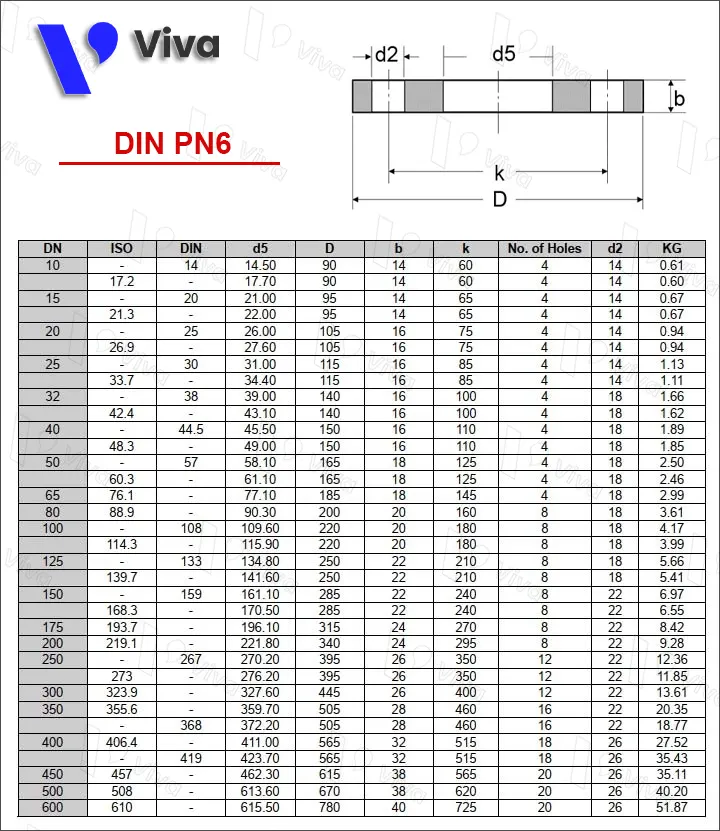

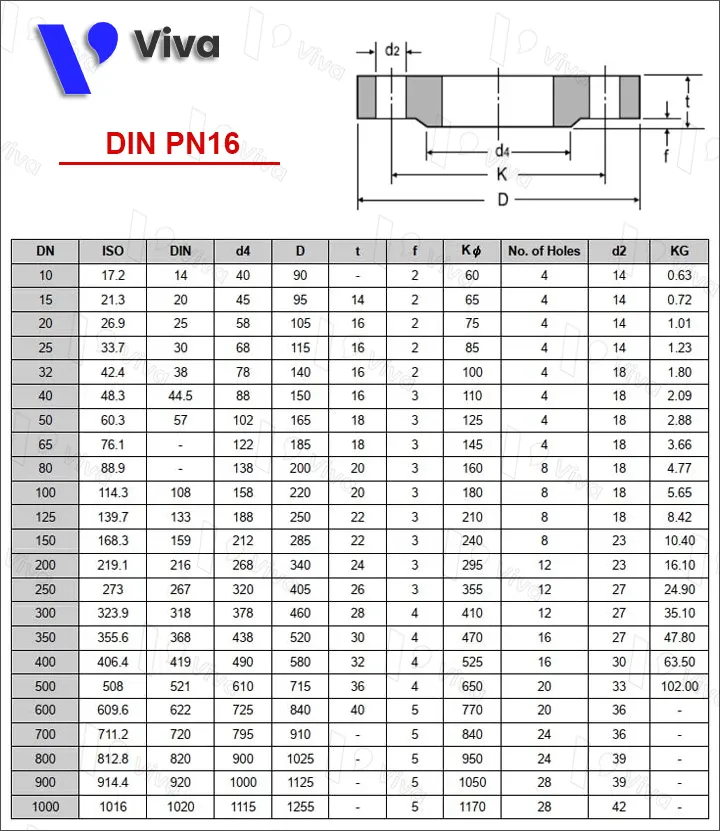

Table of DIN flange standards PN6, PN10, PN16, PN25, PN40

- DIN PN6:

- DIN PN10:

- DIN PN16:

- DIN PN25:

- DIN PN40:

Table of BS flange standards PN6, PN10, PN16, PN25, PN40

- BS 4504 PN6:

- BS 4504 PN10:

- BS 4504 PN16:

- BS 4504 PN25:

- BS 4504 PN40:

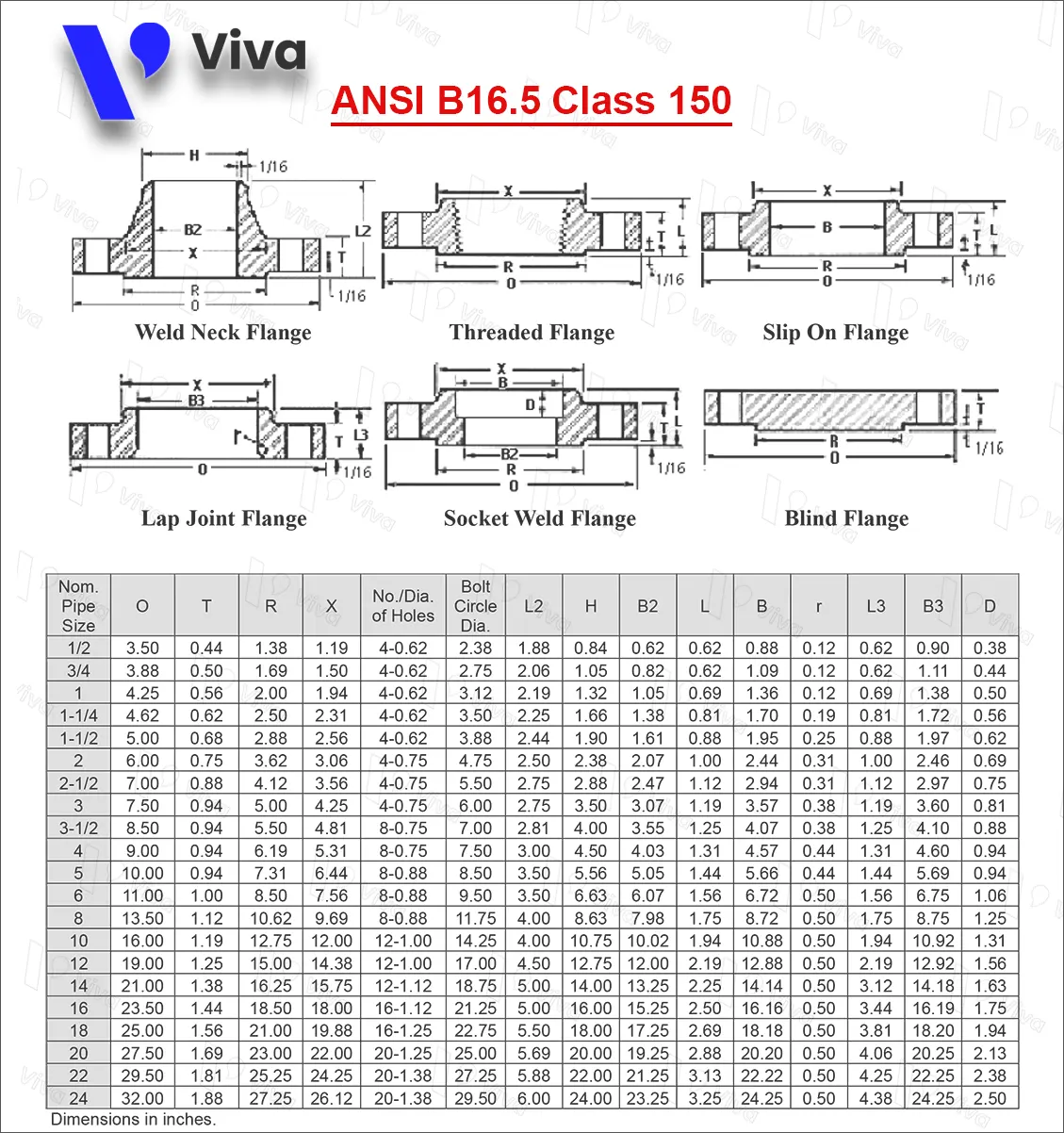

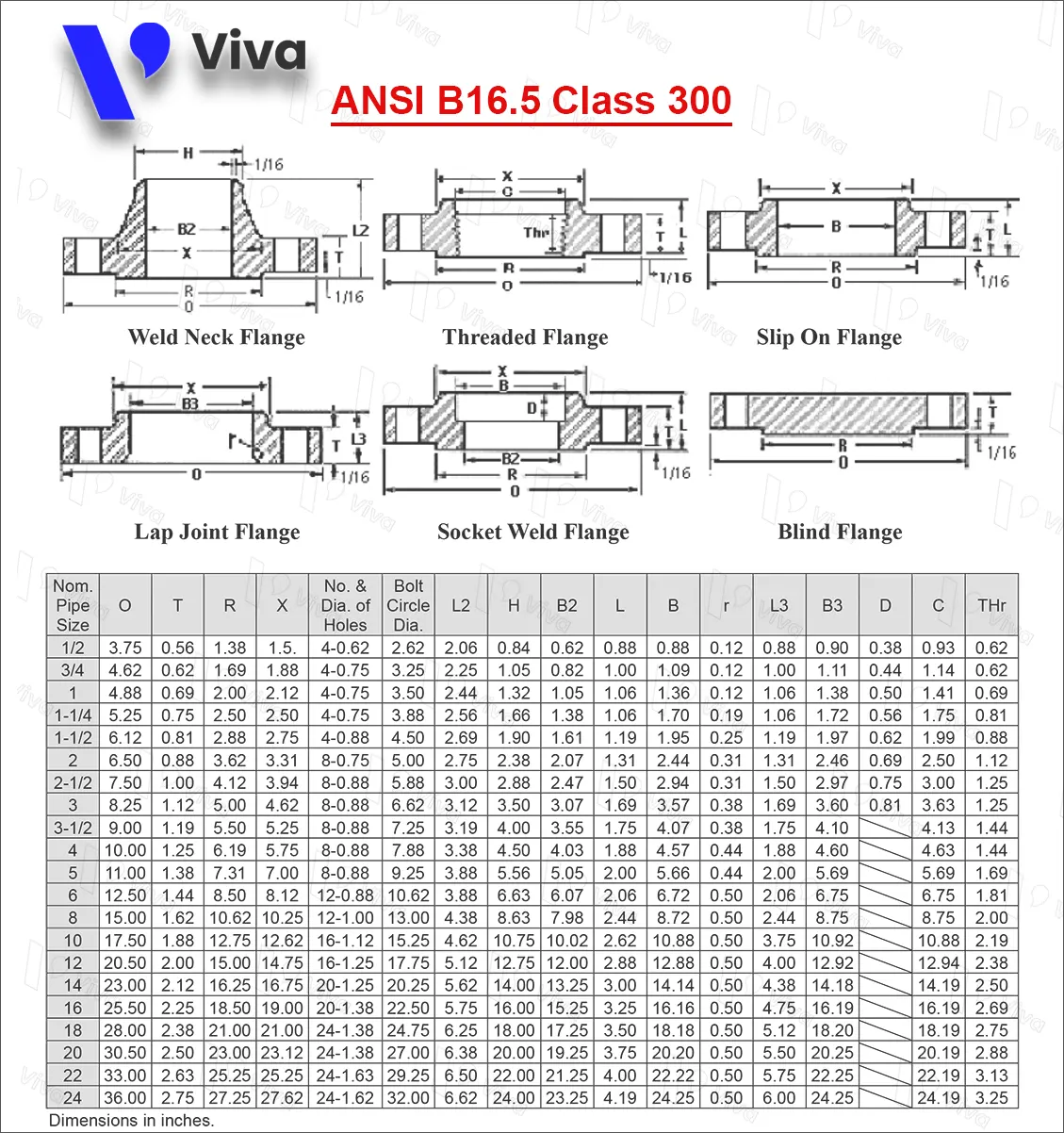

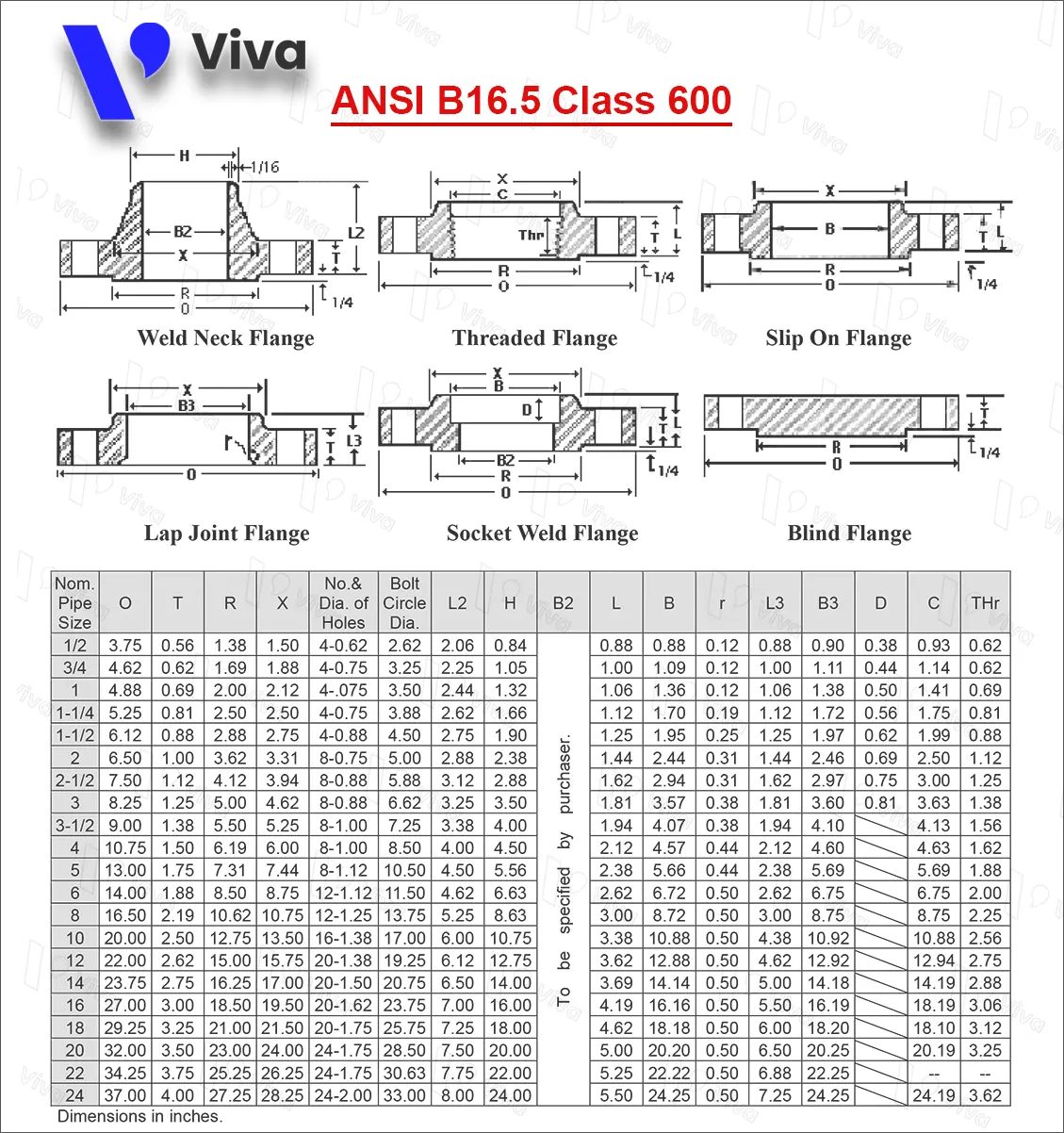

Flange Face Standards Chart ANSI B16.5 Class 150, 300, 600

- ANSI B16.5 Class 150:

- ANSI B16.5 Class 300:

- ANSI B16.5 Class 400:

- ANSI B16.5 Class 600:

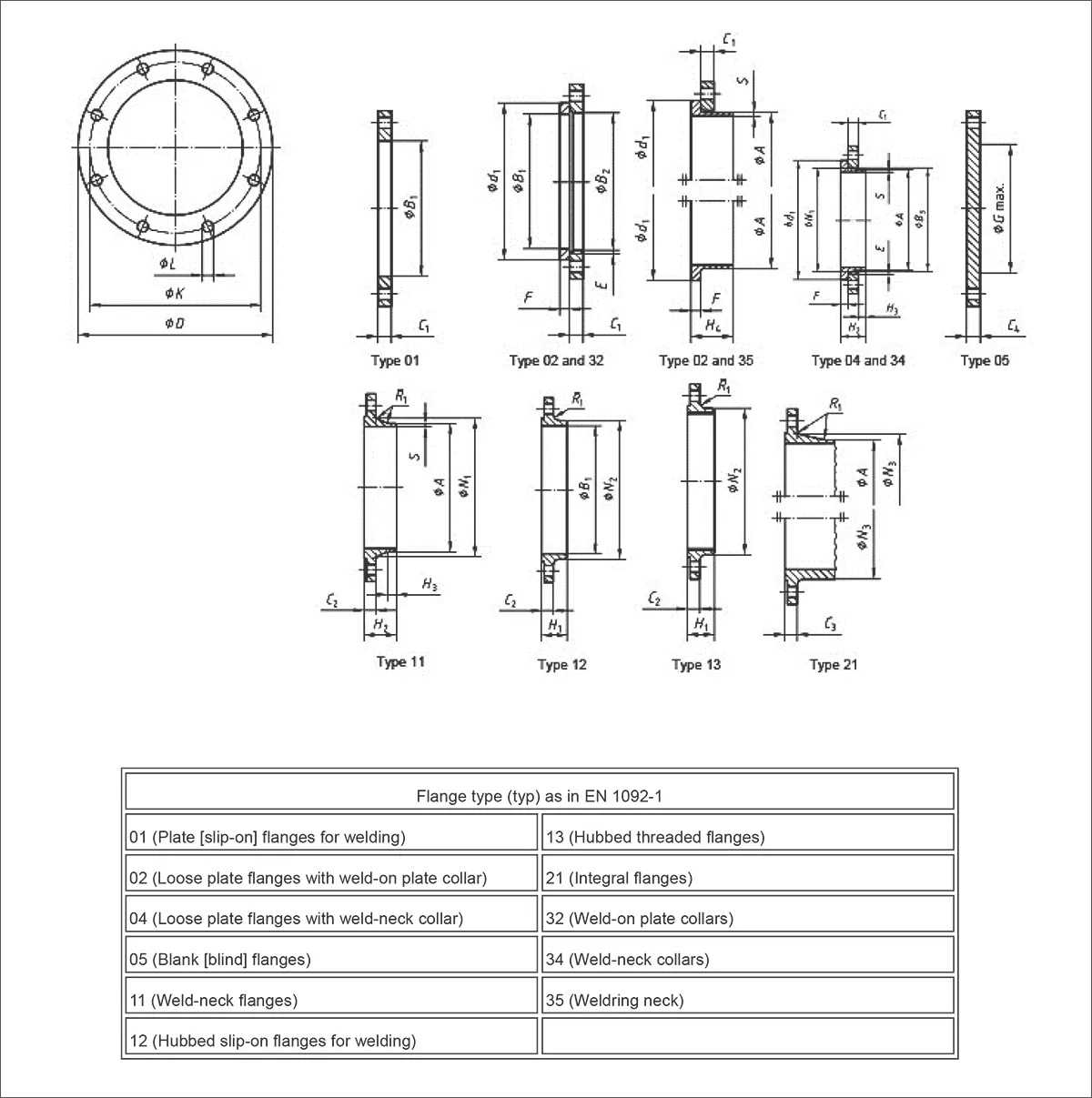

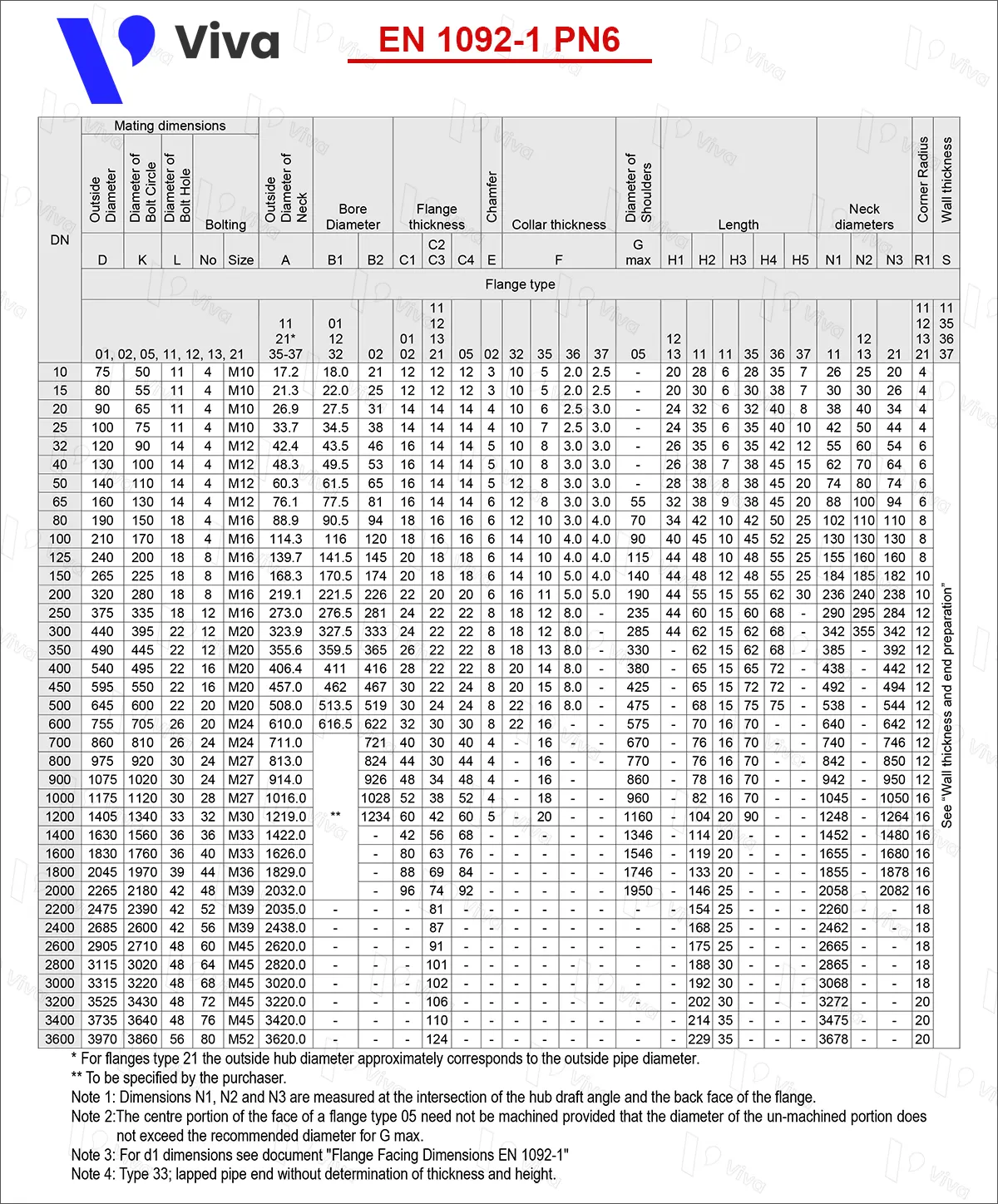

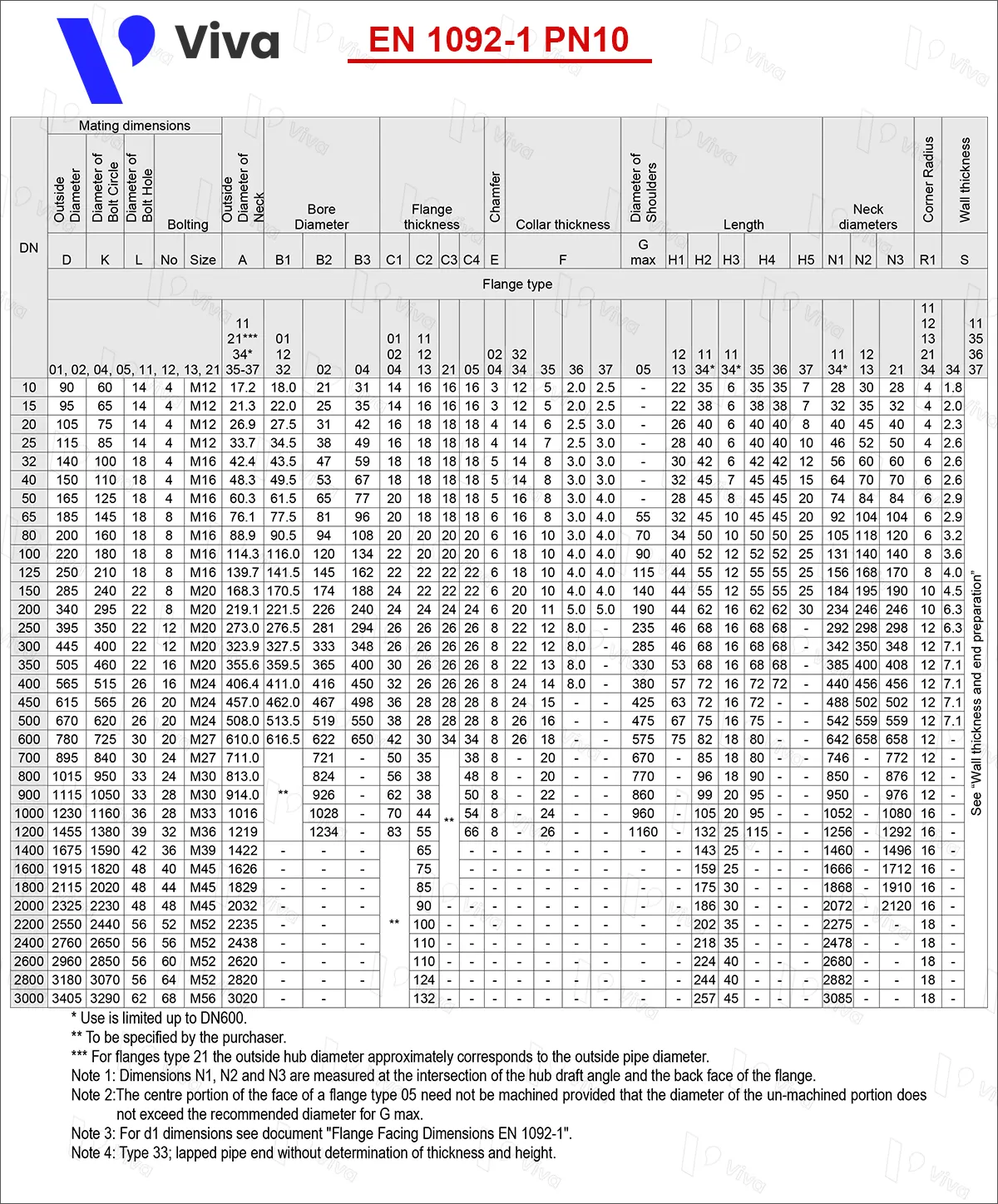

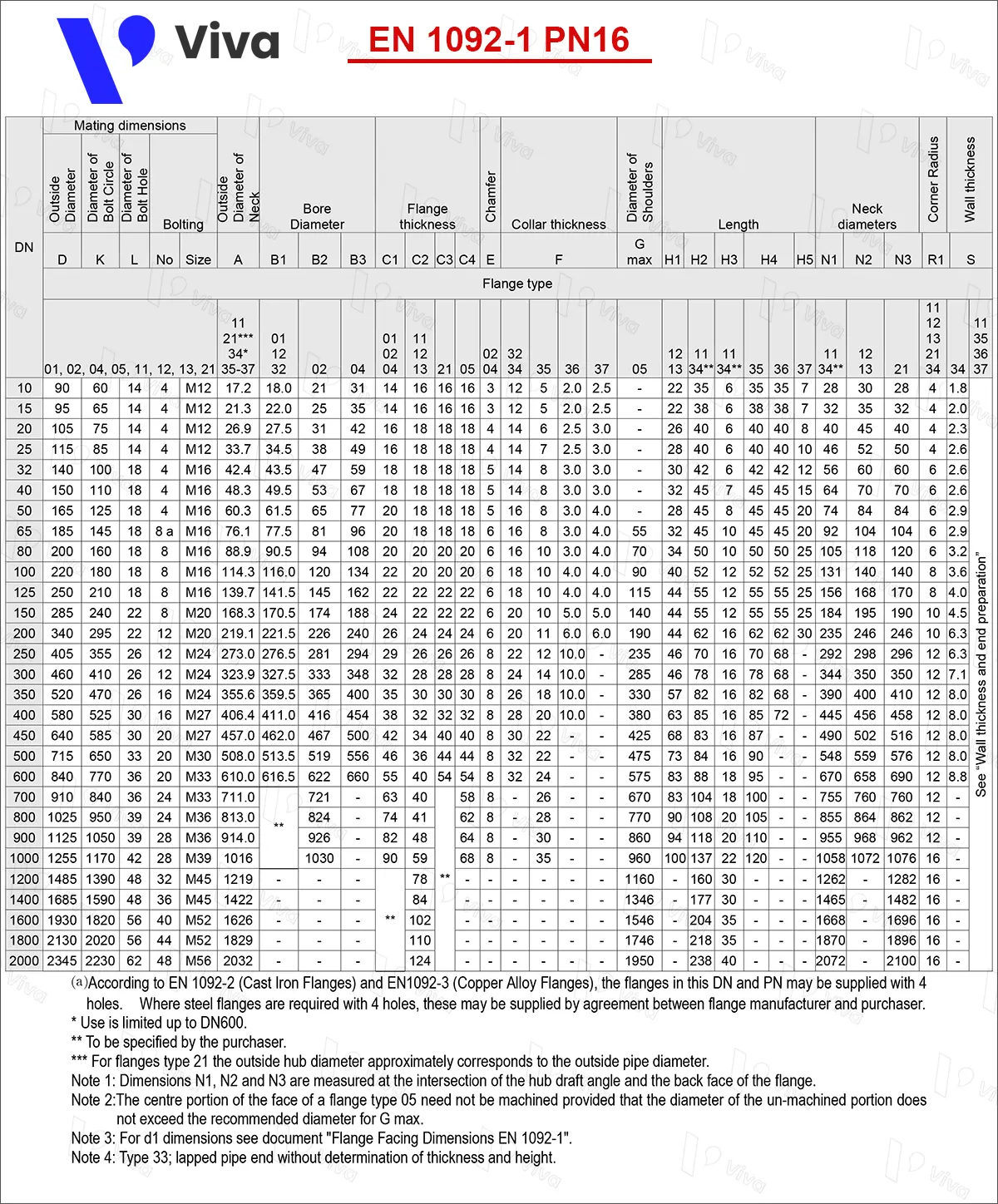

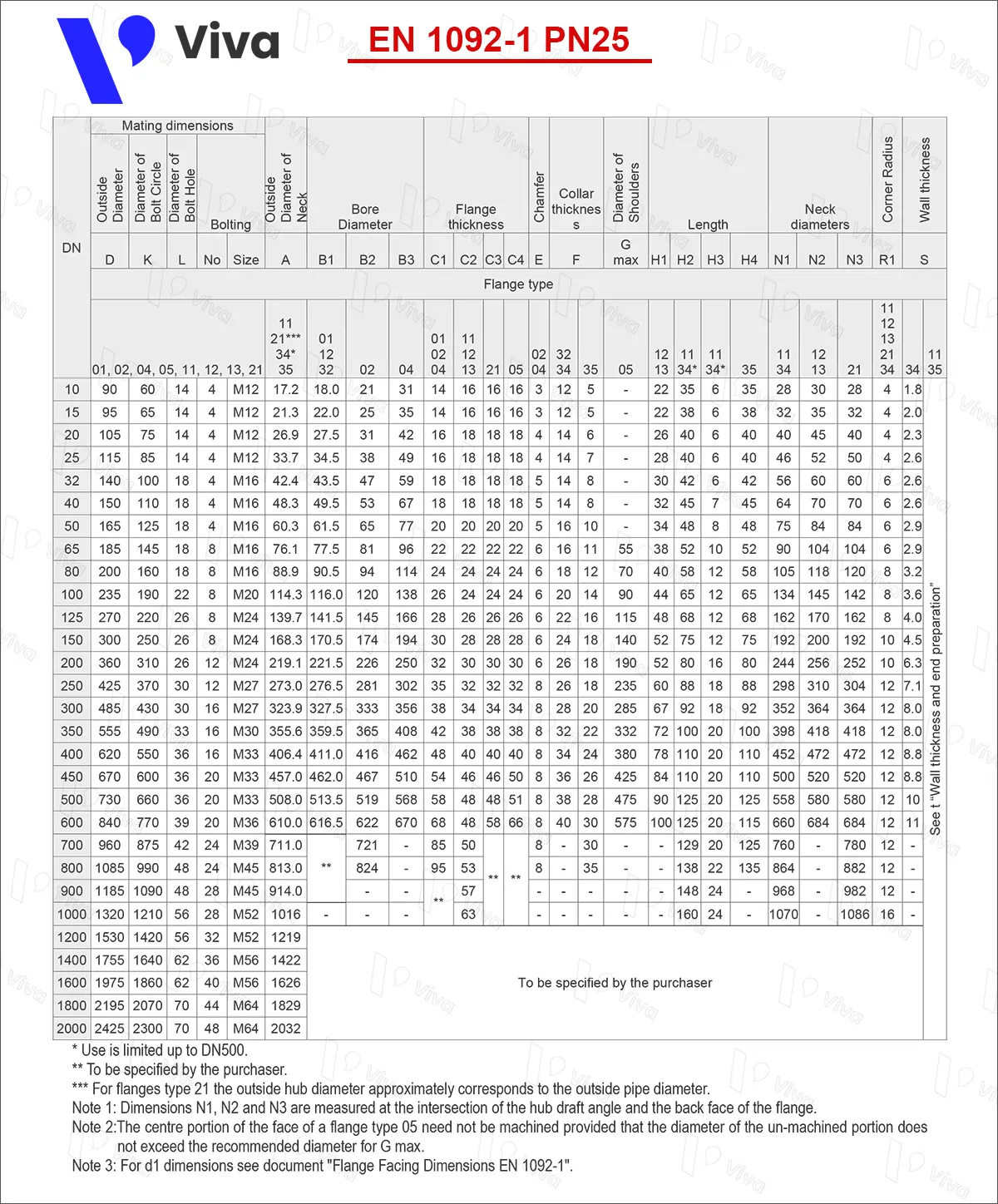

Flange Face Standards Chart EN 1092-1 PN6, PN10, PN16, PN25

- EN 1092-1 PN6:

- EN 1092-1 PN10:

- EN 1092-1 PN16:

- EN 1092-1 PN25:

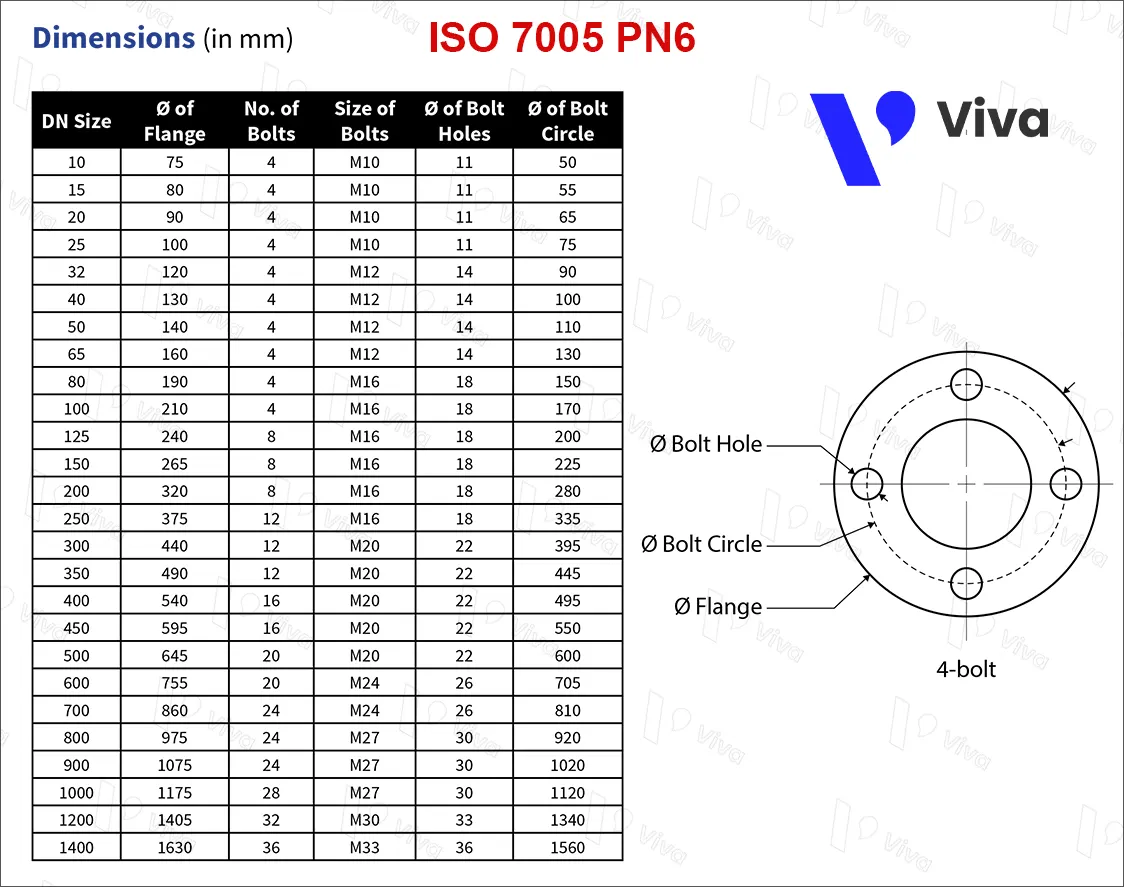

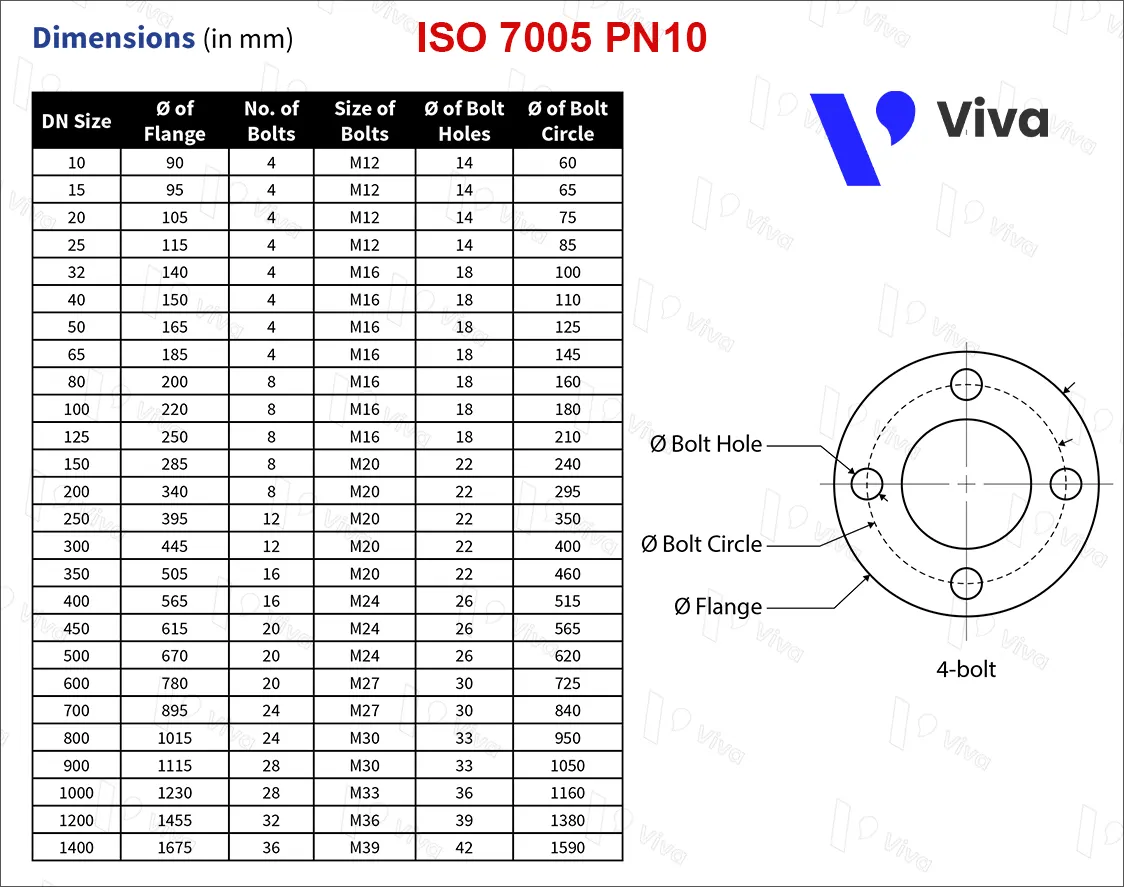

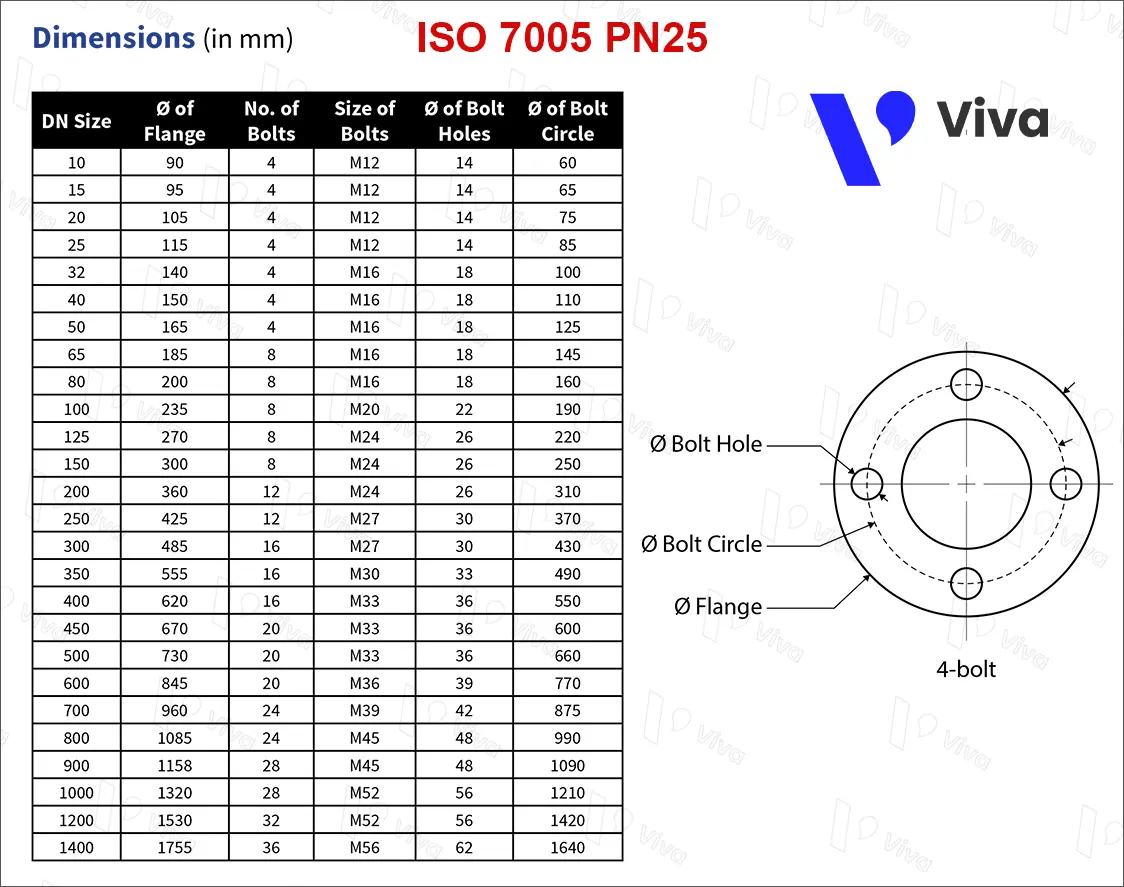

ISO 7005 PN6, PN10, PN

16, PN25 Flange Standards Comparison Table

- ISO 7005 PN6:

- ISO 7005 PN10:

- ISO 7005 PN16:

- ISO 7005 PN25:

What are Flange Standards?

Flange standards are technical regulations regarding the dimensions, shapes, and other related specifications of flanges. They are used to ensure the fit and tightness of flanged connections in piping systems, machinery, and industrial equipment.

6 most popular flange standards today include:

- JIS (Japan Industrial Standard)

- DIN (Deutsches Institut für Normung)

- BS (British Standards Institute)

- ANSI (American National Standards Institute)

- ISO (International Organization for Standardization)

- EN 1092-1 (European Union standard)

Flange standards can also be classified by material type, connection type, and maximum pressure they can withstand. Using the appropriate flange standards is essential to ensure the safety and efficiency of related systems.

JIS Flange Standard

JIS Flange Standard is a set of standards established by the Japanese Industrial Standards (JIS) to assess the compatibility of flanges in piping systems.

This set of standards includes various types of flanges such as JIS 5K, JIS 10K, JIS 16K, JIS 20K, JIS 30K, and JIS 40K, each with its own operating pressure and specific technical specifications.

JIS Flange Standard is widely used in the industry in Japan.

DIN Flange Standard

DIN Flange Standard is a set of standards established by the German Institute for Standardization (Deutsches Institut für Normung – DIN) to assess the compatibility of flanges in piping systems.

This set of standards includes various types of flanges such as DIN 2573, DIN 2576, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2673, and DIN 86029, each with its own operating pressure and specific technical specifications.

DIN Flange Standard is widely used in the industry in Germany.

BS Flange Standards

BS (British Standard) Flange is a system of size and pressure standards used for flanges in pipe applications. BS stands for “British Standards,” the official standards organization of the United Kingdom. The BS standards define the dimensions and pressure ratings of flanges to ensure compatibility and safety when connecting pipes and pipelines. The most common BS standards are BS 4504 and BS EN 1092.

ANSI Flange Standards

ANSI (American National Standards Institute) Flange Standards are a system of size and pressure ratings for flanges used in pipe and pipeline applications. ANSI is the abbreviation for the “American National Standards Institute,” a non-governmental organization based in the United States. ANSI standards define the dimensions and pressure ratings of flanges used to ensure compatibility and safety of pipes and pipelines when connected together. The most common ANSI standards are ANSI B16.5 and ANSI B16.47.

ISO Flange Standards

ISO (International Organization for Standardization) Flange Standards are international standards developed by the International Organization for Standardization (ISO). These standards specify the technical parameters of flanges, including dimensions, shapes, bolt hole numbers, and thickness, to ensure compatibility and safety of pipe and pipeline systems connected by flanges.

ISO Flange Standards also define the materials used to manufacture flanges and requirements for pressure and temperature of pipe and pipeline systems. ISO Flange Standards are widely applied worldwide and are among the important flange standards.

EN 1092-1 Flange Standards

EN 1092-1 Flange Standards are among the important flange standards of the European Union (EU). These standards define the technical parameters of flanges, including dimensions, shapes, bolt hole numbers, and thickness, to ensure compatibility and safety of pipe and pipeline systems connected by flanges. EN 1092-1 also specifies the materials used to manufacture flanges and requirements for pressure and temperature of pipe and pipeline systems. EN

1092-1 Flange Standards are widely used in industries such as oil and gas, chemical, food, and beverages.

How to Choose the Correct Standard Flange

To choose the correct standard flange, you need to follow these steps:

- Identify the type of pipe or equipment that needs to be connected using a flange.

- Inner Diameter (ID) and Outer Diameter (OD): These are important dimensions to ensure proper alignment between the flange and the pipe.

- Number of Holes and Bolt Circle Diameter: These are important parameters to choose the right quantity and size of bolts for the installation process.

- Working Pressure: This is the maximum pressure that the flange can withstand during operation.

- Flange Type: Common flange types include blind flange, slip-on flange, threaded flange, weld neck flange, etc. Choosing the appropriate flange type for a specific application will enhance the connection and durability of the system.

- Standard: Flanges can adhere to different standards such as ASME, DIN, JIS, BS, etc. It is important to select the appropriate standard according to the specific application requirements.

- Material: Flange materials can include steel, stainless steel, cast iron, brass, aluminum, etc. Choosing the suitable material for a specific application ensures the strength and stability of the flange.

- Ensure that the flange is manufactured by a reliable manufacturer and complies with all relevant regulations and quality standards.

- Inspect the flange before use to ensure compatibility and safety of the pipe and pipeline system.

The use of non-standard flanges can lead to serious consequences, including safety hazards, property damage, and even accidents for individuals.

Here are some types of flanges with different standards provided by Viva:

Can non-standard flanges be used interchangeably?

Non-standard flanges generally cannot be used interchangeably in a general sense and it always depends on each specific case. Each flange standard has different technical requirements, including size, shape, gap depth, and bolt hole spacing.

When replacing one type of flange with another, it is necessary to ensure the compatibility and safety of the connected pipes and equipment. Otherwise, using non-standard flanges can result in serious consequences, including compromising safety, property damage, and even fatal accidents.

Therefore, it is advisable to fully adhere to the specified standards when selecting and using flanges.

Our article provides reference tables for various flange size and thickness standards such as JIS, DIN, BS, and ANSI. These reference tables provide detailed information on flange dimensions, thickness, and pressure. Additionally, the article also offers information on the applications of flanges in various piping systems and industrial equipment. This article serves as a valuable resource for engineers, manufacturers, and individuals interested in flange size standards.